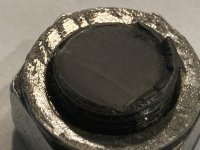

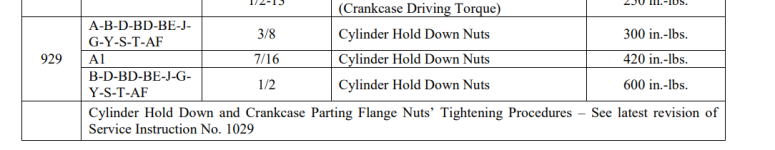

Yesterday, I pulled our RV-8 (IO-360 Angle Valve) into the hangar for an oil change. Engine running great, great oil analysis, very low oil consumption and very high 70's compressions. Drained, refilled and cut the filter which was about as clean as I've ever seen. I went home happy. Today, I went back to the hangar to wash down the engine and do a leak check test run. After the wash down, I was using the compressed air to dry down the engine when I noticed one of the large (thru bolt) #3 cylinder studs was broken. On closer examination, the smaller stud next to it was broken also. After searching for just a few minutes with a magnet, I found the large nut and thru bolt piece. The engine has 403.3 hours TSMO and was overhauled at a reputable (now closed) facility. Despite some local opinions that it's possible to just replace the stud and through bolt and go on, I called two very well known experts and expressed my concern that the thru bolt provides clamping force on the bearings and it has obviously lost that clamping force. Both experts agreed that it should be torn down and inspected/repaired. It's coming off and heading to an engine shop next week. Contrary to what we like to joke about, my wife fully supports the expense.

So, why do I say it's a great day? First, I am in a partnership with my son (A-10, now Delta) and he and I agree that safety is the absolute #1 priority and we can split the cost. Next, we both have the resources to do this without missing meals. Lastly, and most importantly, we caught this before something happened that would forever change a real joy in our lives (RV-8) into a potentially catastrophic event.

Please, please pay special attention when you're doing your inspections. From this point on, I will look at every visible cylinder bolt, every time I have the cowl off.

So, why do I say it's a great day? First, I am in a partnership with my son (A-10, now Delta) and he and I agree that safety is the absolute #1 priority and we can split the cost. Next, we both have the resources to do this without missing meals. Lastly, and most importantly, we caught this before something happened that would forever change a real joy in our lives (RV-8) into a potentially catastrophic event.

Please, please pay special attention when you're doing your inspections. From this point on, I will look at every visible cylinder bolt, every time I have the cowl off.

Attachments

Last edited: