Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RV 6 tail

- Thread starter 38f

- Start date

Check with the plans. But I’m sure that the tail plane attachment needs to go through the upper fuselage longerons. (Often an area of mistakes with edge distance)

I certainly wouldn’t fly it until it was rectified. Then I’d get an RV experienced builder or A&P to go over the entire aircraft, as if the builder allowed this, you don’t know what else is hidden.

I certainly wouldn’t fly it until it was rectified. Then I’d get an RV experienced builder or A&P to go over the entire aircraft, as if the builder allowed this, you don’t know what else is hidden.

Last edited:

PaulvS

Well Known Member

As kiwipete said the horizontal stabiliser must be bolted through the longeron, per the plans, whereas this one hasn't apparently been done correctly.

I personally wouldn't fly in it because the structural integrity is compromised in a critical assembly.

Suggest checking the W&B because the ELT weight back there is going to affect the CG.

The bolts through the spar web to the vertical stabiliser are also not per plans.

I personally wouldn't fly in it because the structural integrity is compromised in a critical assembly.

Suggest checking the W&B because the ELT weight back there is going to affect the CG.

The bolts through the spar web to the vertical stabiliser are also not per plans.

Last edited:

I wouldn't fly it in that condition. Aside from the deviations from the plans already mentioned, 2 other observations.

That small hole looks like it could be a stop drill, which makes me question whether the black line extending rightward from it is further crack propagation in the crotch of the angle. maybe its just a black mark?

Also, what is the grey stuff under the bolt head?

EDIT: Just noticed too that the nose ribs are not relieved on the upper and lower flange areas so that they sit flush on the spar web bur rather are riveted to the angles leaving a big gap at the rear flange.

That small hole looks like it could be a stop drill, which makes me question whether the black line extending rightward from it is further crack propagation in the crotch of the angle. maybe its just a black mark?

Also, what is the grey stuff under the bolt head?

EDIT: Just noticed too that the nose ribs are not relieved on the upper and lower flange areas so that they sit flush on the spar web bur rather are riveted to the angles leaving a big gap at the rear flange.

Last edited:

Also the angle splice is not flush on the aft deck. Seeing the washer on the middle bolt make me suspect it’s sitting on top of a rivet in each longeron that should not be there.

That being said, look at the underside of the aft deck. Just speculation but I think you will see the offending rivets.

To answer the original question, no I would not fly this plane.

That being said, look at the underside of the aft deck. Just speculation but I think you will see the offending rivets.

To answer the original question, no I would not fly this plane.

JonJay

Well Known Member

Lots wrong as noted, and I would look carefully at the entire tail, if not airplane, for other plan “deviations”.

The good news, he can now do the HS SB and not feel like you’re taking apart a perfectly good HS. Consider this an opportunity.

Good catch on the inspection but this area is one that has been historically the worst for build error.

Most of the time it’s edge distance issues, but have seen this “floating” HS Spar issue before, on airplanes that have flow for many hours. Scary, but also a testimonial for how robust this design is when properly executed.

I would check this area before I bought any RV, and certainly that machine is grounded!

The good news, he can now do the HS SB and not feel like you’re taking apart a perfectly good HS. Consider this an opportunity.

Good catch on the inspection but this area is one that has been historically the worst for build error.

Most of the time it’s edge distance issues, but have seen this “floating” HS Spar issue before, on airplanes that have flow for many hours. Scary, but also a testimonial for how robust this design is when properly executed.

I would check this area before I bought any RV, and certainly that machine is grounded!

Last edited:

That plane needs A SERIOUS inspection. Builder clearly was not paying attention to much. That spar MUST be bolted into the longeron. Further, the guy stuck a bunch of shims under the middle of the spar, causing it to bow upward. These are very disturbing signs and would expect to find MANY more problems upon closer examination. I have inspected quite a few RVs and when I see stuff like that it is NEVER isolated to one area; It is ALWAYS pervasive. It is one thing to blow the edge distance in that spot (75% of all planes I have inspected have that mistake) but totally different animal to completely skip a critical structural fastener; Complete lack of discipline vs newbie error.

Tell your friend that EAB planes NEED thorough pre buy inspections. If it was inspected have him suggest that his friends not use that inspector. That spot is the highest recurring error spot in RVs and any inspector should know that.

Tell your friend that EAB planes NEED thorough pre buy inspections. If it was inspected have him suggest that his friends not use that inspector. That spot is the highest recurring error spot in RVs and any inspector should know that.

Last edited:

BillL

Well Known Member

Ground Immediately!!

The bolts across there should attach to the longhorns. The center is in a thin bulkhead, not structure - even if the bolt goes through a cross angle - it is very poor structure for this loading. Something weird is going on under that bulkhead and a photo under there should tell something of what is happening.

No one should fly in this plane.

It may be easy for a builder to fix, notwithstanding any underlying structure repairs. That is TBD and potentially serious.

It should be an RV expert not just A&P.

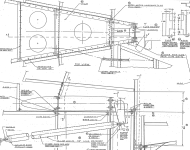

Someone at the airport bought this 6

During inspection found this would you fly it this way

The bolts across there should attach to the longhorns. The center is in a thin bulkhead, not structure - even if the bolt goes through a cross angle - it is very poor structure for this loading. Something weird is going on under that bulkhead and a photo under there should tell something of what is happening.

No one should fly in this plane.

It may be easy for a builder to fix, notwithstanding any underlying structure repairs. That is TBD and potentially serious.

It should be an RV expert not just A&P.

Last edited:

Scott Hersha

Well Known Member

Vans has a gussetted mod that was designed for those airplanes that ended up with minimal edge distance issues with the HS angle to longeron bolt attachment. This may work for you to make repairs for your airplane. It will most likely be necessary to remove your HS to make these repairs - as well as other repairs that others have pointed out in this post. I’m sure you have contacted Vans Aircraft by now, and should go with whatever they recommend. While that HS is off the airplane, consider fully complying with any SB’s relative to the HS that apply to your airplane.

Vans has a gussetted mod that was designed for those airplanes that ended up with minimal edge distance issues with the HS angle to longeron bolt attachment. This may work for you to make repairs for your airplane. It will most likely be necessary to remove your HS to make these repairs - as well as other repairs that others have pointed out in this post. I’m sure you have contacted Vans Aircraft by now, and should go with whatever they recommend. While that HS is off the airplane, consider fully complying with any SB’s relative to the HS that apply to your airplane.

It doesn’t look like the bolt ( there should actually be two) even goes through any part of the longeron so a proper repair will likely need more than just adding the gusset/doubler fix.

I know my opinion is the lowest form of fact but if it were me, this is what I would do.

I would pull the HS. Remove the inboard ribs and replace the splice angle. And reinstall the ribs with the ends properly on the spar. I suspect there are rivets under the current splice angle. Remove those and when drilling the new angle, try to hit those holes. If not possible to match drill thru those rivet holes, install a doubler on the longeron and drill thru fresh metal.

While the tail is off, thoroughly go over the entire empannage AND the aft fuselage in case there are more gotchas. I probably would inspect first before repairing the HS in case parts need to be ordered from Vans other than a spice angle and the service bulletin kit (good timing to do).

Properly repaired, it will be good as new. Maybe even better because you know it is right and you will have piece of mind.

Good luck on whatever is done.

I would pull the HS. Remove the inboard ribs and replace the splice angle. And reinstall the ribs with the ends properly on the spar. I suspect there are rivets under the current splice angle. Remove those and when drilling the new angle, try to hit those holes. If not possible to match drill thru those rivet holes, install a doubler on the longeron and drill thru fresh metal.

While the tail is off, thoroughly go over the entire empannage AND the aft fuselage in case there are more gotchas. I probably would inspect first before repairing the HS in case parts need to be ordered from Vans other than a spice angle and the service bulletin kit (good timing to do).

Properly repaired, it will be good as new. Maybe even better because you know it is right and you will have piece of mind.

Good luck on whatever is done.

Last edited:

So, as a new "builder" myself - the biggest issue here is the lack of attachment bolts being through the longerons per the plans, correct?

Just trying to understand what I'm looking at and the issues within.

While that is a critical flaw that should ground the plane, the bigger issue is the skill of the person that made that error and this brings into question EVERY OTHER decision that he/she made. NO ONE should get in that plane until an RV expert goes through it with a fine tooth comb. I can all but promise it is not the only error.

JonJay

Well Known Member

So, as a new "builder" myself - the biggest issue here is the lack of attachment bolts being through the longerons per the plans, correct?

Just trying to understand what I'm looking at and the issues within.

That’s correct. Be very careful when you drill these holes. The edge distances are very tight and allow very little tolerance for error. When you get to this stage, search for all of the posts that talk about techniques to insure you do this correctly.

When edge distances in this area started to be revealed as a common builder flaw, years ago, I went back and inspected mine just to make sure I did it correctly. I would encourage every RV owner to inspect this area carefully. There are a lot of airplanes flying out there still with edge distance errors in this area.

Last edited:

I can all but promise it is not the only error.

I'm sure. The mentality that allows them to deviate from the plans that far, in that portion of the build, would be hard to contain throughout the build.