I think I will need this to be explained to me. What is the intent for this hole?Here's my new S10 housing with an oil vent (the reusable version of poking a nail in the filter). Beautiful craftsmanship.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Champion Oil filter - CH48101-1

- Thread starter dbaflyer

- Start date

I think I will need this to be explained to me. What is the intent for this hole?

The main intent of it is to minimize oil mess during changes. It does this by providing a vent port, or vacuum breaker, if installed with the port facing upward, or a drain port with the port facing down. If installed horizontally, it still provides a vent port, but may or may not be worth it to you. In all cases, it allows you to drain the oil from the filter in a controlled manner.

I experience essentially no oil dripped on the engine at change.

The port threads are 7/16-20 and work with an AN814-4 plug which has an o-ring.

Attachments

The main intent of it is to minimize oil mess during changes. It does this by providing a vent port, or vacuum breaker, if installed with the port facing upward, or a drain port with the port facing down. If installed horizontally, it still provides a vent port, but may or may not be worth it to you. In all cases, it allows you to drain the oil from the filter in a controlled manner.

I experience essentially no oil dripped on the engine at change.

The port threads are 7/16-20 and work with an AN814-4 plug which has an o-ring.

Nice mod and thanks for explaining. Are you planning on putting a safety wire on the plug?

This looks like it was machined to accommodate for the o-ring.

Nice mod and thanks for explaining. Are you planning on putting a safety wire on the plug?

This looks like it was machined to accommodate for the o-ring.

I do safety wire the plug through the filter housing to the filter base, same piece of wire...easy.

I do it out of habit, although I've never actually had an oil filter come loose on anything I've installed one on, including an enduro bike which gets much more vibration and pounding than any airplane ever will...but that's a topic for the "to safety wire, or not to safety wire your oil filter" debate list and probably not what you're asking.

The plug opening is in fact machined for an o-ring. It was milled to the dimensional standard for an AN814-4 plug, but not anything I take credit for - I bought it from K&P Engineering that way. (usaoilfilters.com)

Thanks.... You just saved me $30.00 and free shipping.....

I see the ECU ships with the nipple, which I don’t need? I am using an Airwolf remote setup what has the male threaded for the filter to screw on already

Attachments

Last edited:

Ron,

Do you have the part number for the O-Ring used on the AN814-4 Plug. I like the idea of draining the oil in a controlled fashion.

Thanks

Gary

The o-ring is 3/8" ID and 1/16" width. MS28775-012 is the right PN.

The controlled drain is definitely nice; little to none oil drips.

Last edited:

S15 and McMasters Carr nipple

So I understand that S15 and a 3/4 16 nipple will be the unit for a lycoming 0360. Will one of these McMaster Carr nipples work and if so what is better or does it matter?

So I understand that S15 and a 3/4 16 nipple will be the unit for a lycoming 0360. Will one of these McMaster Carr nipples work and if so what is better or does it matter?

Attachments

dpansier

Well Known Member

So I understand that S15 and a 3/4 16 nipple will be the unit for a lycoming 0360. Will one of these McMaster Carr nipples work and if so what is better or does it matter?

The two examples shown will not work as they are NPT threads, the filter requires a 3/4-16 straight thread nipple.

The two examples shown will not work as they are NPT threads, the filter requires a 3/4-16 straight thread nipple.

You can buy one here, or cut one out of an existing oil filter.

https://www.pegasusautoracing.com/productselection.asp?Product=1234

Attaching the nipple to the filter...

Attaching the nipple to the new filter....Is any kind of thread locker used or do you just use enough torque to keep it in place over the torque needed (18-20 ft #'s) to seat the filter?

So screw the nipple in good and tight (say 30#'s) and count on friction keeping it in when it comes time to unscrew the assembly or use something to make sure it does?

TIA,

Rob

Attaching the nipple to the new filter....Is any kind of thread locker used or do you just use enough torque to keep it in place over the torque needed (18-20 ft #'s) to seat the filter?

So screw the nipple in good and tight (say 30#'s) and count on friction keeping it in when it comes time to unscrew the assembly or use something to make sure it does?

TIA,

Rob

I removed a nipple from a used tempest 48110-2 filter and learned that the side of the nipple installed in the filter has NPT threads about 3/8” in length. The nipple was secured very tight in the filter and took quite an effort to remove it. The other side of the nipple was the 3/4 16 straight threads.

I looked at the Pegasus nipple and it has 3/8” on one side and more than 3/4” on the other side. I was concerned that the 3/8” side would not be long enough and the other side would be too long. The tempest filter has 3/4” long threads that screw into the engine case.

I purchased a nipple from usaoilfilters which sells the S15 filters and it is used for the S15 filter. Since the threads are straight on both sides, I am also unsure how the nipple is secured. Is the nipple supposed to be permanent in the case or the filter and if so what holds the nipple permanently?

I looked at the Pegasus nipple and it has 3/8” on one side and more than 3/4” on the other side. I was concerned that the 3/8” side would not be long enough and the other side would be too long. The tempest filter has 3/4” long threads that screw into the engine case.

I purchased a nipple from usaoilfilters which sells the S15 filters and it is used for the S15 filter. Since the threads are straight on both sides, I am also unsure how the nipple is secured. Is the nipple supposed to be permanent in the case or the filter and if so what holds the nipple permanently?

The controlled drain is definitely nice; little to none oil drips.

Will a horizontal filter drain into the engine if this plug is loosened? Or would I only serve to speed the draining of filter oil once the housing is loose?

Will a horizontal filter drain into the engine if this plug is loosened? Or would I only serve to speed the draining of filter oil once the housing is loose?

Mounted horizontally, it should still offer a vent path to any oil held in the filter and allow it to fully drain. Unlike a vertical installation, you might get some drips, but at least they'll be at the tip of the filter under the plug and easy to catch.

The AN814 plug has a small vent port in it, so you do not need to remove it completely, but rather only turn out a couple threads to expose the vent port.

Roadjunkie1

Well Known Member

Where does the fitting go?

I think getting the fitting from USA or other vendors would be preferable to mangling one out of a filter...IMHO...

Does the fitting go on the filter or the engine? I think it would be your choice depending on several things:

1) it is easier to put the filter on with the fitting on the filter or on the engine? There may be no difference in the hassle factor. The Champion etc filters have the "fitting" on the filter so that may be where you want it.

2) The center of the filter needs to be removed to clean the filter element and the fitting on the filter may be in the way. Or could help one snap the holding fitting out of place to remove the element.

3) Thread Lock (red vs blue) can help secure the fitting on the engine (or filter). If you are inclined to remove it from the filter to facilitate cleaning, blue would be better. It may be tight enough you don't need anything. It may be a YES vote for safety wiring the filter to ease one's mind.

If the fitting leaks.....well, it would be a minor leak and be INSIDE the filter and should not be an issue. Thus, thread sealant may not be necessary. The 18ft/lb (or whatever you torque it to) should put enough tension on the fitting it isn't going to go anywhere....

YMMV; IMHO......

I purchased a nipple from usaoilfilters which sells the S15 filters and it is used for the S15 filter. Since the threads are straight on both sides, I am also unsure how the nipple is secured. Is the nipple supposed to be permanent in the case or the filter and if so what holds the nipple permanently?

I think getting the fitting from USA or other vendors would be preferable to mangling one out of a filter...IMHO...

Does the fitting go on the filter or the engine? I think it would be your choice depending on several things:

1) it is easier to put the filter on with the fitting on the filter or on the engine? There may be no difference in the hassle factor. The Champion etc filters have the "fitting" on the filter so that may be where you want it.

2) The center of the filter needs to be removed to clean the filter element and the fitting on the filter may be in the way. Or could help one snap the holding fitting out of place to remove the element.

3) Thread Lock (red vs blue) can help secure the fitting on the engine (or filter). If you are inclined to remove it from the filter to facilitate cleaning, blue would be better. It may be tight enough you don't need anything. It may be a YES vote for safety wiring the filter to ease one's mind.

If the fitting leaks.....well, it would be a minor leak and be INSIDE the filter and should not be an issue. Thus, thread sealant may not be necessary. The 18ft/lb (or whatever you torque it to) should put enough tension on the fitting it isn't going to go anywhere....

YMMV; IMHO......

Here's my new S10 housing with an oil vent (the reusable version of poking a nail in the filter). Beautiful craftsmanship.

I can not find an S10 housing on the USA Oil Filters website, only a C10 that looks like what is in your photos. Is the housing C10 what you are using? Also, if you care to share, which filter element are you using? Thanks. I like the ability to vent and drain the filter prior to removal. Dave

I can not find an S10 housing on the USA Oil Filters website, only a C10 that looks like what is in your photos. Is the housing C10 what you are using? Also, if you care to share, which filter element are you using? Thanks. I like the ability to vent and drain the filter prior to removal. Dave

Sorry for the confusion Dave - that's a typo on my part. I corrected my original post - thanks for catching that.

C10 is the housing you want.

The FE15 filter element has a 3/4-16 thread and works with this housing as well.

Here is the parts to replicate my installation:

- C10 Housing

- FE15 Filter element

- QR2 quadring

- FERS1 spring

(from ACS or other parts vendor)

- AN814-4 plug

- MS28775-012 o-ring, 3/8" ID and 1/16" width.

Last edited:

Sorry for the confusion Dave - that's a typo on my part. I corrected my original post - thanks for catching that.

C10 is the housing you want.

The FE15 filter element has a 3/4-16 thread and works with this housing as well.

Here is the parts to replicate my installation:

- C10 Housing

- FE15 Filter element

- QR2 quadring

- FERS1 spring

(from ACS or other parts vendor)

- AN814-4 plug

- MS28775-012 o-ring, 3/8" ID and 1/16" width.

Thank you Ron!

K&P Engineering Oil filter

If you have used a K&P Engineering S15 oil filter unit, please give us your review and comparison with a Champion or Tempest filter, how long you have used the K&P units, and if you have examined the Champion or Tempest filters, have you observed a difference in the debris collected between the S15 and the paper filter elements. From your observation, which appeared to collect more debris in the filter element.

If you have used a K&P Engineering S15 oil filter unit, please give us your review and comparison with a Champion or Tempest filter, how long you have used the K&P units, and if you have examined the Champion or Tempest filters, have you observed a difference in the debris collected between the S15 and the paper filter elements. From your observation, which appeared to collect more debris in the filter element.

erich weaver

Well Known Member

Just received and installed the S15 unit from ECS Tuning - $159 and free shipping. Dead simple installation and seems to be working as advertised although it will be a few months before I go through an oil change with it. With the current cost of oil filters at $32 each plus shipping, supply problems, and the hassle and mess of cutting them open at each oil change, I was happy to make the switch.

Those are great reasons and, I also just purchased an S15. We are all concerned and protective of our engines. K&P makes great claims and if one does a little research, others have inferred that they may have selected test that favor their product. I understand that there are many folks in our community that have used this type filter for quiet awhile and if anyone can enlighten us about findings pro or con with paper filter element vs. the screen element.

I bit the bullet and ordered the Challenger aviation model. Yes I know it is nearly the same, but anyway I ordered from Spruce after a lot of research.

Ships September 6th

I have not heard one bad thing about the system. And the number of early engine break-in oil changes that take place I figured why not start with one

Ships September 6th

I have not heard one bad thing about the system. And the number of early engine break-in oil changes that take place I figured why not start with one

sbalmos

Well Known Member

This is highly unscientific and anecdotal, possibly to the point of making DanH cry. But last night / this morning I completed my first oil change after installing my K&P S15. For reference, it was installed at my last oil change on 4/30, and between then and now I put 31.2h on it. The engine now has 200h SMOH. Like my Tempests before, the filter is installed on a Casper 45* adapter. A few observations...

1. In-flight, the oil was an avg of 3*F cooler, likely from the metal housing.

2. Pulling off the filter is /much/ cleaner, IMO. Even after punching holes in the top of my Tempest and letting it drain overnight, I still had quite a bit of excess oil still in the filter when I spun it off. The K&P had practically none remaining.

3. The metallic screen made it much easier to see the carbon greebles and little bits of debris, when holding the screen assembly in your hand and reflecting it in the light. Even more so when washing it off.

4. The magnet at the base of the filter definitely picked up the ferrous sludge dust nicely.

5. Cleanup is easy. A few spurts of brake cleaner inside through it, much less than what K&P shows in their cleaning video. A good wash with some Dawn and strong rinse-out with cold water in the chapter hangar utility tub. Compressed air to blow the water out, and now it's finishing air-drying as I wash the thick cover of Oshkosh Dust [tm] off the plane.

Honestly can't tell whether the filter pulled out more, less, etc. Looks to do just as good a job as the Tempests for me, and that's what matters. We'll see what Blackstone says eventually, whether they notice a difference.

1. In-flight, the oil was an avg of 3*F cooler, likely from the metal housing.

2. Pulling off the filter is /much/ cleaner, IMO. Even after punching holes in the top of my Tempest and letting it drain overnight, I still had quite a bit of excess oil still in the filter when I spun it off. The K&P had practically none remaining.

3. The metallic screen made it much easier to see the carbon greebles and little bits of debris, when holding the screen assembly in your hand and reflecting it in the light. Even more so when washing it off.

4. The magnet at the base of the filter definitely picked up the ferrous sludge dust nicely.

5. Cleanup is easy. A few spurts of brake cleaner inside through it, much less than what K&P shows in their cleaning video. A good wash with some Dawn and strong rinse-out with cold water in the chapter hangar utility tub. Compressed air to blow the water out, and now it's finishing air-drying as I wash the thick cover of Oshkosh Dust [tm] off the plane.

Honestly can't tell whether the filter pulled out more, less, etc. Looks to do just as good a job as the Tempests for me, and that's what matters. We'll see what Blackstone says eventually, whether they notice a difference.

Attachments

Walt

Well Known Member

2. Pulling off the filter is /much/ cleaner, IMO. Even after punching holes in the top of my Tempest and letting it drain overnight, I still had quite a bit of excess oil still in the filter when I spun it off. The K&P had practically none remaining.

.

Although the above sounds great from a less-mess standpoint, it also means that at each start up the filter is empty and has to get re-filled before oil pressure starts to build. A big deal, probably not. Pretty sure the Tempest/Champions have check valves to prevent this.

Last edited:

What is the micron rating of the K&P filter? Spent 45-minutes searching for the micron rating of this filter.

Champion publishes that their filter is 25 micron and Champion claims that the Tempest filter is not as good as theirs at 40 micron.

The screen mesh in the K&P filter looks finer than the standard Lycoming screen but the screen will require the user to do 25-hour oil changes and not get the 50-hours between oil changes with leaded fuel recommended for the disposal filter Lycoming recommends. A switch to unleaded fuel will change Lycoming's recommended oil filter change to 100 hours for the disposable spin on oil filter.

Users of the K&P filter will have oil to dispose of ever 25-flight hours and solvent to dispose of that they use to clean the screen filter.

Champion publishes that their filter is 25 micron and Champion claims that the Tempest filter is not as good as theirs at 40 micron.

The screen mesh in the K&P filter looks finer than the standard Lycoming screen but the screen will require the user to do 25-hour oil changes and not get the 50-hours between oil changes with leaded fuel recommended for the disposal filter Lycoming recommends. A switch to unleaded fuel will change Lycoming's recommended oil filter change to 100 hours for the disposable spin on oil filter.

Users of the K&P filter will have oil to dispose of ever 25-flight hours and solvent to dispose of that they use to clean the screen filter.

What is the micron rating of the K&P filter? Spent 45-minutes searching for the micron rating of this filter.

Champion publishes that their filter is 25 micron and Champion claims that the Tempest filter is not as good as theirs at 40 micron.

The screen mesh in the K&P filter looks finer than the standard Lycoming screen but the screen will require the user to do 25-hour oil changes and not get the 50-hours between oil changes with leaded fuel recommended for the disposal filter Lycoming recommends. A switch to unleaded fuel will change Lycoming's recommended oil filter change to 100 hours for the disposable spin on oil filter.

Users of the K&P filter will have oil to dispose of ever 25-flight hours and solvent to dispose of that they use to clean the screen filter.

Condor - you can find K&P’s discussion of microns and filtration comparison to paper in their FAQ’s:

https://kandpengineering.com/faqs/

I have a call in to Challenger (who site K&P as their manufacturer at the bottom of their web page) asking if they recommend 25 or 50 - this screen is a totally different animal than the old Lycoming screen, and K&P claims better filtration than with paper, so the answer isn’t obvious. I sort of doubt that they will take a position on it, and I am sure Lycoming won’t…ahh, the joys of “experimental”….

Paul

Condor - you can find K&P’s discussion of microns and filtration comparison to paper in their FAQ’s:

https://kandpengineering.com/faqs/

I have a call in to Challenger (who site K&P as their manufacturer at the bottom of their web page) asking if they recommend 25 or 50 - this screen is a totally different animal than the old Lycoming screen, and K&P claims better filtration than with paper, so the answer isn’t obvious. I sort of doubt that they will take a position on it, and I am sure Lycoming won’t…ahh, the joys of “experimental”….

Paul

From their FAQ:

"The medical grade stainless steel cloth that we use is consistent across the entire media surface and is rated at 35 microns"...

Still not crazy about needing to clean it and dispose of the solvent.

dpansier

Well Known Member

Although the above sounds great from a less-mess standpoint, it also means that at each start up the filter is empty and has to get re-filled before oil pressure starts to build. A big deal, probably not. Pretty sure the Tempest/Champions have check valves to prevent this.

I went back and reviewed my Savvy data to compare the oil pressure build time with the Tempest Filter and the K&P Filter, temperature and downtime between engine runs were similar.

The K&P that I have has no check valve.

Oil is Phillips 15W-50.

Data indicates little difference between the two filters.

Attachments

Last edited:

From their FAQ:

"The medical grade stainless steel cloth that we use is consistent across the entire media surface and is rated at 35 microns"...

Still not crazy about needing to clean it and dispose of the solvent.

I use much less solvent cleaning my K&P than I did rinsing my Champion after spending a lot of time opening the can, and cutting off the paper filter.

I dump the solvent in with the oil and dispose of it at the oil recycling point in my town.

Although the above sounds great from a less-mess standpoint, it also means that at each start up the filter is empty and has to get re-filled before oil pressure starts to build. A big deal, probably not. Pretty sure the Tempest/Champions have check valves to prevent this.

The check valve prevents oil from draining back down the pump passage when the vernatherm cools and opens. The goal is to keep the pump primed, not to keep the filter full. There is no check valve to block flow from the filter into the engine.

Walt

Well Known Member

The check valve prevents oil from draining back down the pump passage when the vernatherm cools and opens. The goal is to keep the pump primed, not to keep the filter full. There is no check valve to block flow from the filter into the engine.

From champion:

Modern spin-on oil filters contain the element, incorporating the anti-drain back valve mechanism (and internal bypass valve 48108-1/48109-1), and are sealed in a disposable housing.

Went down the rabbit hole and found some interesting info on the anti-drain back valve:

https://www.qaa.com/wp-content/uploads/tempest-oil-filter-valves.pdf

Brief summary:

https://www.qaa.com/wp-content/uploads/tempest-oil-filter-valves.pdf

Brief summary:

Attachments

Good info on ADB valves, the 45deg adapters all use the 48108 filters, with the ADB valve, so the takeaway may be that if you have a 45 deg adapter you should probably stick with ADB filter. Please correct me if I’m wrong.

Well, best I know, all the Champion and Tempest filters incorporate an anti-drainback valve.

48108 and 109 filters also have a pressure relief valve, because a lot of Continentals, and several popular filter adapters for Lycomings, don't have a built-in pressure relief in the adapter.

.

Two photos, AC style adapter standard on a Lyc. Built in pressure relief valve, so the correct filters (48110 or 111), don't have one in the filter.

Note lack of PRV in the Superior and right angle adapters. Use a 108 or 109. The PVR is a poppet valve in the element end cap.

.

Attachments

Anti drain back valve

Dan, are you referring to the rubber diaphragm top side to the 8 oil inlet holes on the bottom of the filter?

2 weeks ago I opened a CH 48110-1 (Champion) and there was no rubber diaphragm incorporated in this position.

Different topic.

Apart from the male/female bottom job, what is the difference between the 48110 and 48108?

Thanks

Dan, are you referring to the rubber diaphragm top side to the 8 oil inlet holes on the bottom of the filter?

2 weeks ago I opened a CH 48110-1 (Champion) and there was no rubber diaphragm incorporated in this position.

Different topic.

Apart from the male/female bottom job, what is the difference between the 48110 and 48108?

Thanks

I have the 45 degree adapter, and was concerned about the K&P not having an anti-drain-back (ADB) valve. What I see in my oil pressure graphs is the time for the oil pressure to buildup to 25psi, which I believe is considered the minimum, grew from roughly 3 seconds with the Champion to about 4 seconds with the K&P.

As Walt said, is this probably not a big deal.

As Walt said, is this probably not a big deal.

I have the 45 degree adapter, and was concerned about the K&P not having an anti-drain-back (ADB) valve. What I see in my oil pressure graphs is the time for the oil pressure to buildup to 25psi, which I believe is considered the minimum, grew from roughly 3 seconds with the Champion to about 4 seconds with the K&P.

As Walt said, is this probably not a big deal.

I guess the most realistic test would be to measure this time over a few hot-start scenarios as described (ie startup within 60 seconds of shutdown), as that is the scenario the ADB valve was meant to protect against. Personally, I can't imagine many times when I would be doing that in normal operation.

Chris

Why is drain back a concern after a quick turn around and not after a day, week, or longer?

Per Tempest, it is because the cooler (thicker) oil creates a better seal between the pump's gears and housing and allows it to rebuild pressure much quickly than with thinner (hot oil).

Chris

Dan, are you referring to the rubber diaphragm top side to the 8 oil inlet holes on the bottom of the filter?

2 weeks ago I opened a CH 48110-1 (Champion) and there was no rubber diaphragm incorporated in this position.

Yes, but thank you, I stand corrected. Not all have an anti-drainback valve, including the Tempest 110's I've been using with an AC-style adapter.

Different topic.

Apart from the male/female bottom job, what is the difference between the 48110 and 48108?

The 110 has no pressure relief valve. The 108 does have a PRV in the element end cap....and, apparently, an anti-drainback rubber ring.

BillL

Well Known Member

Yes, but thank you, I stand corrected. Not all have an anti-drainback valve, including the Tempest 110's I've been using with an AC-style adapter.

The 110 has no pressure relief valve. The 108 does have a PRV in the element end cap....and, apparently, an anti-drainback rubber ring.

The internal pressure bypass for the 108 has been said by Tempest to be 12-14 psi. Do we know the bypass pressure at which the Lycoming base opens (110)?

The reason asked is to get confirmation that the stainless filter will not collapse when the delta-P reaches bypass pressures. A protection measure.

Info for the experimenters: filter delta-p vs capacity is important to quantify and should be known for our application.

Yes, but thank you, I stand corrected. Not all have an anti-drainback valve, including the Tempest 110's I've been using with an AC-style adapter.

The 110 has no pressure relief valve. The 108 does have a PRV in the element end cap....and, apparently, an anti-drainback rubber ring.

So I have two engines with angle adapters, and two with straight back adapters….and the way I remember it is that the angle adapters use filters with the anti-drain back flapper (108), and the straight backs use filters without (110) - which is why punching a hole in the filters on the angle adapters does nothing to let the filter drain during an oil change, while you can punch a hole in the straight back filters and it will help them drain.

And you can’t mix them up because one comes with a “spud” on the filter, and the other doesn’t…..

Which is why, when folks (not Dan!) say “do this when you change your oil/filter” without identifying the type, simply spreads confusion and mis-information….

Paul

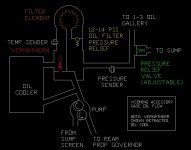

Does the oil to the oil cooler goes after it has gone thru the filter or it is from the pump to the oil cooler and then to the filter?

Oil cooler, then to the filter.

The internal pressure bypass for the 108 has been said by Tempest to be 12-14 psi. Do we know the bypass pressure at which the Lycoming base opens (110)?

My notes say 12~14, but I don't recall a Lycoming source for the information. Multiple non-OEM sources (Aviation Consumer, Tempest, etc) say the Lycoming adapter is in that ballpark. I think Donaldson makes the adapter for Lycoming, but I can't find specs at their site. Given all the STC'd non-bypass adapters out there for Lycoming, all of which would use 108/109 filter, I think we're pretty safe assuming the filter bypass delta is the same for all.

I did find this Tempest note on my hard drive. Worth a read. Here's a web link:

https://tempestplus.com/wp-content/uploads/2019/01/Alaska-Cold-Starts-0613.pdf

Does the oil to the oil cooler goes after it has gone thru the filter or it is from the pump to the oil cooler and then to the filter?

Only after the vernatherm has closed.

Only after the vernatherm has closed.

Actually, there is always some flow through the cooler. An extended vernatherm forces all of it through the cooler.

.

Attachments

Actually, there is always some flow through the cooler. An extended vernatherm forces all of it through the cooler.

.

Yes... I can see how that would be....

KelvinRempel

Member

PC Racing - PCS4C seems to be the equivalent of the S15, except it about $70 cheaper, has the nut and hole for safety wire and is available on Amazon. The specs are the same as the S15. Does anyone have any experience with this filter?

https://pcracingusa.com/shop/flo-oil/spin-on/harley-davidson-pcs4c-pcs4b/

https://pcracingusa.com/shop/flo-oil/spin-on/harley-davidson-pcs4c-pcs4b/

PC Racing - PCS4C seems to be the equivalent of the S15, except it about $70 cheaper, has the nut and hole for safety wire and is available on Amazon. The specs are the same as the S15. Does anyone have any experience with this filter?

https://pcracingusa.com/shop/flo-oil/spin-on/harley-davidson-pcs4c-pcs4b/

From the photos and the description it sure looks the same - either a clone or they got K&P to make the filters for them under a private label. Perhaps call them and ask who makes the filter?