Two things.

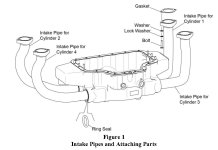

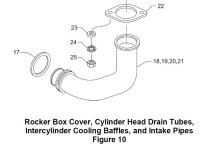

First question. Does anyone have advice or a written procedure for replacing the intake tube seals on the sump end of the tube? Photos below.

I have gotten some great advice from a respected member of VAF about trouble shooting my problem but just casting a wider net.

Second question. Can an intake leak on the intake tube cause a massive backfire? The backfires during hot starts have blown out the air filter several times. Always on a hot start. It happens whether I start on the left impulse Slick, right P-Mag or both. It happens when the mixture is being pushed in as it's trying to start.

I've had experienced mechanics and pilots watch me hot start and find nothing wrong with my technique (I've tried every technique I can think of.

First question. Does anyone have advice or a written procedure for replacing the intake tube seals on the sump end of the tube? Photos below.

I have gotten some great advice from a respected member of VAF about trouble shooting my problem but just casting a wider net.

Second question. Can an intake leak on the intake tube cause a massive backfire? The backfires during hot starts have blown out the air filter several times. Always on a hot start. It happens whether I start on the left impulse Slick, right P-Mag or both. It happens when the mixture is being pushed in as it's trying to start.

I've had experienced mechanics and pilots watch me hot start and find nothing wrong with my technique (I've tried every technique I can think of.

Last edited: