Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shawn's -4 re-build

- Thread starter ShawnR

- Start date

throttle quad

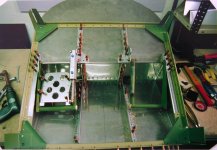

After a few days of messing around with my brake, practicing installing and removing rivets, dimpling, etc., (playing with the new tools) I am happy to report the quadrant is finally relocated. I needed time to over analyze it apparently, but, after drilling the first hole through the skin (s) (and into my hand, missing my backing block), the rest went well and with no more bandaids. I now need to put some supports in for the cover panels, cut the pass for the trim lever, etc but after thinking about this one little job for months, glad it is relocated. Proof I cannot build a kit from scratch! Not enough hours in a lifetime at the rate I work!

(and into my hand, missing my backing block), the rest went well and with no more bandaids. I now need to put some supports in for the cover panels, cut the pass for the trim lever, etc but after thinking about this one little job for months, glad it is relocated. Proof I cannot build a kit from scratch! Not enough hours in a lifetime at the rate I work!

After a few days of messing around with my brake, practicing installing and removing rivets, dimpling, etc., (playing with the new tools) I am happy to report the quadrant is finally relocated. I needed time to over analyze it apparently, but, after drilling the first hole through the skin (s)

Attachments

Last edited:

The first bend went well but in attempting the second bend, the lever snapped. I guess aluminum does not bend like steel, my usual material to work with. Oops. This morning, I went to the drawings to see what the lever is made of. It is 2024 x 0.125 which I don't have, but I should be able to find some, or weld it back together. I am aware of the concern for min bend radius for aluminum and don't think I was anywhere near exceeding that (but it appears I was wrong), but alas...live and learn.

Hi Shawn. I'm enjoying your thread since the 4 is my RV of interest. I dream of building one some day. Just thought I'd add a comment about the aluminum since we bend a lot of it here. The min. bend radius depends on the alloy. 2024 is one of the stronger, but also more brittle of the common alloys, so it needs a little larger radius.

Keep up the good work, and the updates. You're doing great.

Throttle quad and fuel valve

Thanks for the positive input and encouragement Luke!

I made some more progress on the quadrant relocate. I positioned and connected the throttle and mixture cables to check out alignment. Looks like it will work out nicely.

I have to admit, I am enjoying the project more and more, now that I am learning a bit. Not ready to order a kit yet though...

I picked up some poster board to use to lay out panels here and there. It looks like it will work well. It holds a crease. So the white panel shown is my first look at how to finish that panel off.

I figured the fuel valve was a little task that needed to be addressed so got it out today and took a look at it. It was very hard to turn, like, really hard. (previously posted about) After disassembling it, and scooping out the crud!!, , I decided to just replace it. So that makes that task easier.

I have seen the floor storage in some models and I think Van's has it in their optional plans. I saw it somewhere and it looks handy (tools, fuel sampler, etc. ) But, in my case, I will need to rebend or replace the aluminum fuel tubing to get it out of the way. I have the inputs for my fuel tank levels in my engine monitor, the EDM350 so I can remove the fuel gauges. This will clean up that area quite a bit.

I thought I had more photos to share but that is it. I still cannot figure out how to post them right side up. Maybe DadsRV10 can tell me the secret..?

Thanks for the positive input and encouragement Luke!

I made some more progress on the quadrant relocate. I positioned and connected the throttle and mixture cables to check out alignment. Looks like it will work out nicely.

I have to admit, I am enjoying the project more and more, now that I am learning a bit. Not ready to order a kit yet though...

I picked up some poster board to use to lay out panels here and there. It looks like it will work well. It holds a crease. So the white panel shown is my first look at how to finish that panel off.

I figured the fuel valve was a little task that needed to be addressed so got it out today and took a look at it. It was very hard to turn, like, really hard. (previously posted about) After disassembling it, and scooping out the crud!!, , I decided to just replace it. So that makes that task easier.

I have seen the floor storage in some models and I think Van's has it in their optional plans. I saw it somewhere and it looks handy (tools, fuel sampler, etc. ) But, in my case, I will need to rebend or replace the aluminum fuel tubing to get it out of the way. I have the inputs for my fuel tank levels in my engine monitor, the EDM350 so I can remove the fuel gauges. This will clean up that area quite a bit.

I thought I had more photos to share but that is it. I still cannot figure out how to post them right side up. Maybe DadsRV10 can tell me the secret..?

Attachments

Last edited:

To correct photos, the easiest way is to take them with phone turned in landscape position.

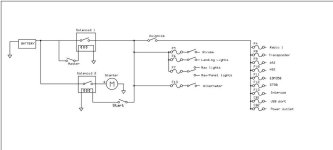

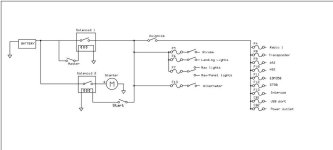

Looking at the schematic that you posted. You should switch the master ground instead of the hot side. No fuse needed.

The age of your gas valve (I would guess) it has a brass cone in it. A new one from Van's

will have a nylon cone and is an improved valve. You can clean and service them without

removing form the plumbing. Just unscrew the top. You should take your old valve and

reinstall the handle on the shaft and pull the cone out to see how it works. You can clean

and lube that valve, but if it is brass, I would buy a new one from Van's.

Looking at the schematic that you posted. You should switch the master ground instead of the hot side. No fuse needed.

The age of your gas valve (I would guess) it has a brass cone in it. A new one from Van's

will have a nylon cone and is an improved valve. You can clean and service them without

removing form the plumbing. Just unscrew the top. You should take your old valve and

reinstall the handle on the shaft and pull the cone out to see how it works. You can clean

and lube that valve, but if it is brass, I would buy a new one from Van's.

Last edited:

Roadjunkie1

Well Known Member

Throttle quadrant

I thought I posted these pictures before. A little late but your installation looks pretty good! I can see a bead blaster cleaning up that quadrant a little....

I knew it.........!!

Old tech but it works just fine.....

WHAT is that in the housing.........???

Keep on keeping on........!!

Thanks for the positive input and encouragement Luke!

I made some more progress on the quadrant relocate. I positioned and connected the throttle and mixture cables to check out alignment. Looks like it will work out nicely.

I thought I posted these pictures before. A little late but your installation looks pretty good! I can see a bead blaster cleaning up that quadrant a little....

I have to admit, I am enjoying the project more and more, now that I am learning a bit. Not ready to order a kit yet though...

I knew it.........!!

I picked up some poster board to use to lay out panels here and there. It looks like it will work well. It holds a crease. So the white panel shown is my first look at how to finish that panel off.

Old tech but it works just fine.....

I figured the fuel valve was a little task that needed to be addressed so got it out today and took a look at it. It was very hard to turn, like, really hard. (previously posted about) After disassembling it, and scooping out the crud!!, , I decided to just replace it. So that makes that task easier.

WHAT is that in the housing.........???

Keep on keeping on........!!

Attachments

Thanks Michael for the photos. Gives me some more ideas about how to attach the panels.

Yea, a thin mud is what seemed to come out of the valve. I was thinking that had I not bought a "fixer upper", I would probably not have jumped in so far, ie exploring, into the aircraft. Finding stuff like that is good, in that, I am glad I did not fly like that. Having said that, makes me wonder what the inside of the tanks look like and I am looking forward to pulling the gascolator apart! But it was probably cleaned each annual so it should be OK.

I have crawled down into the tail cone a couple of times, looking to see how it is all put together (both how and how well). Interesting.

Today, I pulled most of the wiring and electrical out. Found out that some of the switches are switch breakers. Nice find. Going to work on the switch panel next I think.

Just keep plugging along.

Yea, a thin mud is what seemed to come out of the valve. I was thinking that had I not bought a "fixer upper", I would probably not have jumped in so far, ie exploring, into the aircraft. Finding stuff like that is good, in that, I am glad I did not fly like that. Having said that, makes me wonder what the inside of the tanks look like and I am looking forward to pulling the gascolator apart! But it was probably cleaned each annual so it should be OK.

I have crawled down into the tail cone a couple of times, looking to see how it is all put together (both how and how well). Interesting.

Today, I pulled most of the wiring and electrical out. Found out that some of the switches are switch breakers. Nice find. Going to work on the switch panel next I think.

Just keep plugging along.

I was placing an order with Aircraft Spruce last night and ordered this valve

Would the one from Van's be different? They look the same. I still have time to cancel the valve if there is a difference.

Thanks for the input on the ground. That sounds familiar now that you mention it.

It's the same a Van's as long as you ordered the 4 port. Your original valve was plumed for a 180* turn from tank to tank and you must pass through a section of off. Plumb your new valve to switch in a 90* swing. The ports will be side by side with almost no dead spot between. In fact, I think one port opens before the other is fully closed.

Wrong valve

I ordered the 3 port. A/S says the 4 port is for 3 tanks.

I should be able to change it.

From the A/S description....

Indicating click on 3-port and 4-port valve (CN models) tells when handle is in full open or closed position. Tested to 30 PSI. Not FAA approved. *For 2 tanks. Flow is from either side to branch. **For 3 tanks. Flow is from any side to bottom outlet. Note: Order valve with 1/4" pipe threads for 3/8" dia. fuel line. Order valve with 3/8" pipe threads for 1/2" dia. fuel line. These pipe thread sizes are the ones normally associated with the indicated tube sizes.

* For 2 tanks. Flow is from either side to branch.

** For 3 tanks. Flow is from any side to bottom outlet.

Note: Order valve with 1/4" pipe threads for 3/8" dia. fuel line. Order valve with 3/8" pipe threads for 1/2" dia fuel line. These pipe thread sizes are the ones normally associated with the indicated tube sizes.

I will cancel it and wait till I order from Van's. Thank you for the heads up.

I ordered the 3 port. A/S says the 4 port is for 3 tanks.

I should be able to change it.

From the A/S description....

Indicating click on 3-port and 4-port valve (CN models) tells when handle is in full open or closed position. Tested to 30 PSI. Not FAA approved. *For 2 tanks. Flow is from either side to branch. **For 3 tanks. Flow is from any side to bottom outlet. Note: Order valve with 1/4" pipe threads for 3/8" dia. fuel line. Order valve with 3/8" pipe threads for 1/2" dia. fuel line. These pipe thread sizes are the ones normally associated with the indicated tube sizes.

* For 2 tanks. Flow is from either side to branch.

** For 3 tanks. Flow is from any side to bottom outlet.

Note: Order valve with 1/4" pipe threads for 3/8" dia. fuel line. Order valve with 3/8" pipe threads for 1/2" dia fuel line. These pipe thread sizes are the ones normally associated with the indicated tube sizes.

I will cancel it and wait till I order from Van's. Thank you for the heads up.

update and question

It has been quite a while since I updated. Progress has been slower than expected, which seems the norm.

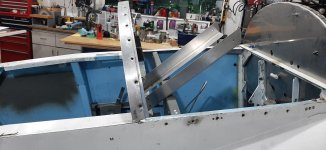

I did up the switch panel and covers on the right side. I went with 2 rockers for Master and Alternator, but toggles for the other switches. One is avionics and the other three are just lights. I decided to put the fuel pump switch next to the fuel pump valve. This seems to make sense to me versus mixed in the light switches. Not much else in the aircraft. Pretty basic.

I did more or less finish the quadrant area but need to reposition the trim cable to allow for the rear rudder pedals install. I bogged down on this. The trim cable was replaced by the seller. Not sure what the builder had in there. I see the routing is anything but straight and some bulkhead holes are in less than ideal locations. I am not sure if I should make new, central holes in an attempt to align and reposition the cable for my mod, or just leave the ones that I do not need to move as is. The damage is done, in my opinion so to make another hole in a bulkhead just so it looks better, in an area that is not at all visible..... Some holes do not have grommets so I will want to pull the cable out, enlarge the hole slightly and install a grommet. One in particular though is particularly close to the skin. That one might make more sense to either make a new hole, or use a clamp and go beside the bulkhead. I know not the norm, but save another hole in a bulkhead that already has a poorly located holes.

Some holes do not have grommets so I will want to pull the cable out, enlarge the hole slightly and install a grommet. One in particular though is particularly close to the skin. That one might make more sense to either make a new hole, or use a clamp and go beside the bulkhead. I know not the norm, but save another hole in a bulkhead that already has a poorly located holes.

Running out the door but thought I would throw this out there to get the think tank going....

It has been quite a while since I updated. Progress has been slower than expected, which seems the norm.

I did up the switch panel and covers on the right side. I went with 2 rockers for Master and Alternator, but toggles for the other switches. One is avionics and the other three are just lights. I decided to put the fuel pump switch next to the fuel pump valve. This seems to make sense to me versus mixed in the light switches. Not much else in the aircraft. Pretty basic.

I did more or less finish the quadrant area but need to reposition the trim cable to allow for the rear rudder pedals install. I bogged down on this. The trim cable was replaced by the seller. Not sure what the builder had in there. I see the routing is anything but straight and some bulkhead holes are in less than ideal locations. I am not sure if I should make new, central holes in an attempt to align and reposition the cable for my mod, or just leave the ones that I do not need to move as is. The damage is done, in my opinion so to make another hole in a bulkhead just so it looks better, in an area that is not at all visible.....

Running out the door but thought I would throw this out there to get the think tank going....

Attachments

Dad's RV-10

Well Known Member

Images rotated.

Thank you again

Roadjunkie1

Well Known Member

Progress.........

Nice progress! Yes, it always takes way longer than you think. Figure out how long a project will take, double that and it will take longer. I'm putting a splitter in for my EGT/CHF and just figuring out how everything plugs in is taking me forever.

You MIGHT consider making a cover of some sort for those cute little rocker switches as, if something hits them, you will lose power and wonder why. Just a thought....

Well, that cable routing is less than ideal. Since you are going to remove it anyway, I'd put it where it belongs. New holes with snap gromets would be an improvement. If you don't like the old holes, cover them up...

That looks like an extended baggage shelf which may not be the best idea in the world. That may be just a shelf for the ELT but pretty thick material there. Some RV-4s tend to be a little tail-heavy anyway and having baggage (if it is for that) WAY back there seems like not the best place to put it. Along with the weight of the shelf itself. Speaking of not the best, you have a pretty heavy ELT WAY back there as well. Is there a weight-and-balance issue that you NEED all that weight so far back? That might be better located as far forward on the baggage floor as possible. Mine is there and is never in the way. It also makes it MUCH more accessible if you need to take it out and carry it around with you......

Just some thoughts....

It has been quite a while since I updated. Progress has been slower than expected, which seems the norm.

I did up the switch panel and covers on the right side. I went with 2 rockers for Master and Alternator....

Nice progress! Yes, it always takes way longer than you think. Figure out how long a project will take, double that and it will take longer. I'm putting a splitter in for my EGT/CHF and just figuring out how everything plugs in is taking me forever.

You MIGHT consider making a cover of some sort for those cute little rocker switches as, if something hits them, you will lose power and wonder why. Just a thought....

I need to reposition the trim cable to allow for the rear rudder pedals install. I bogged down on this. The trim cable was replaced by the seller. Not sure what the builder had in there. I see the routing is anything but straight and some bulkhead holes are in less than ideal locations.

Well, that cable routing is less than ideal. Since you are going to remove it anyway, I'd put it where it belongs. New holes with snap gromets would be an improvement. If you don't like the old holes, cover them up...

That looks like an extended baggage shelf which may not be the best idea in the world. That may be just a shelf for the ELT but pretty thick material there. Some RV-4s tend to be a little tail-heavy anyway and having baggage (if it is for that) WAY back there seems like not the best place to put it. Along with the weight of the shelf itself. Speaking of not the best, you have a pretty heavy ELT WAY back there as well. Is there a weight-and-balance issue that you NEED all that weight so far back? That might be better located as far forward on the baggage floor as possible. Mine is there and is never in the way. It also makes it MUCH more accessible if you need to take it out and carry it around with you......

Just some thoughts....

Last edited:

You MIGHT consider making a cover of some sort for those cute little rocker switches as, if something hits them, you will lose power and wonder why. Just a thought....

I was toying with that too. Figured I would see how it goes ie get a feel for it when I start flying. I was concerned with toggles being next to the USB and Aux power ports, and them getting flipped accidentally. Also, as suggested here, make things safe if the situation gets a little hot, so I figured rockers are very different than toggles, so the feel would be different. Typing that now though, not sure what situation would become tense that would involve any of the switches. Maybe smoke from electronics so I would want to hit the avionics off quickly till I troubleshoot. I suppose hitting the master would solve the smoke issue, but cause others.....

Well, that cable routing is less than ideal. Since you are going to remove it anyway, I'd put it where it belongs. New holes with snap gromets would be an improvement. If you don't like the old holes, cover them up...

That looks like an extended baggage shelf which may not be the best idea in the world. That may be just a shelf for the ELT but pretty thick material there.

Just the ELT shelf. It is inaccessible usually. But with all of the changes I am making to the plane, I think a whole new W&B will be warrantied.

As for making new holes and installing bushings, then that is easy. I was just concerned about another hole, mostly in that one bulkhead where the cable is beside the skin. The hole is so far off of center. But, I suppose the side skin adds strength to the bulkhead as much as the bulkhead forms the skin.

fl-mike....I ordered those switches for a job many years ago and was surprised at their current rating for their size, but you raise a good point. I see they are rated for 9A at 120 volts but I cannot find a DC equivalent. I may need to search more. One only runs the Master solenoid so not much current on that. I don't know the current on the Alternator switch but had a 5 Amp fuse in mind on that circuit, so I figured they would be OK. I will dig a little deeper. The way I did that panel, it would be a minor issue if I had to replace the whole thing. And there is enough room to put in larger rockers, if I wanted to stay with that line of reasoning/thinking.

But, of course, one does not want to discover that need in the air. Thank you for the alert on it.

Attachments

Update

Still motoring along. I have the instrument panel cut, fitted and most holes cut for the instruments. In the old panel, the ELT panel was in a horizontal configuration (landscape?) but I want to install it vertical. Does anyone know if one can buy the stickers for the front? I am not opposed to installing it with the wrong sticker for now as I know I have seen them but can't come up with the correct google search words. I only find the whole panel.

As for the rest of the project, not sure what to report. It seems I am working on it but must be behind the scenes stuff. Removed brake lines and had stainless ones made up, ordered new snap bushings to reroute the trim cable mentioned earlier but waiting on those. Installed some cover plates in the bottom where old antennas were and had just been duct taped over. Cleaned up firewall (old grease, oil, crud. That was satisfying.... )

)

I do want to take it off of the landing gear next to sandblast and paint the legs and engine mount. It looks like if I mill a 2x6 down to 1 1/4" x 5", it will fit above the torque tube. I could then just rest this on short saw horses or tall axle stands. I figured on marking the board and then drilling it off the plane so as not to damage the holes for the wing spars but figured I would ask if anyone has suggestions here? Not much weight in the plane now with engine and wings off, canopy off, etc. But, as usual, I don't know what I don't know so very open to input.

I will post some panel photos shortly, once I have more to show.

Still motoring along. I have the instrument panel cut, fitted and most holes cut for the instruments. In the old panel, the ELT panel was in a horizontal configuration (landscape?) but I want to install it vertical. Does anyone know if one can buy the stickers for the front? I am not opposed to installing it with the wrong sticker for now as I know I have seen them but can't come up with the correct google search words. I only find the whole panel.

As for the rest of the project, not sure what to report. It seems I am working on it but must be behind the scenes stuff. Removed brake lines and had stainless ones made up, ordered new snap bushings to reroute the trim cable mentioned earlier but waiting on those. Installed some cover plates in the bottom where old antennas were and had just been duct taped over. Cleaned up firewall (old grease, oil, crud. That was satisfying....

I do want to take it off of the landing gear next to sandblast and paint the legs and engine mount. It looks like if I mill a 2x6 down to 1 1/4" x 5", it will fit above the torque tube. I could then just rest this on short saw horses or tall axle stands. I figured on marking the board and then drilling it off the plane so as not to damage the holes for the wing spars but figured I would ask if anyone has suggestions here? Not much weight in the plane now with engine and wings off, canopy off, etc. But, as usual, I don't know what I don't know so very open to input.

I will post some panel photos shortly, once I have more to show.

Last edited:

Panel

Test fitted the instruments in the panel. It is still a work in progress but good to see the instruments fit. I placed some a little too close, which made bracket installation tough, but it worked out ok. The one remaining spot is for a clock on order from Aircraft Spruce.

As mentioned earlier, the right spot was intentionally left clear so that occasional and temporary use of an ipad, phone, etc will not interfere with instruments. I am considering putting my fuse panel behind it and installing an access door in that spot.

Test fitted the instruments in the panel. It is still a work in progress but good to see the instruments fit. I placed some a little too close, which made bracket installation tough, but it worked out ok. The one remaining spot is for a clock on order from Aircraft Spruce.

As mentioned earlier, the right spot was intentionally left clear so that occasional and temporary use of an ipad, phone, etc will not interfere with instruments. I am considering putting my fuse panel behind it and installing an access door in that spot.

Attachments

Last edited:

Roadjunkie1

Well Known Member

Keep on keeping on.........

Nice! Good to get that panel where you are actually going to SEE it! Keep up the good work and letting us know....

Nice! Good to get that panel where you are actually going to SEE it! Keep up the good work and letting us know....

support for fuselage

As mentioned earlier, I need to take the gear and engine mount off. Someone had suggested a board through where the spar goes but looking at it today, will just a low platform centered on the wing spar bulkhead and the one ahead of it be enough? I am thinking a foam pad on a wide sawhorse. Like a small table....

With the engine off and not much else in there, there is not much weight on the two bulkheads that i will be sure to catch. I just want to sandblast, inspect and paint the gear and engine mount. Having said that, I would hate to wrinkle anything of course.

On another update, the engine guy let me know that all inspection items have come back from NDT and all good. I should see the engine around the end of the month. I am in no hurry for it yet, for sure. But nice to have the little fire simmering under my.....

As mentioned earlier, I need to take the gear and engine mount off. Someone had suggested a board through where the spar goes but looking at it today, will just a low platform centered on the wing spar bulkhead and the one ahead of it be enough? I am thinking a foam pad on a wide sawhorse. Like a small table....

With the engine off and not much else in there, there is not much weight on the two bulkheads that i will be sure to catch. I just want to sandblast, inspect and paint the gear and engine mount. Having said that, I would hate to wrinkle anything of course.

On another update, the engine guy let me know that all inspection items have come back from NDT and all good. I should see the engine around the end of the month. I am in no hurry for it yet, for sure. But nice to have the little fire simmering under my.....

Update

I have been working away on the project, despite the lack of updates here. The trim cable has been slightly moved and snap bushings installed through the bulkheads. New side panels from 2024 made to replace the mock up soffit material ones I had in place, brake cylinders removed, and cleaned up. I will be installing new pads, and discs.

I removed the engine mount and gear yesterday. Unfortunately, in addition to the wrinkles previously discussed, I found cracks in the firewall. I have found previous threads on this topic and the jest of them, of course, is further investigation to check the weldments, etc. I may be replacing the firewall. I have sent photos to Vans already for their input but suspect that they will tell me what we have heard before. Although the firewall is not considered structural, the cracks may be an indication of previous excessive stress. Will see what happens. This is as far as I have gotten so far. Well, more little stuff, but nothing exciting to report.

I have been working away on the project, despite the lack of updates here. The trim cable has been slightly moved and snap bushings installed through the bulkheads. New side panels from 2024 made to replace the mock up soffit material ones I had in place, brake cylinders removed, and cleaned up. I will be installing new pads, and discs.

I removed the engine mount and gear yesterday. Unfortunately, in addition to the wrinkles previously discussed, I found cracks in the firewall. I have found previous threads on this topic and the jest of them, of course, is further investigation to check the weldments, etc. I may be replacing the firewall. I have sent photos to Vans already for their input but suspect that they will tell me what we have heard before. Although the firewall is not considered structural, the cracks may be an indication of previous excessive stress. Will see what happens. This is as far as I have gotten so far. Well, more little stuff, but nothing exciting to report.

Attachments

Regarding the firewall, Van's has suggested just stop drilling the existing cracks. Another friend suggested the same and then of course sealing them up. How hard is it to change out the lower firewall, should I decide to go that way? It looks like most rivets are accessible at this point but don't know what I don't know....

I also found one gear leg bent slightly. I sent an email to Langair about with cross border shipping, etc., it may be better to straighten it here in Canada. Is this something any well equipped machine shop could do or is there more to it than just press it. I read in a thread here about a 20 ton press so that should be no problem in my area. We have some good industrial machine shops locally.

Anyone with input for me?

I also found one gear leg bent slightly. I sent an email to Langair about with cross border shipping, etc., it may be better to straighten it here in Canada. Is this something any well equipped machine shop could do or is there more to it than just press it. I read in a thread here about a 20 ton press so that should be no problem in my area. We have some good industrial machine shops locally.

Anyone with input for me?

Attachments

Stewbronco

Well Known Member

Fuselage support

Looks like you solved the “ sawhorse” option for supporting fuselage with motor mount and gear off ….any pictures of your solution ? Thanks

Looks like you solved the “ sawhorse” option for supporting fuselage with motor mount and gear off ….any pictures of your solution ? Thanks

Fuselage

Yes. I did not do the wood spar idea just because I do not want to mess with the spar bolt holes. I also wanted to keep the idea of mobility while being supported, should I need to move the project a bit. So I just made some platforms that I secured to my existing dolly and put foam under the bulkhead which the spar passes through. I tapered the foam a bit after finding it kind of wobbly against the contour of the belly. I will not be climbing in the plane like this. I had only planned on it being like this long enough to inspect and paint the mount and legs. Unfortunately, it might be longer than I had hoped. Sigh....

Yes. I did not do the wood spar idea just because I do not want to mess with the spar bolt holes. I also wanted to keep the idea of mobility while being supported, should I need to move the project a bit. So I just made some platforms that I secured to my existing dolly and put foam under the bulkhead which the spar passes through. I tapered the foam a bit after finding it kind of wobbly against the contour of the belly. I will not be climbing in the plane like this. I had only planned on it being like this long enough to inspect and paint the mount and legs. Unfortunately, it might be longer than I had hoped. Sigh....

Attachments

Dan 57

Well Known Member

Unfortunately, it might be longer than I had hoped. Sigh....

Hahaha, we warned you Shawn

Good job you're doing, she'll really be yours, and you'll be enjoying her immensely knowing that everything has been done properly.

Hahaha, we warned you ShawnAnd worse is to come as once you'll be done and flying that rejuvenated -4, you might realise now addicted to building or overhauling airplanes

Good job you're doing, she'll really be yours, and you'll be enjoying her immensely knowing that everything has been done properly.

Thanks Dan. I doubt I will become an overhaul enthusiast, but perhaps getting this project in the air will change that.

planenutz

Well Known Member

A couple of thoughts for you...

We had an RV-6 that landed heavily many years ago and the result was two bent legs (among other things). The owner replaced both legs and I can tell you it wasn't fun to try and re-drill those top bolt holes. It took me an age and more than one drill bit. The risk of getting the hole a bit off is also another detraction from installing a new one because I'd be pretty certain your legs will have been hand-drilled, not jig-drilled at the factory like they are today. No sooner had we got the aircraft flying for him and he went and did the same thing again, but this time he took the legs to a machine shop and had them straightened. That aircraft is still flying today, 30 years later, with those legs installed.

In respect to the firewall cracks, although its a lot more work for you I suspect that it would be easier to remove the firewall and take the opportunity to beef up some of the structure you would then have easy access to. Clearly if the leg is bent the aircraft has had a bit of punishment, but it seems to me that the RV-4 is a bit light in that area and could do with some upgrades. I suspect that if you pull that firewall out you will find some other bits in behind there that are also cracked and need attention. You've gone this far... you might as well go the whole hog!. Easy for me to say... I'm not the one who is in there doing it.

Easy for me to say... I'm not the one who is in there doing it.

Its going to be a great machine once you've got it back in the air. Good fun!

We had an RV-6 that landed heavily many years ago and the result was two bent legs (among other things). The owner replaced both legs and I can tell you it wasn't fun to try and re-drill those top bolt holes. It took me an age and more than one drill bit. The risk of getting the hole a bit off is also another detraction from installing a new one because I'd be pretty certain your legs will have been hand-drilled, not jig-drilled at the factory like they are today. No sooner had we got the aircraft flying for him and he went and did the same thing again, but this time he took the legs to a machine shop and had them straightened. That aircraft is still flying today, 30 years later, with those legs installed.

In respect to the firewall cracks, although its a lot more work for you I suspect that it would be easier to remove the firewall and take the opportunity to beef up some of the structure you would then have easy access to. Clearly if the leg is bent the aircraft has had a bit of punishment, but it seems to me that the RV-4 is a bit light in that area and could do with some upgrades. I suspect that if you pull that firewall out you will find some other bits in behind there that are also cracked and need attention. You've gone this far... you might as well go the whole hog!.

Its going to be a great machine once you've got it back in the air. Good fun!

Thanks Mike for the input. I was able to find a friend with a large press that has no problem deflecting the leg so we started straightening it yesterday. I had spoke with Langair beforehand about straightening it. If I was in the states, I would most likely have sent it to him, but the added costs and time to ship from Canada set me on the path to attempt it here. Mr Langair gave me some input on the process, which was helpful, and my associates are pretty good in the field, so I think we will be able to take the bow out of it. I will report back. We just ran out of time yesterday.

As for the firewall, I also heard back from Van's, about replacement, and they reiterated that for a non builder, such as myself, it is quite the task to replace the firewall. They are not encouraging it at all, which suggests to me that perhaps I should not get into that. I agree 100% with you, but may have to compromise with a very thorough inspection of the associated parts. I am going to look at the job again to decide.

As for the firewall, I also heard back from Van's, about replacement, and they reiterated that for a non builder, such as myself, it is quite the task to replace the firewall. They are not encouraging it at all, which suggests to me that perhaps I should not get into that. I agree 100% with you, but may have to compromise with a very thorough inspection of the associated parts. I am going to look at the job again to decide.

We were able to straighten the bent leg today. I would give it 90-95%...

It was certainly intimidating watching the counter bend (aka force) required to end up with an effect on the leg! I wish the press had a gauge on it but it did not. I always thought the legs looked "spindly" but seeing what it takes to take a bend out shows how strong they are! It also makes one wonder how the heck it got bent without doing more damage than previously discussed. Reinforces that I should and will be checking everything well....

My compressor has been down so I stripped the engine mount with a stripper which removed mostly, the paint only, but some primer. But, it did reveal the welds and so far, they all look good. The compressor is fixed so I can sandblast and start painting stuff, meaning reassembly is in the nearer future...

I am leaning towards not doing the firewall, but some more, indepth inspections are required before I commit one way or the other.

Thank you to all for the input.

It was certainly intimidating watching the counter bend (aka force) required to end up with an effect on the leg! I wish the press had a gauge on it but it did not. I always thought the legs looked "spindly" but seeing what it takes to take a bend out shows how strong they are! It also makes one wonder how the heck it got bent without doing more damage than previously discussed. Reinforces that I should and will be checking everything well....

My compressor has been down so I stripped the engine mount with a stripper which removed mostly, the paint only, but some primer. But, it did reveal the welds and so far, they all look good. The compressor is fixed so I can sandblast and start painting stuff, meaning reassembly is in the nearer future...

I am leaning towards not doing the firewall, but some more, indepth inspections are required before I commit one way or the other.

Thank you to all for the input.

Attachments

Last edited:

Stewbronco

Well Known Member

Sandblast

Be careful of the media you use to “ blast “ the mount ……less aggressive is better

Be careful of the media you use to “ blast “ the mount ……less aggressive is better

pr1malr8ge

Member

I have only ever used sand, Black diamond sand blast abrasive. Any suggestions for something else? The gear legs cleaned up nice with just sandpaper yesterday so will not be blasting those.

Look into soda blasting. this requires an entire new equipment, and make sure the air supply is moisture free.

If you don't want to buy new equipment then look into lower grit media for your sand blaster.. Walnut media or plastic.

Progress...?

Well, I think, thanks to a member who sent me a whole bunch of various weldment photos (old, new, modifications, etc) as well as other information, that I can rest a bit on my weldments concerns. He also pointed me to several links, and a google search by me, found more threads on this issue. Obviously, these weldments and the stess point there are a concern for RV4 flyers, and, since I already have a sign of some hard landings, (albeit the only sign is one bent leg) and I will be a new tailwheel flyer, off of a grass strip, I am hoping to make it idiot proof (if such a thing exists in flying...)

Here is what I have been struggling with (aka losing sleep).

After noting the bend in the right gear leg, I have gone over and over the weldments, looking for a crack or bends, etc. I said to myself yesterday that I was almost willing a crack into them! I cannot see anything. I think I will apply paint stripper to them to further check. But I also think that a break in the light blue paint could be more evident than a black crack in a black piece of steel. But....

My plane was first flown in 1985, and, I believe, if I understand correctly, that any mods to the weldments came well after that. A member in the past, here in this forum, did comment that "I have the new ones" but of course, with no note in the log book, I still denied it. (I may be a pessimist sometimes) But, with side by side photos, of the "old style" and "new style", I have decided that I do indeed have the "new style". I probably just have my timelines confused as to when they became available. Or repairs/changes were done and not documented. (Aside, annuals were often documented as "Annual complete", so documentation was not a huge part of the builders practice. The seller to me, however, did great entries! Now, to decide if they "need" the extra gusset plates added and/or if the piece of mind is worth it.....

The engine mount is out for magnaflux inspection. If it comes back good, then there is one wear spot I will address, and then start painting and reassembly. Woo Woo!

Well, I think, thanks to a member who sent me a whole bunch of various weldment photos (old, new, modifications, etc) as well as other information, that I can rest a bit on my weldments concerns. He also pointed me to several links, and a google search by me, found more threads on this issue. Obviously, these weldments and the stess point there are a concern for RV4 flyers, and, since I already have a sign of some hard landings, (albeit the only sign is one bent leg) and I will be a new tailwheel flyer, off of a grass strip, I am hoping to make it idiot proof (if such a thing exists in flying...)

Here is what I have been struggling with (aka losing sleep).

After noting the bend in the right gear leg, I have gone over and over the weldments, looking for a crack or bends, etc. I said to myself yesterday that I was almost willing a crack into them! I cannot see anything. I think I will apply paint stripper to them to further check. But I also think that a break in the light blue paint could be more evident than a black crack in a black piece of steel. But....

My plane was first flown in 1985, and, I believe, if I understand correctly, that any mods to the weldments came well after that. A member in the past, here in this forum, did comment that "I have the new ones" but of course, with no note in the log book, I still denied it. (I may be a pessimist sometimes) But, with side by side photos, of the "old style" and "new style", I have decided that I do indeed have the "new style". I probably just have my timelines confused as to when they became available. Or repairs/changes were done and not documented. (Aside, annuals were often documented as "Annual complete", so documentation was not a huge part of the builders practice. The seller to me, however, did great entries! Now, to decide if they "need" the extra gusset plates added and/or if the piece of mind is worth it.....

The engine mount is out for magnaflux inspection. If it comes back good, then there is one wear spot I will address, and then start painting and reassembly. Woo Woo!

Attachments

Dan 57

Well Known Member

I think your corner weldments are 2nd gen... just had a look at mine, kit #2062 delivered September 1988, and see that the lower corner is not one piece, but rather of a 2 tongues type.

Not sure, but I think to recall that material thickness was also increased.

Not sure, but I think to recall that material thickness was also increased.

Attachments

Thanks Dan

I heard/read there was an upgrade on thickness of material used. You also have the side gusset plates and it looks like another plate on the firewall side that I do not have.

I am thinking you built according to plans or did you add mods that you were made aware of at the time?

I heard/read there was an upgrade on thickness of material used. You also have the side gusset plates and it looks like another plate on the firewall side that I do not have.

I am thinking you built according to plans or did you add mods that you were made aware of at the time?

Dan 57

Well Known Member

Gotta admit I can’t remember for sure if those triangular pieces were in the plans, or mentioned in the RVator, or simply one of my mods… long time gone

Funnily enough I recall manufacturing them and bending the sides to match the longeron’s angle on them…

Maybe someone with a better memory chimes in?

Funnily enough I recall manufacturing them and bending the sides to match the longeron’s angle on them…

Maybe someone with a better memory chimes in?

I was just looking at the plans I have on hard drive and they show revisions up to 1996 but I see no mention of the larger gusset plates.

So, maybe the RVAtor....

Regardless, they seem to make sense and it is a good time to do it. I guess that is the next task.

Thanks

So, maybe the RVAtor....

Regardless, they seem to make sense and it is a good time to do it. I guess that is the next task.

Thanks

fixnflyguy

Well Known Member

Mid 90"s kit "new style"

While my RV-4 serial number is 2667, that was the early 90's tail. My fuselage kit was delivered around 1995, and I have the "new style" folded and welded longeron weldments. The original type had the split corners. The triangular gusset I have seen more than once, but don't believe it was ever in the kits, and I didn't install them on mine, and I payed attention to every Rviator I had..if I was building now, I'd probably put them in even if they are aluminum, as that lower corner takes a beating.

While my RV-4 serial number is 2667, that was the early 90's tail. My fuselage kit was delivered around 1995, and I have the "new style" folded and welded longeron weldments. The original type had the split corners. The triangular gusset I have seen more than once, but don't believe it was ever in the kits, and I didn't install them on mine, and I payed attention to every Rviator I had..if I was building now, I'd probably put them in even if they are aluminum, as that lower corner takes a beating.

Attachments

Dan 57

Well Known Member

Funny timing as I was just checking on my side if I could find something to add.

A lot of head scratching later, I found something:

A lot of head scratching later, I found something:

- 2 more pics, 1 showing the weldments before paint, the other one showing the reinforcement plate from the outside

- and the reference I found in the digital version of the RVator

Attachments

Last edited:

Update

At this point, I am shying away from making mods to the weldment areas. Upon inspection of them, they all look good so whatever repairs were done seem well done. In talking with others, some say do it, some say don't. But since Van's does not support the installation of extra support, I feel like it should not be required. A good idea yes, but not required. That may change as the project goes on.

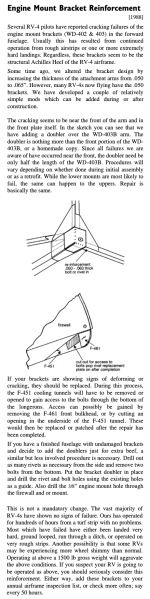

The engine mount was found to have a few slight cracks in it so it was sent for repair and more inspection. Waiting on that. While that was out, I was looking further at the bulkhead top piece behind the panel (F402C) It had been butchered and reinforced with smaller pieces of angles. I decided to fab a new one as per the plans. I had to dance around the previous rivet holes in the two vertical pieces for the new rivets, but feel better about the proper bulkhead in that location. I don't know how to calculate the strength of the pieces that made up the old one, but figured this one is better. You can see it in the photos below of the panel conflicts.

Until....that lead to conflicts with the panel which I designed not knowing that the bulkhead was incorrect or to be changed. I now have a conflict with my radio supports and the engine monitor. Good grief!

For the radio supports, it will simply be a matter of changing the location of the angle supports or making gusset plates instead of using angled pieces.

But the EDM350 rests up on the new bulkhead, and interferes directly with one of the connectors so this one needs more serious changes. My easy option is to interchange the engine monitor and one of the AV30's. Or, make a cover plate and change the configuration of the panel where the clock and EDM350 go. A third option of course is to install the EDM350 in that large area that I left clear so as not to interfere with a tablet. And fourthly, make a whole new panel....which ain't gonna happen...

What would you do?

At this point, I am shying away from making mods to the weldment areas. Upon inspection of them, they all look good so whatever repairs were done seem well done. In talking with others, some say do it, some say don't. But since Van's does not support the installation of extra support, I feel like it should not be required. A good idea yes, but not required. That may change as the project goes on.

The engine mount was found to have a few slight cracks in it so it was sent for repair and more inspection. Waiting on that. While that was out, I was looking further at the bulkhead top piece behind the panel (F402C) It had been butchered and reinforced with smaller pieces of angles. I decided to fab a new one as per the plans. I had to dance around the previous rivet holes in the two vertical pieces for the new rivets, but feel better about the proper bulkhead in that location. I don't know how to calculate the strength of the pieces that made up the old one, but figured this one is better. You can see it in the photos below of the panel conflicts.

Until....that lead to conflicts with the panel which I designed not knowing that the bulkhead was incorrect or to be changed. I now have a conflict with my radio supports and the engine monitor. Good grief!

For the radio supports, it will simply be a matter of changing the location of the angle supports or making gusset plates instead of using angled pieces.

But the EDM350 rests up on the new bulkhead, and interferes directly with one of the connectors so this one needs more serious changes. My easy option is to interchange the engine monitor and one of the AV30's. Or, make a cover plate and change the configuration of the panel where the clock and EDM350 go. A third option of course is to install the EDM350 in that large area that I left clear so as not to interfere with a tablet. And fourthly, make a whole new panel....which ain't gonna happen...

What would you do?

Attachments

Last edited:

Update

It has been a busy summer of house renovations so nothing done on the -4 project. As our building season is winding down, I am looking forward to getting back in the shop.

However, the engine rebuild was completed so I went to pick it up a couple weeks ago. Very happy with the looks and what he said he did. Can't wait to start it up! The engine mount was repaired and painted also since last posting.

Part of the house reno was to add a nice addition to my shop. This will be great to mount the engine and fit it all together in, sans wings.

I recall that the fuel pump had a conflict with the firewall at the shelf. In fact, I can see a small dent in the stainless where the front bend occurs so I will need to modify it so that it does not conflict again/still. I have seen images where guys have cut some away to accommodate the back of the engine with a constant speed prop. Anyone have any references for this? Unfortunately, it is very close to the angle brackets in the center. I have only just glanced at it so far. Will need to delve into it.

I think it will be another month or so till I can start posting progress photos. But thinking more and more about the project. Almost at the turning point where things start to go back together.

It has been a busy summer of house renovations so nothing done on the -4 project. As our building season is winding down, I am looking forward to getting back in the shop.

However, the engine rebuild was completed so I went to pick it up a couple weeks ago. Very happy with the looks and what he said he did. Can't wait to start it up! The engine mount was repaired and painted also since last posting.

Part of the house reno was to add a nice addition to my shop. This will be great to mount the engine and fit it all together in, sans wings.

I recall that the fuel pump had a conflict with the firewall at the shelf. In fact, I can see a small dent in the stainless where the front bend occurs so I will need to modify it so that it does not conflict again/still. I have seen images where guys have cut some away to accommodate the back of the engine with a constant speed prop. Anyone have any references for this? Unfortunately, it is very close to the angle brackets in the center. I have only just glanced at it so far. Will need to delve into it.

I think it will be another month or so till I can start posting progress photos. But thinking more and more about the project. Almost at the turning point where things start to go back together.

Attachments

fixnflyguy

Well Known Member

Thanks Bill! Can't say I deserve much credit for that. He asked me what colour I wanted and told him to go with the standard Lycoming colours. I was only picturing a grey case. The rest was the engine guy, but he has been doing these engines for 30 years, so ......

Did you do anything with the "shelf" on the firewall to accommodate the fuel pump fitting or was there a conflict there in your installation? My engine is an O360. It is just one fitting (I think, iirc, the fuel pressure outlet) that comes very close to the firewall. I will try to get some photos up today. Perhaps this is unique to the way the builder put the shelf in? I need to check some measurements probably. Another factor to consider, I had Barry mounts in before, and, now, will have Lord mounts. Not sure if that will change the spacing or not.

Did you do anything with the "shelf" on the firewall to accommodate the fuel pump fitting or was there a conflict there in your installation? My engine is an O360. It is just one fitting (I think, iirc, the fuel pressure outlet) that comes very close to the firewall. I will try to get some photos up today. Perhaps this is unique to the way the builder put the shelf in? I need to check some measurements probably. Another factor to consider, I had Barry mounts in before, and, now, will have Lord mounts. Not sure if that will change the spacing or not.

fixnflyguy

Well Known Member

What I did..and didnt

Shawn,

My engine is an O320H2AD, which typically has a fuel pump mounted on the front of the case..I didnt use it (requires a cowl bump), but use a dual electric pump system. Most RV-4's (O320/O360) require a "special" fuel pump vent fitting to prevent the contact into the firewall you are predicting. I don't have the P/N on hand, but others and even the build book list it. The center firewall recess is required in the firewall for a Prop Governor that would be driven off the accessory case. The plans book reflects the basic size for that if I recall, but I don't have a C/S prop, nor does my engine support a case driven governor. At your stage in the re-build, it would be prudent to add the recess. When I rebuilt my engine, I used Continental colors I had used for my A65 in my Taylorcraft because I liked the look..Deep Blue-gray case and gold cylinders..just never liked the plain Lyco all Grey factory colors. The engine mount choice shouldn't change the distance from the firewall or spinner.

Shawn,

My engine is an O320H2AD, which typically has a fuel pump mounted on the front of the case..I didnt use it (requires a cowl bump), but use a dual electric pump system. Most RV-4's (O320/O360) require a "special" fuel pump vent fitting to prevent the contact into the firewall you are predicting. I don't have the P/N on hand, but others and even the build book list it. The center firewall recess is required in the firewall for a Prop Governor that would be driven off the accessory case. The plans book reflects the basic size for that if I recall, but I don't have a C/S prop, nor does my engine support a case driven governor. At your stage in the re-build, it would be prudent to add the recess. When I rebuilt my engine, I used Continental colors I had used for my A65 in my Taylorcraft because I liked the look..Deep Blue-gray case and gold cylinders..just never liked the plain Lyco all Grey factory colors. The engine mount choice shouldn't change the distance from the firewall or spinner.

YellerDaisy

Well Known Member

The fuel pump overflow fitting that I think you are asking about is here. Part: F OVERFLOW PLUG 1/8"

Yes, the fit is VERY tight - especially if you follow Dan Horton's advice on firewall fireproofing. The contact spot is outside of the cutout/step for the prop governor. You can use the highly technical craft of metal shaping to get a wee bit of space (as in beat it with a hammer). You don't need much space there but obviously the motor does move around some - even that close to the motor mount rubbers.

Yes, the fit is VERY tight - especially if you follow Dan Horton's advice on firewall fireproofing. The contact spot is outside of the cutout/step for the prop governor. You can use the highly technical craft of metal shaping to get a wee bit of space (as in beat it with a hammer). You don't need much space there but obviously the motor does move around some - even that close to the motor mount rubbers.

Mmmmm...interesting. Thanks for the link to the fitting and the input. Glad I thought to ask before trying to mount the engine again. I will look into the options.

I see on plan #22 where it shows the cutout mod. But as Jon says, that mod ends on the inside of the angle pieces, and my pump seems to conflict on the outside of the angle pieces. At least, that is where the dent is in the firewall.

Thank you!

Cheers,

Shawn

I see on plan #22 where it shows the cutout mod. But as Jon says, that mod ends on the inside of the angle pieces, and my pump seems to conflict on the outside of the angle pieces. At least, that is where the dent is in the firewall.

Thank you!

Cheers,

Shawn

Last edited:

YellerDaisy

Well Known Member

You didn't ask but just in case... the plans for the firewall cutout for the prop governor are located on plans sheet #22 "F-401 & F-402 Bulkheads". Look closely at the drawings on the bottom right and the callout (starts with "CUTOUT FOR PROPELLER...").

It is not a difficult surgery but like all things, takes way more time than one might think. Some pics here. I made a lot of mistakes when doing mine. If I were doing it again, I would use only pulled rivets and I'd do the bending/tabs a bit differently. Attempting to drive rivets by myself in that very difficult space proved to be way over my capabilities.

It is not a difficult surgery but like all things, takes way more time than one might think. Some pics here. I made a lot of mistakes when doing mine. If I were doing it again, I would use only pulled rivets and I'd do the bending/tabs a bit differently. Attempting to drive rivets by myself in that very difficult space proved to be way over my capabilities.

![IMG-20230128-WA0001[1].jpg](/data/attachments/22/22500-38ee0b858dbd9c5d92cd4ea97a66fef0.jpg)