I put tire monitors on my airplane this week. First flight, three touch and goes, outside temp 84 degrees. Never used brakes on landings and taxied back to hangar, used brakes to stop. After about 2 minutes temperatures on the main gear tires was 104 on the left and 100.4 on the right. The PSI was up a little. Anyone else tried these monitors?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tire monitor

- Thread starter texdog

- Start date

dmattmul

Well Known Member

Whose monitors ?

Can you send a link? Most cap type monitors do not fit and if you have found ones that fit could be helpful. My Beringer monitors I routinely see temps 20 to 30 F over ambient after braking.

I put tire monitors on my airplane this week. First flight, three touch and goes, outside temp 84 degrees. Never used brakes on landings and taxied back to hangar, used brakes to stop. After about 2 minutes temperatures on the main gear tires was 104 on the left and 100.4 on the right. The PSI was up a little. Anyone else tried these monitors?

Can you send a link? Most cap type monitors do not fit and if you have found ones that fit could be helpful. My Beringer monitors I routinely see temps 20 to 30 F over ambient after braking.

Last edited:

rmarshall234

Well Known Member

Nitrogen

An interesting experiment would be to replace the shop air in the tires with Nitrogen and see how the rising temps change under similar conditions. I’ve found that N2 filled tires need *replenishing much less frequently. I’ve been told it’s bc N2 is a bigger molecule but can’t confirm that part.

An interesting experiment would be to replace the shop air in the tires with Nitrogen and see how the rising temps change under similar conditions. I’ve found that N2 filled tires need *replenishing much less frequently. I’ve been told it’s bc N2 is a bigger molecule but can’t confirm that part.

[email protected]

Well Known Member

A quick Google search will tell you that The nitrogen molecule is larger than the rest. But, our air is made up of 78 percent of nitrogen already. And most of the rest is oxygen with one percent other gases.

So it's a toss up as to if there is any benefit.

As they say " If you got it use it" But, I don't think it will make a very big difference.

Maybe, maybe not. It will make a small difference But will you even notice it?

My luck varies Fixit

So it's a toss up as to if there is any benefit.

As they say " If you got it use it" But, I don't think it will make a very big difference.

Maybe, maybe not. It will make a small difference But will you even notice it?

My luck varies Fixit

I've had people suggest putting Nitrogen in car tires for the same reason. Absolutely insisted it was a revolutionary idea. When I suggested that you can get the same result with air, and save on the cost of paying for a single gas, they were baffled. So, let me explain.

Air is about 80% Nitrogen.

Let's assume that every single non-Nitrogen molecule sneaks out of the rubber and only Nitrogen is left. From a starting point of 40psi, you would drop to 32. Refill the tire with air back to 40.

After topping it off, your tire is now 96% Nitrogen. (80% from the first fill plus 80% of the 20% you are topping off).

By the time you top your tires off a second time, you are north of 99%.

Paying someone to fill your tires with pure Nitrogen, assuming you have some way of vacuuming out all the air in the first place to get a pure fill, really isn't worth it.

Air is about 80% Nitrogen.

Let's assume that every single non-Nitrogen molecule sneaks out of the rubber and only Nitrogen is left. From a starting point of 40psi, you would drop to 32. Refill the tire with air back to 40.

After topping it off, your tire is now 96% Nitrogen. (80% from the first fill plus 80% of the 20% you are topping off).

By the time you top your tires off a second time, you are north of 99%.

Paying someone to fill your tires with pure Nitrogen, assuming you have some way of vacuuming out all the air in the first place to get a pure fill, really isn't worth it.

But, back to the original point - I think the pressure caps are a great idea. I recently saw an article about them in either the EAA or AOPA mag. Given how much work it takes to remove the fairings and check pressure, this would make life a lot easier.

I've found a couple of brands on Amazon - they look like knockoffs of each other - Leepee and Wistek. Probably made in the same factory in China.

Does anyone have any experience with these and the nosewheel forks for clearance?

I think there is no issue with putting these on the mains on an RV-10, but the standard yellow metal cap on the nosewheel just barely clears the fork on rotation. I can't tell on the Amazon page if these are any thicker than that - has anyone tried them? I figure that the worst case is I just buy a motorcycle pair for the mains and keep checking the nosewheel the old fashioned way.

I've found a couple of brands on Amazon - they look like knockoffs of each other - Leepee and Wistek. Probably made in the same factory in China.

Does anyone have any experience with these and the nosewheel forks for clearance?

I think there is no issue with putting these on the mains on an RV-10, but the standard yellow metal cap on the nosewheel just barely clears the fork on rotation. I can't tell on the Amazon page if these are any thicker than that - has anyone tried them? I figure that the worst case is I just buy a motorcycle pair for the mains and keep checking the nosewheel the old fashioned way.

LeePee

I read the AOPA article and decided to try them. They fit, but just barely, they touch the rim on the axle. They rotate with the axle, so they should not come lose. I think they are on all the time. I didn’t check if I got a reading in the air, but I got a warning on the temperature two minutes after I exited the cockpit. I left them on for two days to see if I lost air before I put the wheel pants on. We need more time on them. I think it would be a big improvement over TLAR

I read the AOPA article and decided to try them. They fit, but just barely, they touch the rim on the axle. They rotate with the axle, so they should not come lose. I think they are on all the time. I didn’t check if I got a reading in the air, but I got a warning on the temperature two minutes after I exited the cockpit. I left them on for two days to see if I lost air before I put the wheel pants on. We need more time on them. I think it would be a big improvement over TLAR

Unless you have just aborted a takeoff at max weight just below V1 in a large aircraft, what's the point?

What's the point of a tire pressure monitor? With the RV-10 (probably others, but I only know the -10), checking each tire pressure is about a 15-20 minute exercise, not to mention stripped screw heads and other fun. Checking pressure on a display would save a lot of time versus a wheel-pants-off check. And it would let you know for sure before every flight, versus just eyeballing a flat.

MacCool

Well Known Member

What's the point of a tire pressure monitor? With the RV-10 (probably others, but I only know the -10), checking each tire pressure is about a 15-20 minute exercise, not to mention stripped screw heads and other fun.

I would be concerned about the TPMS unit's allowing an air leak. On my -9A, I have a 1 inch hole directly in line with where the valve stem can be rotated to. With a socket/extension to remove the valve stem cap and a straight air chuck on the compressor, I can check the pressures and air the tires up in a few minutes, and no screwdriver required. I always start by a careful look at the tires first, just to make sure that even that effort is necessary.

I note that Cirrus and some other airplanes have a little door on the wheel pants providing even more convenient access. That would be cool, but more fiberglass fabrication effort than I'd want to undertake.

..

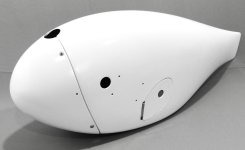

Attachments

Saber25

Well Known Member

I thought the original op was for tire temperature. Perhaps I misread. I have a small rectangular access cover for the RV4 I made decades ago through which I can access the tube stem for pressure and filling. The Pitts and Laser are simply using a round metal button that fits snugly into the wheel pant. I believe they are available at your Home Depot aircraft supply aisle. The only time I take the pants off is to change rubber or grease the bearings.

Air

I have no leak tubes, but they still leak a little. I have a hole with a button to cover it up on the wheel pants. It has worked great for 11 years. I like the idea of knowing where the pressures are. No shimmy if the air pressures are correct. The temperature probably doesn’t matter that much. I’ve tried to guess the pressure for years and I can’t guess within 5 lbs. consequently shimmy on takeoff for a long trip and get air at first stop. We cover a lot of miles away from home in our airplane. If this works I believe it will be a comfort factor.

I have no leak tubes, but they still leak a little. I have a hole with a button to cover it up on the wheel pants. It has worked great for 11 years. I like the idea of knowing where the pressures are. No shimmy if the air pressures are correct. The temperature probably doesn’t matter that much. I’ve tried to guess the pressure for years and I can’t guess within 5 lbs. consequently shimmy on takeoff for a long trip and get air at first stop. We cover a lot of miles away from home in our airplane. If this works I believe it will be a comfort factor.

Pilot135pd

Well Known Member

I don't understand why some ask why he did it. Some people like to add additional things to their planes that to others think aren't needed. Some choose paint others choose wrap. He added a tire temp, good for him and his plane. With temps here around 107 today, I'd like to know what my tire temps are just for the heck of it.

Bill Boyd

Well Known Member

What's the point of a tire pressure monitor? With the RV-10 (probably others, but I only know the -10), checking each tire pressure is about a 15-20 minute exercise, not to mention stripped screw heads and other fun. Checking pressure on a display would save a lot of time versus a wheel-pants-off check. And it would let you know for sure before every flight, versus just eyeballing a flat.

I clocked myself Saturday: checking/airing the mains on the -10, which I need to do more often than I'd like even with Air-Stop tubes, took me 4 minutes start to finish. Would have been half that if I had properly marked the mains to allow rapid location of the stem in the wheel pant hole. Not a particularly odious task IMO.

dmattmul

Well Known Member

Pics please !!

Bill, would love to see pics of your set-up and 4 minute (or less) process. Most I've seen look rather crude. (Large holes in the side of your wheel pant, who knows how that effects drag).

Thanks !

I clocked myself Saturday: checking/airing the mains on the -10, which I need to do more often than I'd like even with Air-Stop tubes, took me 4 minutes start to finish. Would have been half that if I had properly marked the mains to allow rapid location of the stem in the wheel pant hole. Not a particularly odious task IMO.

Bill, would love to see pics of your set-up and 4 minute (or less) process. Most I've seen look rather crude. (Large holes in the side of your wheel pant, who knows how that effects drag).

Thanks !

Last edited:

bruceh

Well Known Member

I've had people suggest putting Nitrogen in car tires for the same reason. Absolutely insisted it was a revolutionary idea. When I suggested that you can get the same result with air, and save on the cost of paying for a single gas, they were baffled. So, let me explain.

Air is about 80% Nitrogen.

Let's assume that every single non-Nitrogen molecule sneaks out of the rubber and only Nitrogen is left. From a starting point of 40psi, you would drop to 32. Refill the tire with air back to 40.

After topping it off, your tire is now 96% Nitrogen. (80% from the first fill plus 80% of the 20% you are topping off).

By the time you top your tires off a second time, you are north of 99%.

Paying someone to fill your tires with pure Nitrogen, assuming you have some way of vacuuming out all the air in the first place to get a pure fill, really isn't worth it.

The assumption here is that the air is "dry" of any moisture, aka H2O.

The Hydrogen molecule in water makes it less dense than dry air.

Using Nitrogen from a tank gives you absolutely no moisture in the tire tube.

Bill Boyd

Well Known Member

Bill, would love to see pics of your set-up and 4 minute (or less) process. Most I've seen look rather crude. (Large holes in the side of your wheel pant, who knows how that effects drag).

Thanks !

"Large holes in the side" is exactly right. They make snap plugs for them that can be painted to match, and I did that for my 6A but never bothered with the 10. Maybe I'll gain a knot if I install them. And another if I transport my tie down rings inside the plane instead of under the wings. Sloppy habits.

Using the side hole method and a push-on air chuck does require an extra, strategically located hole in the nosewheel fork but no extra modding of the main pants except the one hole in the side the correct distance from the axle axis.

The time saved in airing the tires more than offsets the cruise speed reduction

MacCool

Well Known Member

Bill, would love to see pics of your set-up and 4 minute (or less) process. Most I've seen look rather crude. (Large holes in the side of your wheel pant, who knows how that effects drag).

Thanks !

The snap plug from my local hardware store. I didn't bother to paint them.

..

Attachments

Bill Boyd

Well Known Member

pictures located

Shows holes in nose pant for valve stem and Bogert bar access, and in right main for valve stem.

Maybe one day I will bother to close them up with plugs, but I doubt it. Plane cruises at 160 KTAS on 11.3 mph and I'm content with that for now.

Like I said, filling the mains takes under 5 minutes even if you have to take pains with a flashlight to locate the valve stems - a process I could streamline with proper markings on the outside of the tires, as discussed on VAF many times.

For some reason, the nose wheel tire seems to hold air forever... but it's still equally quick to service if needed via the provided hole.

ETA: kind of embarrassed to see this on the front page of tomorrow's edition - now everyone is going to see up close how I did with the turbine spray gun and Stewart waterborne paints on my own after the painter left. Definitely need to put wheel pant cut and buff on the long term punch list! Honestly, the rest of the plane didn't come out much better - and the cut and buff for the airframe was long and involved.

Shows holes in nose pant for valve stem and Bogert bar access, and in right main for valve stem.

Maybe one day I will bother to close them up with plugs, but I doubt it. Plane cruises at 160 KTAS on 11.3 mph and I'm content with that for now.

Like I said, filling the mains takes under 5 minutes even if you have to take pains with a flashlight to locate the valve stems - a process I could streamline with proper markings on the outside of the tires, as discussed on VAF many times.

For some reason, the nose wheel tire seems to hold air forever... but it's still equally quick to service if needed via the provided hole.

ETA: kind of embarrassed to see this on the front page of tomorrow's edition - now everyone is going to see up close how I did with the turbine spray gun and Stewart waterborne paints on my own after the painter left. Definitely need to put wheel pant cut and buff on the long term punch list! Honestly, the rest of the plane didn't come out much better - and the cut and buff for the airframe was long and involved.

Attachments

Last edited:

Plus one .....I don't understand why some ask why he did it. Some people like to add additional things to their planes that to others think aren't needed. Some choose paint others choose wrap. He added a tire temp, good for him and his plane. With temps here around 107 today, I'd like to know what my tire temps are just for the heck of it.

The assumption here is that the air is "dry" of any moisture, aka H2O.

The Hydrogen molecule in water makes it less dense than dry air.

Using Nitrogen from a tank gives you absolutely no moisture in the tire tube.

True - except that 1, a compressor typically dehumidifies the air, hence the need for a moisture trap or a manual drain on the tank. 2, I live in Colorado, where humidity has generally been outlawed.

Which monitors did you use? Any issues fitting under the wheel pants?I put tire monitors on my airplane this week. First flight, three touch and goes, outside temp 84 degrees. Never used brakes on landings and taxied back to hangar, used brakes to stop. After about 2 minutes temperatures on the main gear tires was 104 on the left and 100.4 on the right. The PSI was up a little. Anyone else tried these monitors?

dmattmul

Well Known Member

Tool to add the cap.

Thanks, are you able to reach in and spin on and off the valve stem cap? If so what tool is used ? I guess one could make one as required.

The snap plug from my local hardware store. I didn't bother to paint them.

..

Thanks, are you able to reach in and spin on and off the valve stem cap? If so what tool is used ? I guess one could make one as required.

Dan 57

Well Known Member

There are different tire valve extensions available on the market, such as this one https://www.aircraftspruce.com/catalog/lgpages/ae06-03064.php or rigid ones...

I have drawn a mark on my tires that aligns with to the perpendicular of the bottom of the wheelpant, aligned and the valve cap faces the access hole.

Easy game then to remove the cap, install the extension, and pump air.

I have drawn a mark on my tires that aligns with to the perpendicular of the bottom of the wheelpant, aligned and the valve cap faces the access hole.

Easy game then to remove the cap, install the extension, and pump air.

Different needs

I have had both knees replaced and it isn’t as easy to jump up and down to do this job like I could before. The monitors are working great right now. If I hadn’t played bad sports for the knees I would’ve have kept airing them up the old way. It is nice to see PSI as soon as I get in the hangar. I’m only 3 or 4 PSI away from shimmy at 21 kts. on landing.

I have had both knees replaced and it isn’t as easy to jump up and down to do this job like I could before. The monitors are working great right now. If I hadn’t played bad sports for the knees I would’ve have kept airing them up the old way. It is nice to see PSI as soon as I get in the hangar. I’m only 3 or 4 PSI away from shimmy at 21 kts. on landing.

Mikeyb

Well Known Member

I think it is a great idea. The Matco brakes on an RV8 are almost at their energy dissipation limit after one full stop landing. Considering people’s experience with brake fires having information about what the temperature is inside the wheel pants seems desirable in addition to keeping your tires at optimum pressure.

https://vansairforce.net/community/showthread.php?t=32917

https://vansairforce.net/community/showthread.php?t=32917

FWIW, the Recreational Vehicle RV people tend to dislike these valve cap TPMS systems because they require the actual tire valve to be open all of the time and a failure of the TPMS cap would result in a rapid deflation.

It isn't clear whether this has actually happened.

It isn't clear whether this has actually happened.

Bill Boyd

Well Known Member

To people filling air through the little opening on the wheel pants, can I ask how you fix the air hose to the stem? Thanks.

Push straight on. If needed, add a stiffener sleeve to the air chuck hose.

Last air chuck I grabbed didn't seal well to the stem and the tire went almost flat while I was trying to force air in. Quick change to another unit (from Harbor Freight of all places) saved the day.

I don't "do" valve caps anymore but understand the risks of dirt contamination - a trade-off like everything else.

Tailwind/RVGuy

Active Member

I used this extension. Screwed two of them together with a little red loctite. Works great. Line up the stem to the hole in my wheel pant, use a nut driver to take off the valve core cap and then screw on this extension to check or fill. I also carry a very small 12 volt compressor which has "saved my bacon" a few times.

https://www.amazon.com/AUTOHAUX-Scr...92703583&sprefix=tire+valve+ex,aps,165&sr=8-4

https://www.amazon.com/Slime-40059-...olt+air+compressor&qid=1692703052&sr=8-9&th=1

The above compressor has a push on connector. The one that I actually use is similar but has a screw on connector which works better than the one shown.

https://www.amazon.com/AUTOHAUX-Scr...92703583&sprefix=tire+valve+ex,aps,165&sr=8-4

https://www.amazon.com/Slime-40059-...olt+air+compressor&qid=1692703052&sr=8-9&th=1

The above compressor has a push on connector. The one that I actually use is similar but has a screw on connector which works better than the one shown.

Last edited:

MacCool

Well Known Member

Thanks, are you able to reach in and spin on and off the valve stem cap? If so what tool is used ? I guess one could make one as required.

I use a Jonard double-ended socket that the previous owner had included in the tool kit when he sold me the plane, or a 3/8 socket on an extension if I can't find the other thing.

To people filling air through the little opening on the wheel pants, can I ask how you fix the air hose to the stem? Thanks.

I use an inflator, but with a straight air chuck. Takes two hands. I could probably use one of those self-retaining chucks but haven't ever needed to.

The the only issue with this method is getting the valve aligned with the hole the wheel pants. Easy to do if you have another person to move the plane back and forth to get them aligned, but if you're by yourself you have to move the plane while you're on the ground. Airplanes move easier on some surfaces than others. It hasn't usually been an issue for me, but if the tire's low and the plane doesn't move easily, I can slip a wing jack (or a human) under the wing and lift it enough to rotate the tire easily. That's pretty easy but I've only had to do that once.

...

Attachments

Bill Boyd

Well Known Member

On the ground, my planes have only seemed to move easily when I didn't want them to.

The more nimble 6A was understandably worse in this regard, but the 10 will sometimes move a bit on it's own if there's a flat spot on a tire from sitting, or a low spot in the hangar floor. This tendency to seek to roll back to wherever you forcibly moved it from to align the valve stem in the hole makes me shy away from screw-on extensions on the stem - you can put a lot of side force on the rubber stem if the extension hits the edge of the hole and the plane is still tying to move further, and that's a handful if you are working alone.

The more nimble 6A was understandably worse in this regard, but the 10 will sometimes move a bit on it's own if there's a flat spot on a tire from sitting, or a low spot in the hangar floor. This tendency to seek to roll back to wherever you forcibly moved it from to align the valve stem in the hole makes me shy away from screw-on extensions on the stem - you can put a lot of side force on the rubber stem if the extension hits the edge of the hole and the plane is still tying to move further, and that's a handful if you are working alone.

The the only issue with this method is getting the valve aligned with the hole the wheel pants. Easy to do if you have another person to move the plane back and forth to get them aligned, but if you're by yourself you have to move the plane while you're on the ground.

Once you have the hole and the valve stem aligned, put a dot of white paint on the tire at the 6 o’clock position. You can see it’s aligned before getting on the ground.

MacCool

Well Known Member

Once you have the hole and the valve stem aligned, put a dot of white paint on the tire at the 6 o’clock position. You can see it’s aligned before getting on the ground.

It's never been a practical problem, more of an annoyance, but that's a great tip and I'm a little embarrassed that I've never thought of that.

To people filling air through the little opening on the wheel pants, can I ask how you fix the air hose to the stem? Thanks.

Auto Parts store, look for valve stem extensions for dual wheels. 4pack of 3" are around $10 here in Alaska. These barely stick out of the pants on my 6. One option is to piggyback onto each other as needed for length, however

4" are better but I ordered a 6" that makes it super easy to fill.

They screw directly onto the original valve stem, just hook a pump up and fill as needed.

https://www.napaonline.com/en/p/NTH90304B?ir=3&r-src=FBT:PDP&ppid=NTH90329

Mike

Last edited:

Thanks, are you able to reach in and spin on and off the valve stem cap? If so what tool is used ? I guess one could make one as required.

Hand driven nut driver. Hex cap can be bought at auto part stores for the valve stem.

Mike

We flew two RV6As from Fredericksburg to Carson City and back, 2300 nautical miles. Two flats, I don’t think they were caused by the tire pressure monitors, but bad karma. I took them off today. One was caused by a valve stem extension that bent the valve stem. It didn’t go flat, but loss of half of the air. Mine was a sidewall pin hole leak in the Leak Guard tube. Mine was in Big Spring, Tx. I was lucky the FBO had a main tire and tube. In Carson City the maintenance facility said 30 days we will look at it. I had a new tube and a tailgate mechanic changed the tire and tube. Thank you Jess. Overall good trip, 146 nautical miles per hour, head winds most of the way.