As long as there is no wind, you’re ok.That's lucky. It all looks good in the photos.

Plenty of dust to deal with here, but we're on a farm in the midst of a very dry season.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scott's RV14A: N52XL

- Thread starter rockitdoc

- Start date

Started back in to completing the QB wings. I have to close up the bottoms and install one access panel on the port side. I'll do the access panel first because it's pretty easy and I'm not sure how to reach all the rivets on the bottom skins, so something to think about.

On June 6 the wash primer was completed and the urethane primer was applied to the top of the wing. On June 7 the urethane primer was applied to the bottom of the wing. Harriet and I competed in the Glenwood Rally in the MGB over the weekend, then on June 11 I sanded the urethane down in preparation for painting.

I decided to paint the wingtips where the landing and position lights go silver to match the fuse. I did this yesterday, June 26. 4 hours. Today, June 27, I assembled the wingtips landing and position lights and attached the wingtips to the starboard wing. Harriet helped me put the flap on yesterday. 3 hours.

Cowl Bodywork Completed

Got all the bodywork done on the cowls with the side pins hidden under the RV14A plaque. Everything fits well and the pins and Skybolts all go in with no issues.

View attachment 31681

I used the same pin hinge covers as these on my RV7. What did you do with the ends of the hinge pins behind the covers? Thanks Kloot

Attached the baffles.

View attachment 31685

View attachment 31684

Started fitting the snorkel. It was too wide by 3/4". So, I cut it in half and took a section out in the middle and epoxied/floxed it back together. After some bodywork, it looks pretty good. Primed it today and will paint it tomorrow.

View attachment 31683

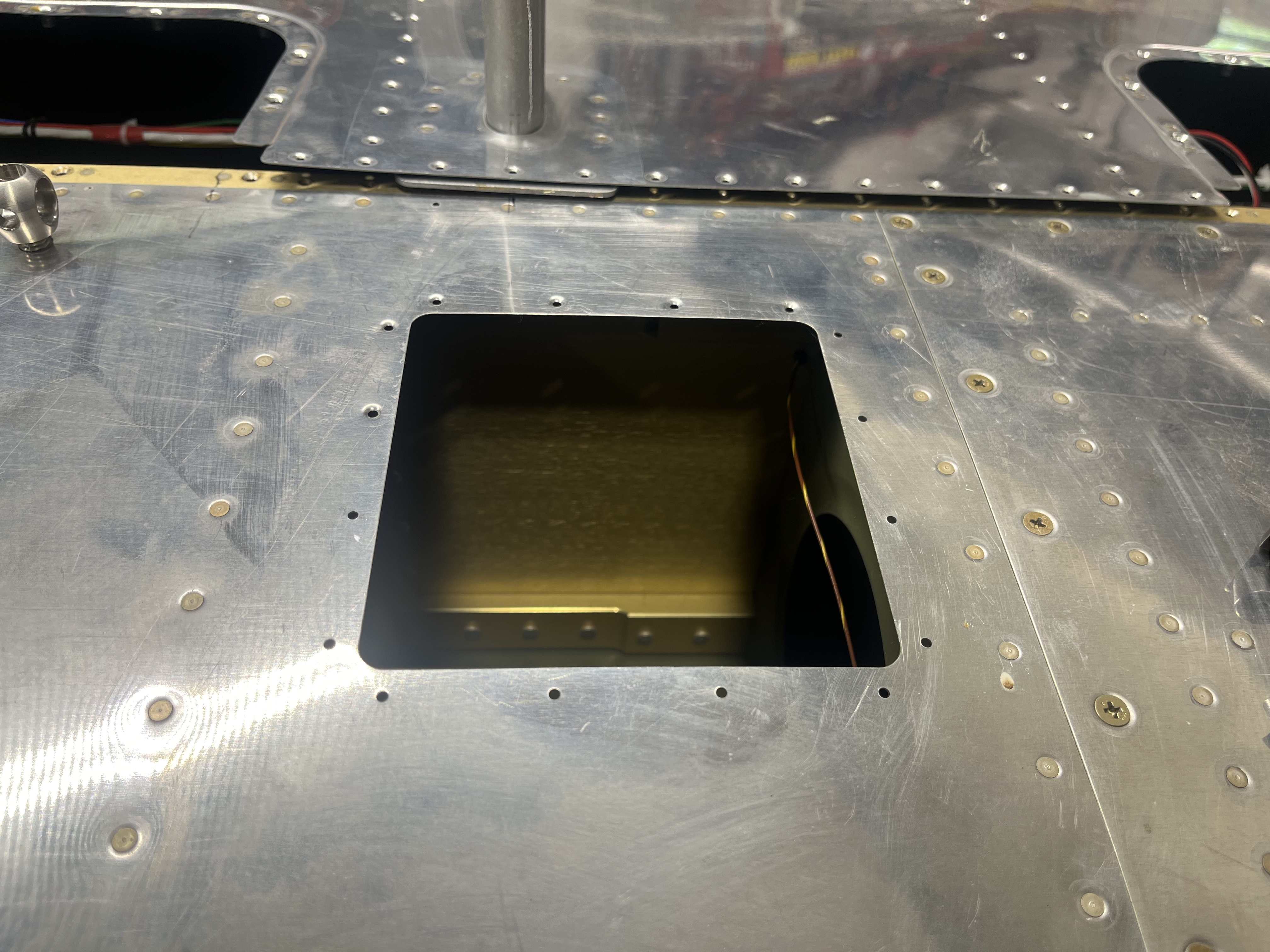

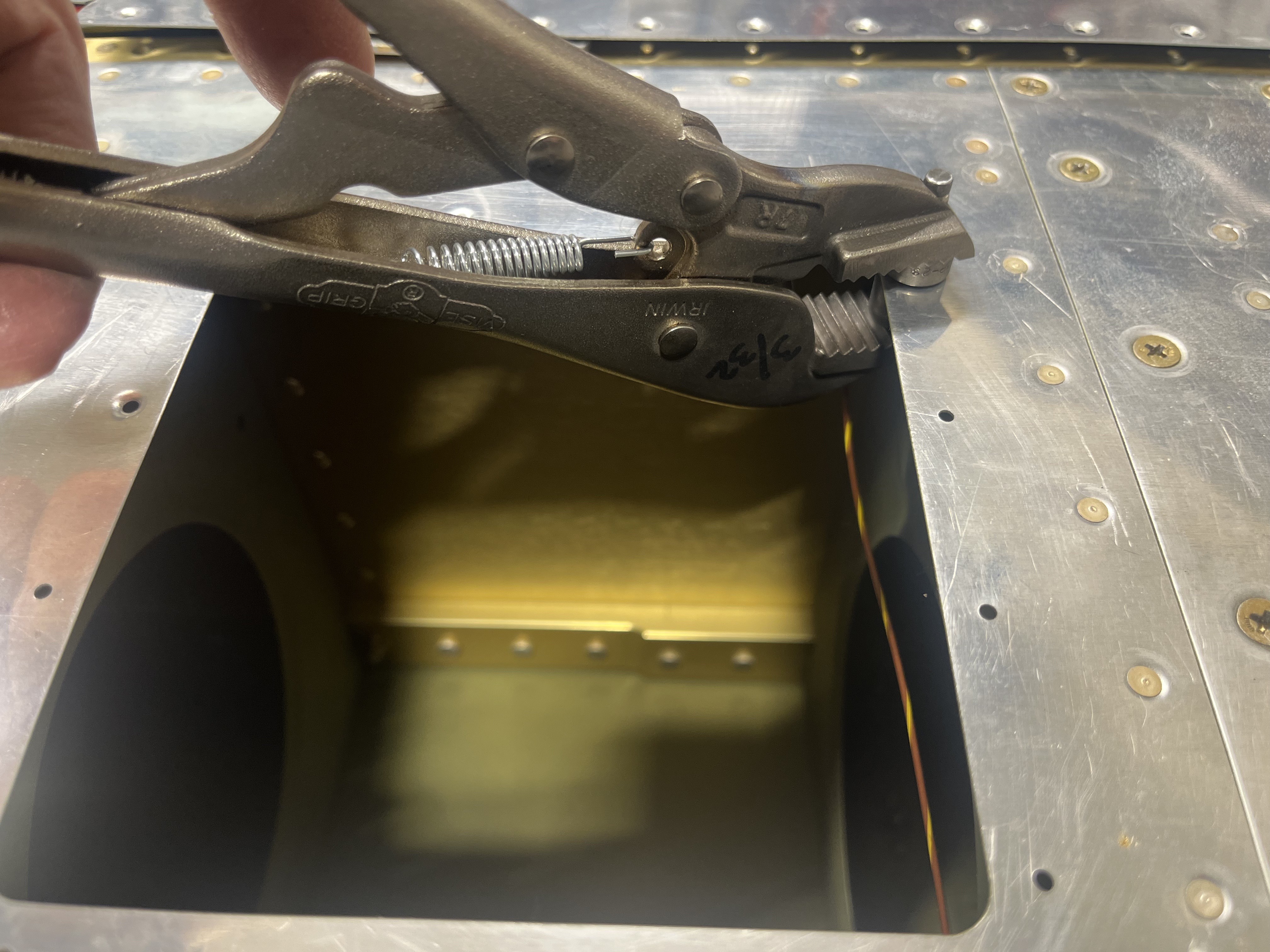

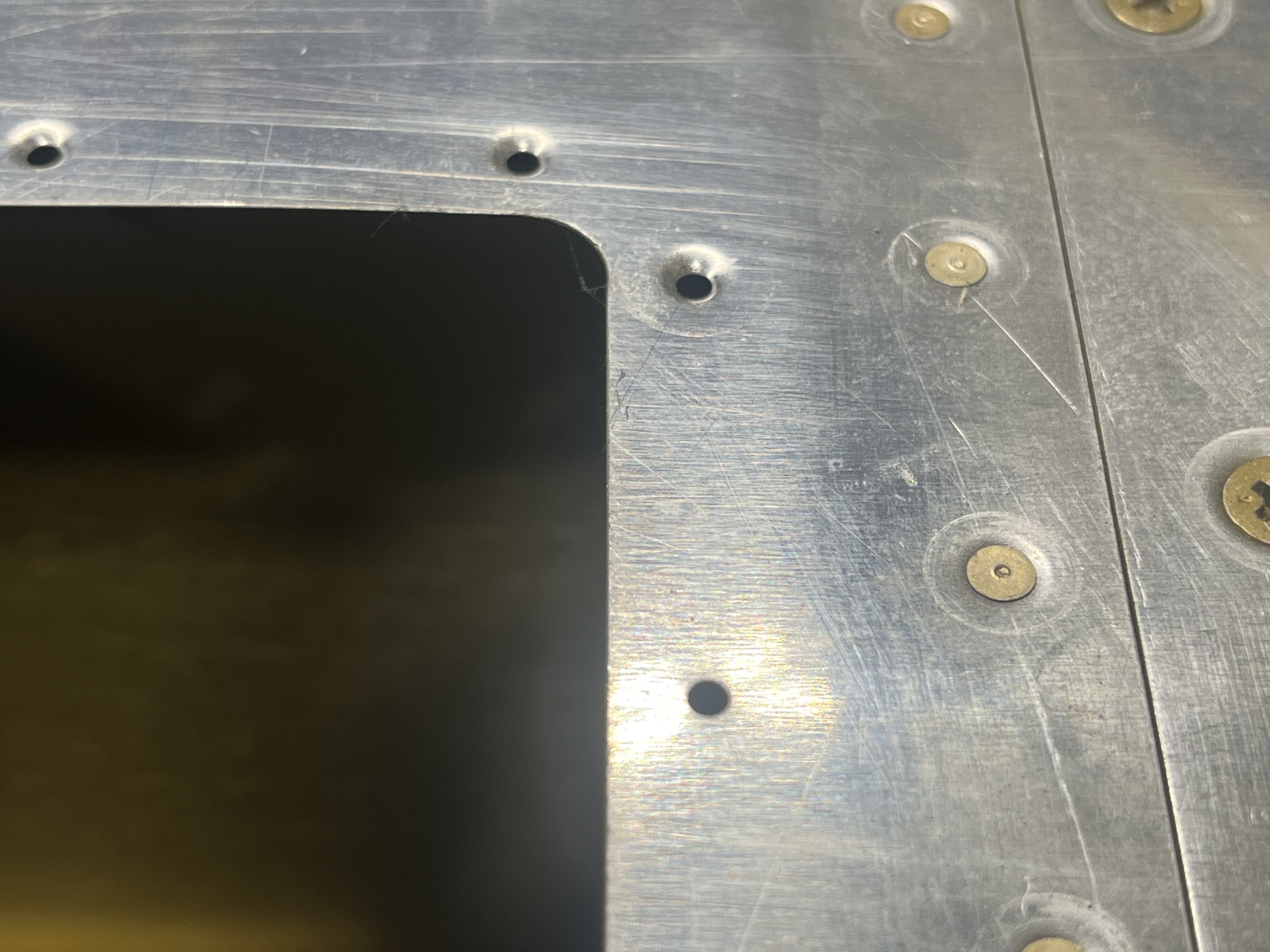

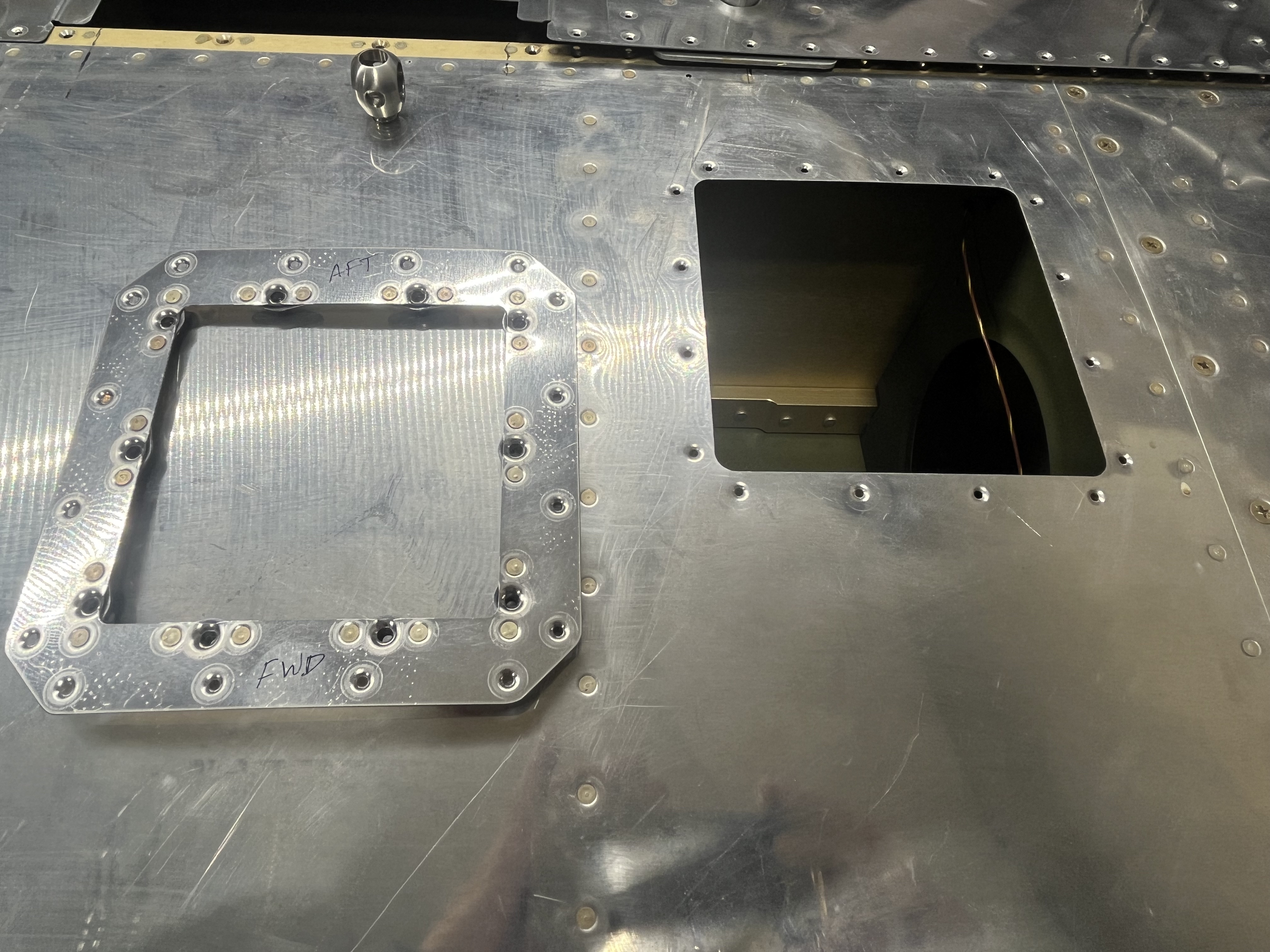

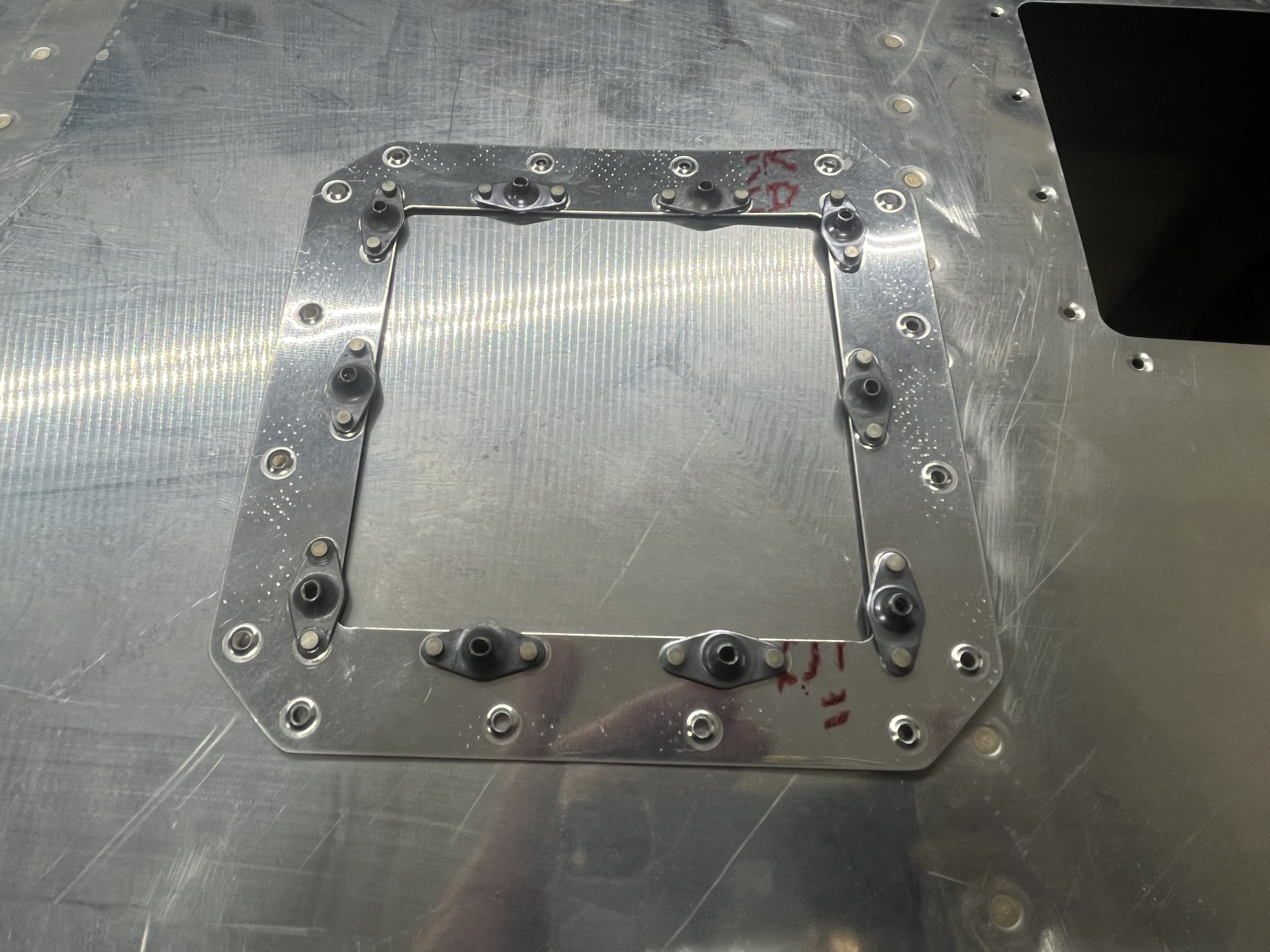

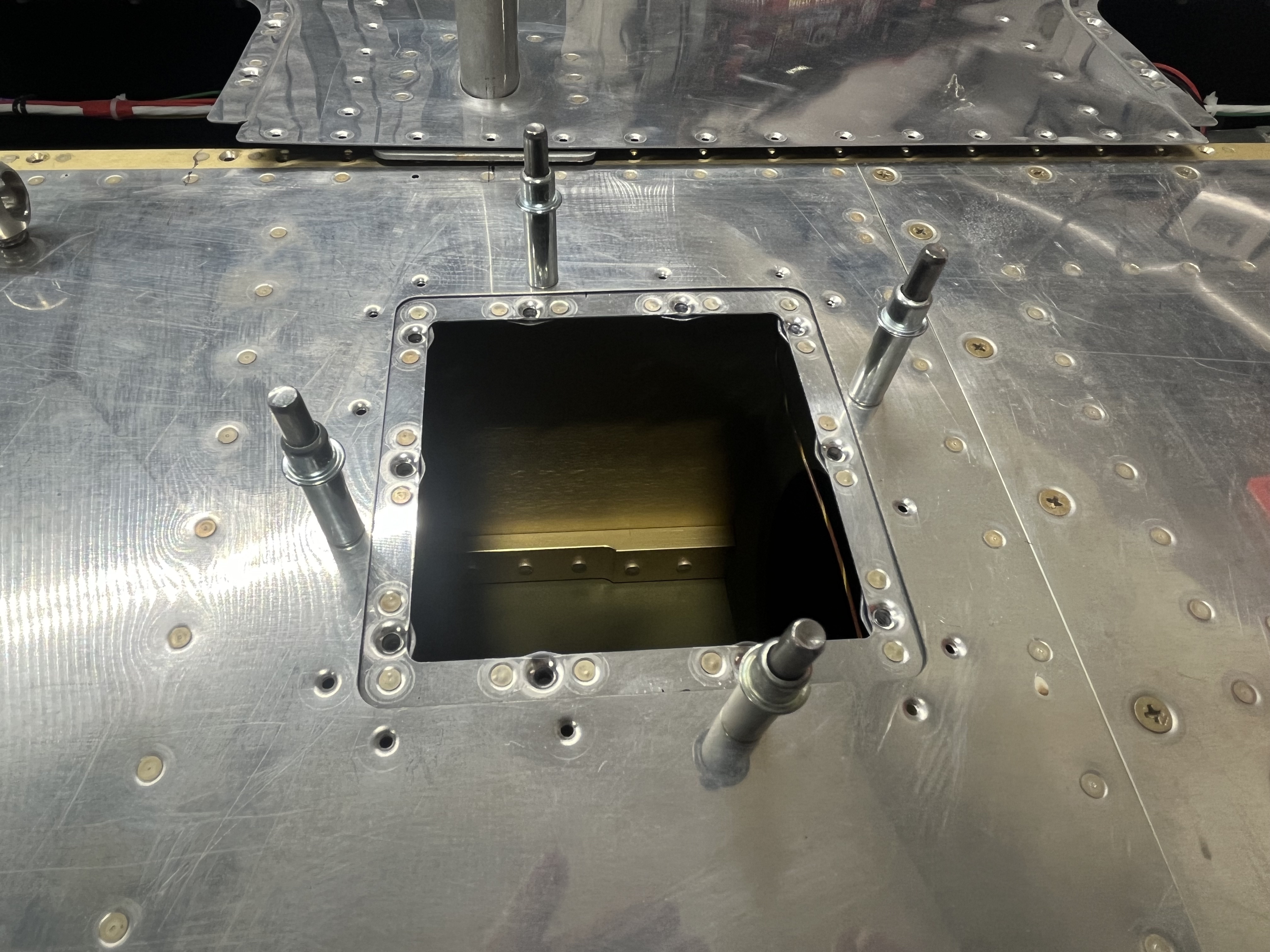

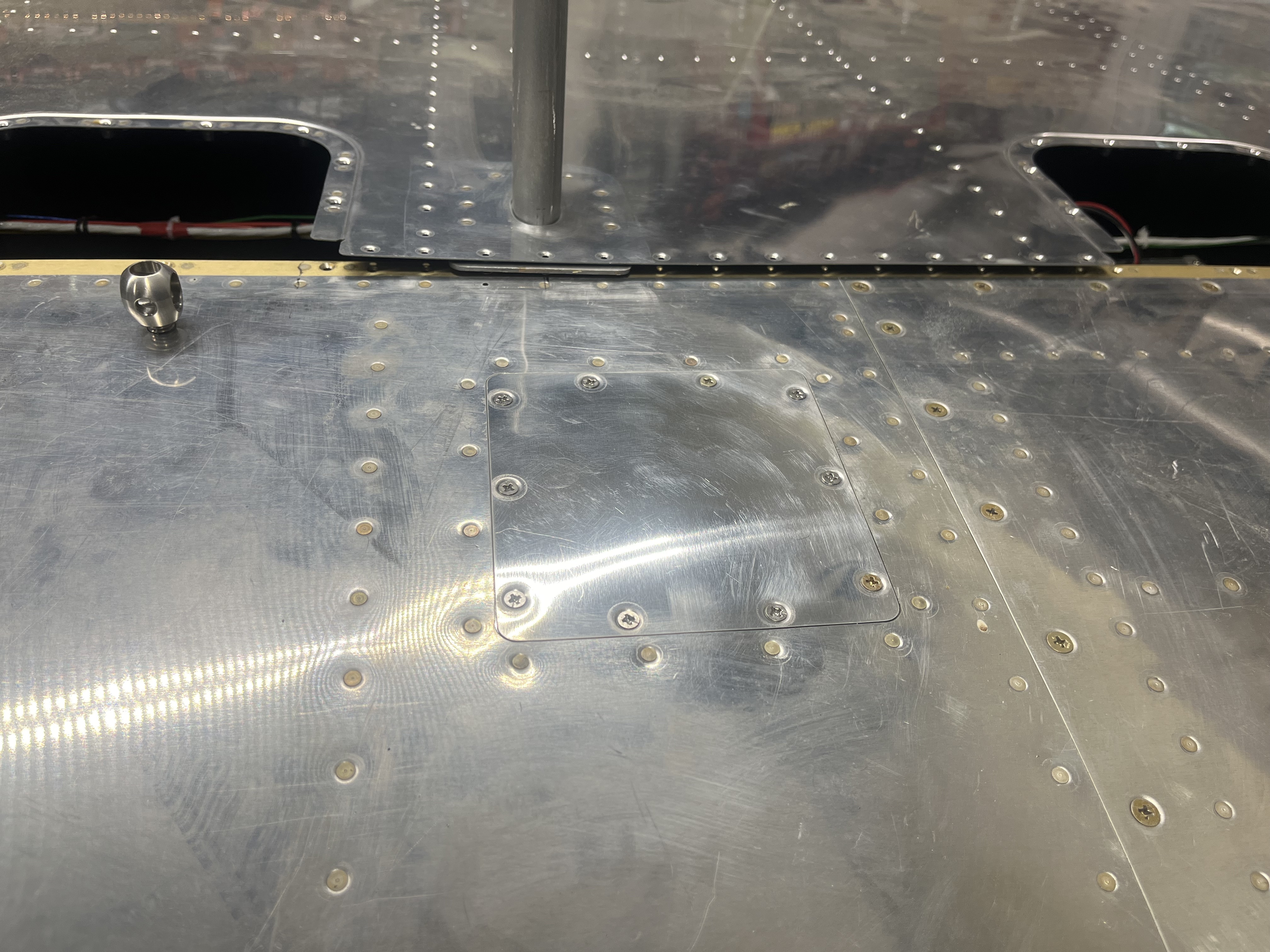

I decided to add an extra access port in the bottom of the port wing. Two reasons: 1) obtain better access to the pitot and AOA hoses and wiring of the pitot heater and, 2) obtain better access to rivets for riveting the pitot tube and the forward-most skin rivets which otherwise can't be reached (at least by me).

Thanks to Wirejock for the hole cutter. It did the trick.

Thanks to Wirejock for the hole cutter. It did the trick.

Thank you Scott. That’s what I’m going to do. Didn’t know if there was a better mousetrap.Kloot,

I bent the pin around to form a loop. This allows pulling it out easier.

Scott

wirejock

Well Known Member

Glad it worked. I never purchased, but this thing is supposed to be the "bee's knees."

www.malcotools.com

www.malcotools.com

“Gold Standard” Sheet Metal Hole Cutters and Cutter Bits - Malco Tools

Distinctive gold Bits, Bearings and Pivot Pin signify the longest lasting, fastest cutting, easiest adjusting solution for cutting holes in sheet metal. Up to 20-gauge (1.02 mm) capacity in galvanized steel.

Here's what mine looks like with the trick cover removed.Thank you Scott. That’s what I’m going to do. Didn’t know if there was a better mousetrap.

Attachments

I'm back! Not much to report in past month or so. Just cutting and buffing paint and moving everything except fuse to the hangar. There is a LOT of real estate to cut and buff! Not much like a car.

Anyway, working on bleeding brakes which is way a lot of fun. Needed a break. So, I installed the Aircraft Specialty alternate air door. Very nice piece, as usual from these guys. Way better than the OEM door. It took a little trimming to make it fit but it works very slick.

Anyway, working on bleeding brakes which is way a lot of fun. Needed a break. So, I installed the Aircraft Specialty alternate air door. Very nice piece, as usual from these guys. Way better than the OEM door. It took a little trimming to make it fit but it works very slick.

I presume you mean the 90 degree coming off the head? I agree. I never liked the clamp on the nut, either. Thanks. SDuring a review by my bud who is an A&P, he suggested I move the Adel clamp off the flare nut to the fitting. Reason was the fitting is less likely to turn than the nut.

I have no idea how that nut could spun off.. the adel clamp works like a wire safety to my perception... it is tight and the alternate air cable wont just let the assembly spin. But do what the A&P says.During a review by my bud who is an A&P, he suggested I move the Adel clamp off the flare nut to the fitting. Reason was the fitting is less likely to turn than the nut.

The nut doesn’t have to spin off, just get loose for a leak to occur. Probably would never loosen the nut but not a good practice. And if I get a DAR like Mel, one less thing for him to find.I have no idea how that nut could spun off.. the adel clamp works like a wire safety to my perception... it is tight and the alternate air cable wont just let the assembly spin. But do what the A&P says.

I wasn't happy with the paintwork I did on the lower cowl after cutting and buffing it. So, rather than wish I had redone it when it was in the shop, I sanded it all down and repainted it. This time, I got the lighting so I could see what I was painting (important) and it turned out much better. A little cutting and buffing will make this part look like the upper bits. Almost there........!

PaulvS

Well Known Member

How did you go about painting the rest of the fuselage? I'm thinking about how to tackle it. Seems like it is going to be a challenge to paint the underside and have enough space to get in with a creeper. Also to be able to paint a complete "lap" around the fuselage before the paint flashes off and makes it difficult to avoid overspray settling on. Where on the fuse did you start and end spraying to meet up with the "wet edge"?I wasn't happy with the paintwork I did on the lower cowl after cutting and buffing it. So, rather than wish I had redone it when it was in the shop, I sanded it all down and repainted it. This time, I got the lighting so I could see what I was painting (important) and it turned out much better. A little cutting and buffing will make this part look like the upper bits. Almost there........!

View attachment 69656

Cheers

Paul

Paul,How did you go about painting the rest of the fuselage? I'm thinking about how to tackle it. Seems like it is going to be a challenge to paint the underside and have enough space to get in with a creeper. Also to be able to paint a complete "lap" around the fuselage before the paint flashes off and makes it difficult to avoid overspray settling on. Where on the fuse did you start and end spraying to meet up with the "wet edge"?

Cheers

Paul

Painting the belly was not as difficult as it might seem, although it is a lot of real estate. The fuse is pretty high up, so a creeper is all that is needed, although I just sat on the floor of my shop and slid around. I adjusted my paint with slow flashing reducer and painted at an average temperature of 65F, so by continually moving, overspray was kept at a minimum. I use an Anest Iwata LPH400 gun and orange air cap for colors and silver cap for clears. I painted the centerline of the belly and worked outward. That way, the overlap orange peel is at the very center, underneath, and less noticeable. It's no different than the way you would shoot a large car. Some cutting and buffing is inevitable, though, to get a perfectly flat finish if that is the goal.

PaulvS

Well Known Member

Paul,

Painting the belly was not as difficult as it might seem, although it is a lot of real estate. The fuse is pretty high up, so a creeper is all that is needed, although I just sat on the floor of my shop and slid around. I adjusted my paint with slow flashing reducer and painted at an average temperature of 65F, so by continually moving, overspray was kept at a minimum. I use an Anest Iwata LPH400 gun and orange air cap for colors and silver cap for clears. I painted the centerline of the belly and worked outward. That way, the overlap orange peel is at the very center, underneath, and less noticeable. It's no different than the way you would shoot a large car. Some cutting and buffing is inevitable, though, to get a perfectly flat finish if that is the goal.

Thanks Scott

The LPH400 looks like a nice gun and the HTE should help with overspray reduction I expect.

The belly is a big expanse especially under the cockpit and baggage area. I can't really visualize how to work underneath and then come out and up the sides while spraying as it seems there would be a bit of scrambling to get out from underneath to spray up the sides. I'm thinking of maybe spraying the belly first and then masking it off when it is dry (along the natural seam lines) before spraying the fusealage sides and top.

p.s. if I can paint early in the day the temps will be cooler so it doesn't flash off too fast, I will also try slow reducer and activator, the down side of that will be more potential for runs and dust getting in...

Last edited: