I don't typically post accident links, but this sort of component failure could easily be present in many RV's. The pilot was doing a preflight with the ignition key in his pocket...but he still had a hot mag.

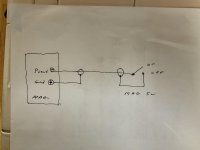

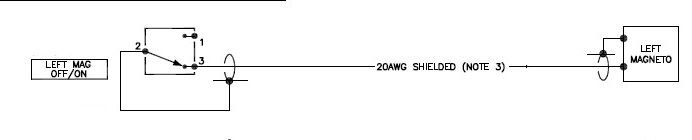

I'm not a fan of rotary ignition switches, and always recommend toggles. However, if it's what you want, fine. Just be sure to check it on a regular basis, not just for reliable p-lead grounding, but for key retention in all positions other than off.

http://www.kathrynsreport.com/2019/07/propeller-contact-with-person-cessna.html

BTW, I was once standing at the nose of a Baby Ace with two other pilots and an FAA Master Mechanic, generally shooting the breeze. Somebody moved the prop just a fuzz, the impulse clicked, and it started. There were guys on both sides of the prop disk. It missed all of us by inches.

I'm not a fan of rotary ignition switches, and always recommend toggles. However, if it's what you want, fine. Just be sure to check it on a regular basis, not just for reliable p-lead grounding, but for key retention in all positions other than off.

http://www.kathrynsreport.com/2019/07/propeller-contact-with-person-cessna.html

BTW, I was once standing at the nose of a Baby Ace with two other pilots and an FAA Master Mechanic, generally shooting the breeze. Somebody moved the prop just a fuzz, the impulse clicked, and it started. There were guys on both sides of the prop disk. It missed all of us by inches.