I've only ever flown carburated airplanes, so I haven't had to deal with hot start problems. Presumably a major draw of EFI is that hot starts are no problem, but I'm not super keen on the added cost and complexity. How bad is the hot start problem with mechanical fuel injection really?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How bad is the hot start issue, really?

- Thread starter gotyoke

- Start date

Not that bad

I have the original IO390 in my RV-14, stock fuel injectors. I’ve only had difficulty with a hot start on one occasion, when I flooded it. But even then, following my Flooded Engine checklist, I got it started right up. I’ve done a lot of hot starts in about 335 hours so far. I generally think nothing of it; it’s just a slightly different procedure.

I have the original IO390 in my RV-14, stock fuel injectors. I’ve only had difficulty with a hot start on one occasion, when I flooded it. But even then, following my Flooded Engine checklist, I got it started right up. I’ve done a lot of hot starts in about 335 hours so far. I generally think nothing of it; it’s just a slightly different procedure.

erich weaver

Well Known Member

I don’t consider it a drawback at all. Never been an issue. Just follow the recommended hot start procedure and it starts. I really don’t consider fuel injection more complex either. I have 900 hours now with next to nothing maintenance wise.

It's not a hot start "problem" unless you do the wrong procedure. Try and start a carburated airplane with a FI hot start technique and we'll find a whole new "problem starting" thing to worry about.

I have 1500 hours split between all 4 combinations of Lycoming and Continental (470, 520) injected and carbureted engines. Do the right technique for the appropriate fuel metering system, and none of them are a problem.

I have 1500 hours split between all 4 combinations of Lycoming and Continental (470, 520) injected and carbureted engines. Do the right technique for the appropriate fuel metering system, and none of them are a problem.

Kyle Boatright

Well Known Member

IMO, carb'd engines are a no-brainer to start.

Injected engines, particularly when warm, require more specific/appropriate technique. If you follow best practices, you'll get it started. If you don't follow best practices, you'll have bad experiences.

So, there is a difference in the expertise required...

Injected engines, particularly when warm, require more specific/appropriate technique. If you follow best practices, you'll get it started. If you don't follow best practices, you'll have bad experiences.

So, there is a difference in the expertise required...

MacCool

Well Known Member

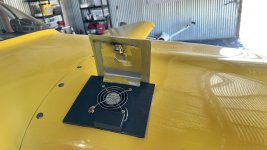

Hot start technique notwithstanding, I have also gone to some lengths to manage temps under the cowl, including insulating the fuel lines and exhaust shielding.

In addition, to try to mitigate the under-cowl heat problem on short turn-arounds, I built a cowl exhaust fan that runs on a 1-hour timer, powered through the charger pitgail, that I plop into the oil door opening. It's an 80mm 12v fan that moves about 72 CFM. Simple to hook up, negligible current draw.

..

In addition, to try to mitigate the under-cowl heat problem on short turn-arounds, I built a cowl exhaust fan that runs on a 1-hour timer, powered through the charger pitgail, that I plop into the oil door opening. It's an 80mm 12v fan that moves about 72 CFM. Simple to hook up, negligible current draw.

..

Attachments

Or you can get one of these nicely made units. https://airflowperformance.com/index.php/product/counter-clock-wise-purge-valve-assy/Mine showed up on Friday with my complete FI system from AFI.

Steve Barnes

Well Known Member

No problem whatsoever

When did ever see fuel injected planes sitting on the ramp with dead batterys? I fly in to Auburn about once or twice a month to meet the RV guys for brunch.

Steve

When did ever see fuel injected planes sitting on the ramp with dead batterys? I fly in to Auburn about once or twice a month to meet the RV guys for brunch.

Steve

No problem once you get the formula that works for your airplane. For my IO-360 it is just run the boost pump until the pressure come up, a little throttle, then crank, realizing it will take about four blades to catch, mixture rich as soon as it catches.

What Johnsey says.

Each plane seems to need a different procedure.

Once you get it, no need for added equipment.

Maybe I am not as smart as the other posters but I always had issues starting my IO360 if it was sitting between 30min and 2h. More was OK less was OK within that time I still got it started but with much more cranking then I liked.

I bought a PMAG and since then it just starts. Best money I spend on the engine.

Oliver

I bought a PMAG and since then it just starts. Best money I spend on the engine.

Oliver

ronrapp

Well Known Member

In addition, to try to mitigate the under-cowl heat problem on short turn-arounds, I built a cowl exhaust fan that runs on a 1-hour timer, powered through the charger pitgail, that I plop into the oil door opening. It's an 80mm 12v fan that moves about 72 CFM. Simple to hook up, negligible current draw...

Despite the high compression, I have no problem hot starting the 195 hp IO-360 in my RV-6, but your post reminded me of a mid-wing Extra 300 I used to fly a lot. We used it for advanced spin courses, high performance aerobatic training, and competition coaching/prep, so the plane got a lot of use and often it would only be on the ground for maybe 45 minutes before we'd be starting it up again.

That AEIO-540 was tough to hot start, so after shutdown we'd put a high speed 20" cage fan on the ground underneath the engine and open the oil door. as soon as it was rolled back into the hangar. You could see the hot air venting through the air inlets and oil door.

It didn't lower the oil temp as much as you might expect, but it did make hot starting much easier. Without it -- say, when we were at an aerobatic competition -- that engine would vapor lock in the worst way.

The only other airplane I ever really had a tough time hot starting was an SR-20, but eventually that was traced to some seriously mis-timed magnetos.

--Ron

The worst part about hot starts is when you see some other poor soul struggling to get their engine started.

You feel terrible for them, particularly when they have passengers, or they are holding up the line at the fuel station.

Worse is when some well-meaning passer-by starts giving them suggestions, mostly conflicting with the "right way".

Sweat is flowing, fuel is dripping, electrons are scattered everywhere. It always works out in the end, after a brief pause, a gentle push away from the fuel station, and sometimes a bit of juice from a start cart.

I think every pilot should read DanH's writeup of the goldilocks sweep method of getting an ICE started. Even though I've been messing with engines since I was about 5 years old, that description really clarified how to deal with a hot start situation.

You feel terrible for them, particularly when they have passengers, or they are holding up the line at the fuel station.

Worse is when some well-meaning passer-by starts giving them suggestions, mostly conflicting with the "right way".

Sweat is flowing, fuel is dripping, electrons are scattered everywhere. It always works out in the end, after a brief pause, a gentle push away from the fuel station, and sometimes a bit of juice from a start cart.

I think every pilot should read DanH's writeup of the goldilocks sweep method of getting an ICE started. Even though I've been messing with engines since I was about 5 years old, that description really clarified how to deal with a hot start situation.

planenutz

Well Known Member

As has been stated above, if you use the right procedure then its largely a non-issue. For example, the best way to start a hot Lycoming is not the same as the best way to start a hot Continental and then to add to the confusion there are old wives tales, pet favourites and lots of opinions. Usually, if you follow the recommendations of the fuel control manufacturer and take time to understand what it is you're doing and why, then you'll probably never have a problem unless your battery is in poor condition.

Don't be afraid of buying a fuel injection system - the advantages outweigh the disadvantages and once you have a few hours under your belt you'll be fine. To avoid the possible rough running immediately after start you could always go for the Airflow Performance system but its not a MUST have, just a VERY NICE to have.

Don't be afraid of buying a fuel injection system - the advantages outweigh the disadvantages and once you have a few hours under your belt you'll be fine. To avoid the possible rough running immediately after start you could always go for the Airflow Performance system but its not a MUST have, just a VERY NICE to have.

blaplante

Well Known Member

usually a total non-issue. BUT, where I've had issues is 'warm' starts. The plane sat long enough so it is no longer hot, but not cold either. If you guess wrong on procedure and have a weak battery you can get stuck. Happened to me once in 300 hours. Either you assume it is cold and flood it, or you assume it is hot and keep cranking waiting for it to fire and run down the battery.

The difficulty is both act the same.... cranking and nothing happening.

My latest WARM start procedure is like a hot start but if after a few revolutions it isn't firing, then slowly start advancing the mixture while cranking. Typically starts weakly firing... keep on the starter and with more mixture it gets happy.

The difficulty is both act the same.... cranking and nothing happening.

My latest WARM start procedure is like a hot start but if after a few revolutions it isn't firing, then slowly start advancing the mixture while cranking. Typically starts weakly firing... keep on the starter and with more mixture it gets happy.

Toobuilder

Well Known Member

Even bone stock bendix FI and mags is no problem as long as you understand that the "right" way only gets you in the ballpark (and is probably good enough for most of the airplanes out there), but EVERY tail number has nuances that are unique. Many times these nuances are subtle, but they do define the personality of that airplane and understanding them is key to reliable starts. Once you figure out the difference between a 10 minute turn at the pumps from a 1 hour turn at breakfast for YOUR airplane, you are good to go. But it has been my experience that rote procedure from the guy next to you or even the POH is just as often wrong as it is right.

I have been flying bendix FI airplanes for 20 years and they all behave differently - but I long ago overcame my "hot start anxiety". In the those 20 years I can count on one hand the times the airplane DID NOT start on the first try, and I've certainly never depleted a battery during a start attempt.

I have been flying bendix FI airplanes for 20 years and they all behave differently - but I long ago overcame my "hot start anxiety". In the those 20 years I can count on one hand the times the airplane DID NOT start on the first try, and I've certainly never depleted a battery during a start attempt.

MacCool

Well Known Member

I don't think that the engine/oil temp is necessarily the direct issue...it's more likely the high under-cowl temps and their effect on the fuel in the fuel lines, so my attempt to solve the issue focused on exhausting as much of that hot air as practical while naturally bringing cooler ambient air during the 30-120 minute time frame that seems to be most problematic.Despite the high compression, I have no problem hot starting the 195 hp IO-360 in my RV-6, but your post reminded me of a mid-wing Extra 300 I used to fly a lot. We used it for advanced spin courses, high performance aerobatic training, and competition coaching/prep, so the plane got a lot of use and often it would only be on the ground for maybe 45 minutes before we'd be starting it up again.

That AEIO-540 was tough to hot start, so after shutdown we'd put a high speed 20" cage fan on the ground underneath the engine and open the oil door. as soon as it was rolled back into the hangar. You could see the hot air venting through the air inlets and oil door.

It didn't lower the oil temp as much as you might expect, but it did make hot starting much easier. Without it -- say, when we were at an aerobatic competition -- that engine would vapor lock in the worst way.

The only other airplane I ever really had a tough time hot starting was an SR-20, but eventually that was traced to some seriously mis-timed magnetos.

--Ron

I haven't used that oil door vent fan enough to definitively prove its effectiveness, but it was simple to build, and about $25 in readily-available parts. "Can't hurt/might help", so....

I will say that as I reasoned that "more is better", I opted for a higher-speed/volume fan. It moves a lot of air but is far from silent. For the 1 hour that it runs, it does tend to attract attention on the ramp.

Last edited:

Jpm757

Well Known Member

I am running a YIO-360 M1B w/Avstar F.I. with no return line. After shutdown using the mixture, I notice the fuel pressure increases to 40-45 psi almost immediately. Richening the mixture momentarily after shutdown drops the pressure down to zero, and helps alleviate vapor lock. Also leaving the throttle partially open seems to help, especially on a "hot" quick turn.

They say every engine is different, but once you figure out what works for your engine it will work every time.

The basic idea is on a hot-start, mixture to cut-off, throttle cracked to maybe halfway, crank, and as the engine fires move the mixture in quickly and pull the throttle back to idle. About the fifth or sixth time you try this you'll figure out the timing and it will be no problem.

High pressure fuel rails like EFII and SDS make it a total non-issue - but dealing with it on a standard injection system does not require magic either.

The basic idea is on a hot-start, mixture to cut-off, throttle cracked to maybe halfway, crank, and as the engine fires move the mixture in quickly and pull the throttle back to idle. About the fifth or sixth time you try this you'll figure out the timing and it will be no problem.

High pressure fuel rails like EFII and SDS make it a total non-issue - but dealing with it on a standard injection system does not require magic either.

Dugaru

Well Known Member

This is a brilliant gadget

Does it have any appreciable effects on CHTs in the climb after a lunch stop on a hot day?

Does it have any appreciable effects on CHTs in the climb after a lunch stop on a hot day?

Hot start technique notwithstanding, I have also gone to some lengths to manage temps under the cowl, including insulating the fuel lines and exhaust shielding.

In addition, to try to mitigate the under-cowl heat problem on short turn-arounds, I built a cowl exhaust fan that runs on a 1-hour timer, powered through the charger pitgail, that I plop into the oil door opening. It's an 80mm 12v fan that moves about 72 CFM. Simple to hook up, negligible current draw.

..

Maybe I am not as smart as the other posters but I always had issues starting my IO360 if it was sitting between 30min and 2h. More was OK less was OK within that time I still got it started but with much more cranking then I liked.

I bought a PMAG and since then it just starts. Best money I spend on the engine.

Oliver

I think there is something to this as a good EI system will light mixtures a mag can’t.