Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Servo range of motion limiting bracket

- Thread starter jcbarker

- Start date

mc607

Well Known Member

jcbarker

Well Known Member

Walt

Well Known Member

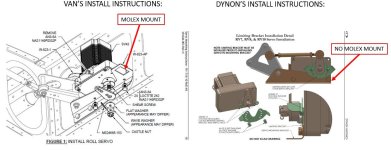

Personally, I'd replace the bracket and go with the Dynon instructions then cut off the Molex and replace with a standard DB15 connector.

Molex connectors are ok for lights and misc. stuff that doesn't really matter, but not ok for low level or data bus signals.

Be prepared for lots of mystery problems on the 14 due to the wide use of Molex connectors.

Molex connectors are ok for lights and misc. stuff that doesn't really matter, but not ok for low level or data bus signals.

Be prepared for lots of mystery problems on the 14 due to the wide use of Molex connectors.

Walt

Well Known Member

Hmm, really? Dynon and Stein seem to be ok with Molex. Used them on my -8 without any issues.

Van's sets the spec for the harnesses that Stein builds for them.

Dynon doesn't care, not their problem (pretty sure all 'Dynon" harnesses use DB connectors).

I love the RV aircraft, but when it comes to accessories Van's doesn't aways spec the best parts, more about saving $$.

I promise not to say 'I told you so'

Tankerpilot75

Well Known Member

I again agree with Walt. I’ve used both Molex and DB connectors on my aircraft. Have several issues in the past with Molex connectors not holding up as expected causing hours of trouble shooting to identify the problem.

ian greenland

Member

Limits

Your Airleron limits are you primary travell stops, check your instructions as to wether the servo stops before Airleron stops or after. This maybe before it hits the molex.

Your Airleron limits are you primary travell stops, check your instructions as to wether the servo stops before Airleron stops or after. This maybe before it hits the molex.

Walt

Well Known Member

Take a look at this old thread and then tell me you don't think servo stop are important!!!!!

https://vansairforce.net/community/showthread.php?t=112807

https://vansairforce.net/community/showthread.php?t=112807

Last edited:

dmattmul

Well Known Member

Molex connectors

Walt has probably already seen his fair share of the connectors giving "isolated and hard to track" issues. I did not use most of the "holding brackets" as it seemed to overcomplicate a "delicate" design. After talking to Vans management at several OSH events my guess is the 15 will not use these. The elevator trim Molex connector mounted in the vertical stab has been nothing but trouble for me. Several flying RV-14's builders have had to replace these which I also did 6 months ago. If you use these ensure the pins are inserted absolutely correct plus or minus a few degrees. It does not take much to have the pin slip back as the other pin is inserted and test each pin that the opposing male/female pin does not push it back. My elevator trim Molex connector would stop working in flight every 3 or 4 months after I plugged it in to start working again on the ground. Very frustrating.

Personally, I'd replace the bracket and go with the Dynon instructions then cut off the Molex and replace with a standard DB15 connector.

Molex connectors are ok for lights and misc. stuff that doesn't really matter, but not ok for low level or data bus signals.

Be prepared for lots of mystery problems on the 14 due to the wide use of Molex connectors.

Walt has probably already seen his fair share of the connectors giving "isolated and hard to track" issues. I did not use most of the "holding brackets" as it seemed to overcomplicate a "delicate" design. After talking to Vans management at several OSH events my guess is the 15 will not use these. The elevator trim Molex connector mounted in the vertical stab has been nothing but trouble for me. Several flying RV-14's builders have had to replace these which I also did 6 months ago. If you use these ensure the pins are inserted absolutely correct plus or minus a few degrees. It does not take much to have the pin slip back as the other pin is inserted and test each pin that the opposing male/female pin does not push it back. My elevator trim Molex connector would stop working in flight every 3 or 4 months after I plugged it in to start working again on the ground. Very frustrating.

mc607

Well Known Member

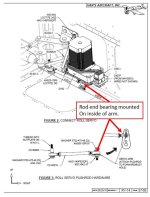

More threads regarding over centre. This topic has been a very valuable lesson. Note the rod end bearing was installed on the wrong side of servo arm in the first thread, according to Van’s Garmin KAI.

https://vansairforce.net/community/showthread.php?t=194434&highlight=Roll+servo

https://vansairforce.net/community/showthread.php?t=199862&highlight=Servo+Center

https://vansairforce.net/community/showthread.php?t=194434&highlight=Roll+servo

https://vansairforce.net/community/showthread.php?t=199862&highlight=Servo+Center

Last edited:

Take a look at this old thread and then tell me you don't think servo stop are important!!!!!

https://vansairforce.net/community/showthread.php?t=112807

Is it a valid argument to install a safety related part for an issue that was caused by a flagrant construction error? (Pretty sure this example was no where close to what is specified)

I guess each builder has to answer that question for them self, but if it is true, then I guess every RV built should have a BRS system installed.

Walt

Well Known Member

Is it a valid argument to install a safety related part for an issue that was caused by a flagrant construction error? (Pretty sure this example was no where close to what is specified)

I guess each builder has to answer that question for them self, but if it is true, then I guess every RV built should have a BRS system installed.

I'm sure no one makes errors building.

BRS-lots of downsides, what exactly is the downside of installing this OC bracket? (Van's obviously thought the POS Molex connector was more important)

Last edited:

jcbarker

Well Known Member

Anyway... Since I was the one that started this latest discussion on the travel limiting bracket, I want to say thank you for everyone's perspective and the links to past discussions. Very informative.

I think I've come full circle:

- remove the Molex mount feature on the servo bracket

- switch from Molex to D-Sub.

Cheers,

I think I've come full circle:

- remove the Molex mount feature on the servo bracket

- switch from Molex to D-Sub.

Cheers,

mc607

Well Known Member

I’ve read on VAF that the Molex connectors are not a favourite of some builders. If the Molex connectors are assembled as designed, with proper tools and techniques, are connected properly, and function properly during testing with no issues, what happens to them over time to garner the bad reputation? Does the plastic degrade and become brittle, do the pins degrade and or corrode prematurely?

I’m always trying to make my build decisions, and more importantly, deviations from KAI on facts, not opinions. Pictures are always helpful. Thanks in advance,

Todd

I’m always trying to make my build decisions, and more importantly, deviations from KAI on facts, not opinions. Pictures are always helpful. Thanks in advance,

Todd

Last edited:

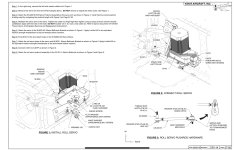

I commented on this a while ago..Glad I installed the stop bracket

Scott, I agree that the push-pull rods are a good safety device to prevent the servos from going over center, but being a belt-and-suspenders type, I still hate to eliminate a safety feature like the stop bracket. It's possible a badly-adjusted linkage or incorrect servo arm install could still let the arm go over center. Also, other parts of the linkage may fail or be damaged somehow. For example, the length of the arm which transfers the servo force to the bellcrank (circled) has a fair amount of leverage all concentrated on that nut plate (arrow) and if it should loosen or bend, conceivably the servo arm could also go over center...

On a flight using A/P, loads on that nut plate can cycle back and forth thousands of times, so the mounting rivets get a good workout

Last edited:

RVbySDI

Well Known Member

I commented on this a while ago..Glad I installed the stop bracket

Scott, I agree that the push-pull rods are a good safety device to prevent the servos from going over center, but being a belt-and-suspenders type, I still hate to eliminate a safety feature like the stop bracket. It's possible a badly-adjusted linkage or incorrect servo arm install could still let the arm go over center. Also, other parts of the linkage may fail or be damaged somehow. For example, the length of the arm which transfers the servo force to the bellcrank (circled) has a fair amount of leverage all concentrated on that nut plate (arrow) and if it should loosen or bend, conceivably the servo arm could also go over center...

On a flight using A/P, loads on that nut plate can cycle back and forth thousands of times, so the mounting rivets get a good workout

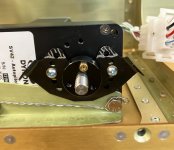

View attachment 44389

One thing is very obvious in this pic. That connector sure looks like a much neater installation and a more secure connection than the molex connectors that come stock with the 14 harnesses.

not sure if there's room to mount the link on the inside of the arm...it would be pretty close I think, and would put the ball end and arm very close to other hardware...

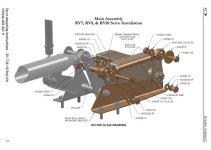

It's been a long time since I did this, but I think I just followed the Dynon instructions for the rv-7-8-10 ( the -10 wing is the same as the -14, only a couple of rib bays longer)

https://dynonavionics.com/includes/guides/RV7-8-10_Roll_Kit_Instructions_Rev_H.pdf

(pics at the end of the document)

At the time (2017) Van's was showing the nut plate for attaching the push rod to the bellcrank. I like the Dynon install better with the nut and bolt arrangement.

It's been a long time since I did this, but I think I just followed the Dynon instructions for the rv-7-8-10 ( the -10 wing is the same as the -14, only a couple of rib bays longer)

https://dynonavionics.com/includes/guides/RV7-8-10_Roll_Kit_Instructions_Rev_H.pdf

(pics at the end of the document)

At the time (2017) Van's was showing the nut plate for attaching the push rod to the bellcrank. I like the Dynon install better with the nut and bolt arrangement.

Last edited:

I kinda get the impression that the servos were designed for the pushrod to mount on the outside of the arm. All the older pics show this. Then when they realized the connection to the bellcrank was too long, they moved the pushrod to the inside, but encountered clearance problems and tried fixing that with the countersunk head screw or fasteners with thinner heads....

The older pics also show the pushrod mounted to the outermost hole on the arm, while the newer ones show it on the innermost hole. Maybe a concern was that with minimum clearance, the hardware mounting the pushrod to the arm could catch on the servo body and jam the system...

Whatever works, just be sure to use the OC bracket

The older pics also show the pushrod mounted to the outermost hole on the arm, while the newer ones show it on the innermost hole. Maybe a concern was that with minimum clearance, the hardware mounting the pushrod to the arm could catch on the servo body and jam the system...

Whatever works, just be sure to use the OC bracket

Last edited: