So, current status:

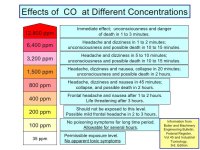

@ravenstar yup, tracking all. Got myself much more educated on CO, watched some good videos and think I have at least a more than rudimentary understanding at this point. Thanks for the key point.

@rv8ch

Thanks - actually did in fact get after some of your points.

Just completed my first oil change, with some help, and did as much CO troubleshooting as I could. Talked to Clint at Vetterman and got some good intel from him as well. He confirmed that the joints are not air tight, and in fact, cannot be as the exhaust system needs the flex relief to survive engine vibration. A fully welded set of pipes would crack or shatter. Bottom line - some CO will absolutely be in the engine compartment forward of the firewall.

- Installed Flightline Interiors aileron push rod boots. Wanted to mitigate some of the airflow anyway, and they were inexpensive at $53 and easy to install. Abby was very nice and had plenty of info to help.

- Had an RTV party in my tail, trying to seal up obvious gaps on the bottom. Tail wheel spring outlet, the tail wheel spring through-bolt head, etc...

- RTV a few select spots where (a very, very little) light filtered through my firewall. Basically one nut plate and some micro thin gaps along the join with the fuselage skin.

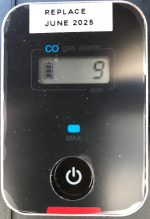

- Bought another CO monitor from Amazon (could buy six of the one I got for one of the Aithre ones) so I can validate / compare samplings.

- Plane actually had some no-kidding duct tape on the bottom, covering about two feet of the weather strip between the wingroot and the fuselage. I pulled the duct tape off, and redid it with.... Gorilla tape. Still cheap looking, but its on the bottom and I wanted to see if it helped mitigate the problem.

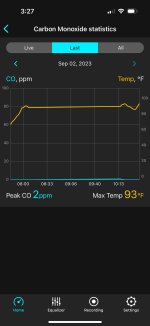

Took the plane today to a nearby airport for pitot-static / transponder IFR cert. Forgot to fire up the second CO monitor enroute, but my DZ headset said the CO peaked at 7ppm. More than I'd like, but way better than 90. On the way home, both the DZ and the Amazon version read zero. Not sure whether this is just condition of flight. I was at 2500, full rich and the flight was only about 20 minutes if that each way. But its still an improvement.

Next steps - I intend to keep monitoring, and keep sealing. Clint at Vetterman suggested that more air comes in from the flap rod holes than through the wings, so they are next. He suggested using a couple pieces of engine baffle, slit for the rod to travel and then RTV'ed to the inside of the fuselage skin. If i do that, I'll post pix. Clint also offered up a couple of exhaust downturners, which he guarantees will fix the problem (assuming it isn't coming in the firewall) but at the potential cost of a fraction of performance. Last thing I may try is to find some decent clear or neutral colored weather strip that would work on the bottom inside side edges of my sliding canopy.