Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel flow / red cube

- Thread starter bob888

- Start date

I had to replace mine at 200 hours. The company said no repairs are possible but offered a discount for a new one.

RV8JD

Well Known Member

It seems like 750 hours is an usually long time for a red cube to live. Mine went 400 hours and I thought that was doing pretty well.

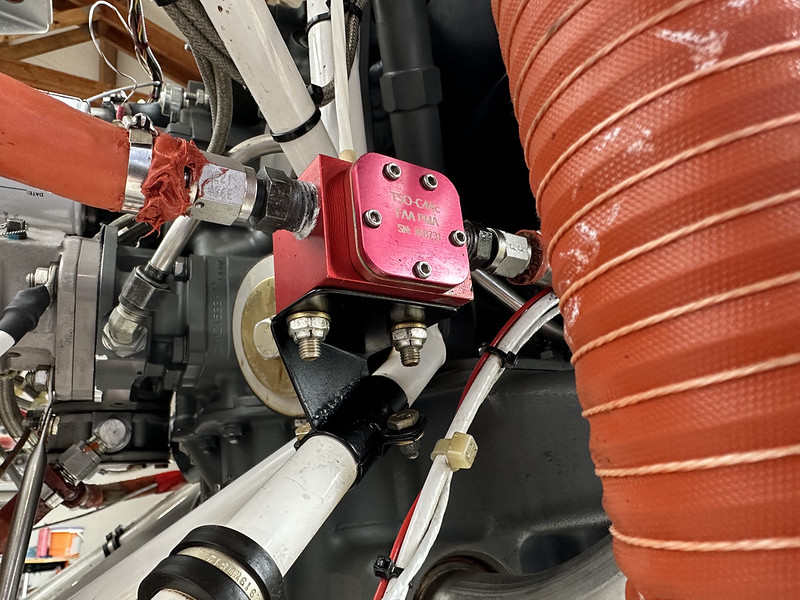

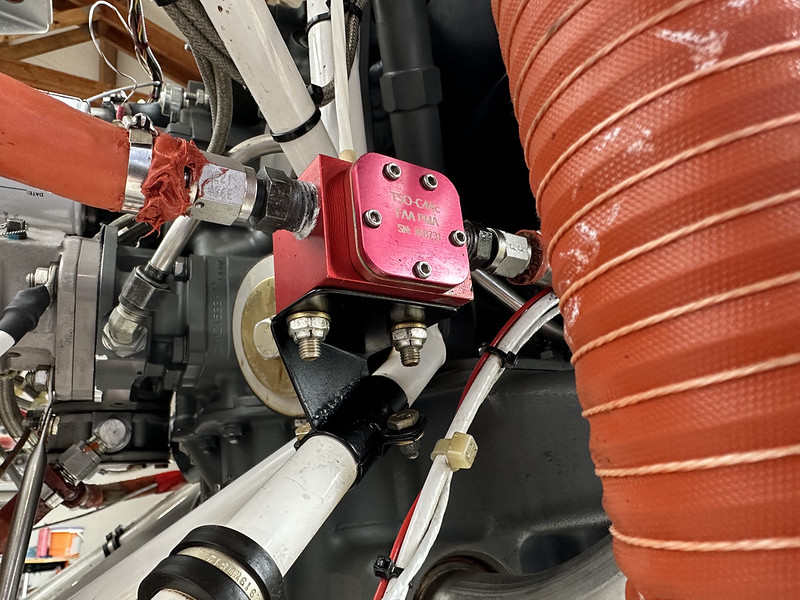

Another data point: My FT-60 Red Cube has 1397 Hobbs hours on it so far. No problems. (And I hope this post doesn't jinx me!).

Installation pic:

Last edited:

Carl Froehlich

Well Known Member

1800+ hours on the Red Cube in my first RV-10.

Carl

Carl

Desert Rat

Well Known Member

It would be interesting to see if there'e any kind of correlation between the location of the cube and how long they last.

Is there any kind of general consensus on that or are the early failures just random?

Is there any kind of general consensus on that or are the early failures just random?

I believe DanH took a red cube apart and it had only one moving part - a wheel that triggers pulses to indicate its rotation speed. Normal wear would eventually make that wheel stop turning smoothly, and vibration would probably accelerate that wear.

Having the device in a place with less vibration should extend its life.

That said, mine is bolted to the engine, and is still working ok after about 300 hours. We may need to simply consider these things as consumables, like plugs and oil. Hopefully someday the ultrasonic fuel flow sensors will come down in price and replace these mechanical devices.

Having the device in a place with less vibration should extend its life.

That said, mine is bolted to the engine, and is still working ok after about 300 hours. We may need to simply consider these things as consumables, like plugs and oil. Hopefully someday the ultrasonic fuel flow sensors will come down in price and replace these mechanical devices.

Terry, there doesnt seem to be any correlation between install locations and failures. Weve seen them mounted just about everywhere you can think of, some make more sense than others. We've been dealing with the cubes since 2010 and Ive never heard of the shutter wheel breaking, stopping, or otherwise not being able to rotate past the shutter wheel. (This doesnt include foreign objects obstructing the inlet port, only free-flowing fuel wheel failures). So the failures that are happening seem to be electrical. Dan's autopsy of the cube several years ago, show its simplicity, but also the very tiny wires that seem susceptible.

I think the success rate might depend on the service loop of the harness, and making sure there is no strain on the wires near the cube body. That appears to be the vulerable point.

Tom

I think the success rate might depend on the service loop of the harness, and making sure there is no strain on the wires near the cube body. That appears to be the vulerable point.

Tom

T So the failures that are happening seem to be electrical. Dan's autopsy of the cube several years ago, show its simplicity, but also the very tiny wires that seem susceptible. \

Tom

I also believe it is not the wheel or it's bearings. It uses an electric light generator and an opto-electric sensor. So several chips to fail (heat is likely worse than vibration here) as well as a plastic window that can become too opaque for various reasons.

Larry

Bill Boyd

Well Known Member

Starting to look like the main failure is of the market to behave as designed.

Customer pushback on the abysmal failure rate in these devices should incentivize the makers to give us a more robust design. If there was a more reliable alternative in place, we could vote with our wallets.

Then again, the likes of MicroSoft have been getting away with shoddy goods for decades, using the deficiencies to sell upgrades called "versions." Why should the flow sensor industry not ride the same train

Customer pushback on the abysmal failure rate in these devices should incentivize the makers to give us a more robust design. If there was a more reliable alternative in place, we could vote with our wallets.

Then again, the likes of MicroSoft have been getting away with shoddy goods for decades, using the deficiencies to sell upgrades called "versions." Why should the flow sensor industry not ride the same train

Pilot135pd

Well Known Member

Terry, there doesnt seem to be any correlation between install locations and failures. Weve seen them mounted just about everywhere you can think of, some make more sense than others. We've been dealing with the cubes since 2010 and Ive never heard of the shutter wheel breaking, stopping, or otherwise not being able to rotate past the shutter wheel. (This doesnt include foreign objects obstructing the inlet port, only free-flowing fuel wheel failures). So the failures that are happening seem to be electrical. Dan's autopsy of the cube several years ago, show its simplicity, but also the very tiny wires that seem susceptible.

I think the success rate might depend on the service loop of the harness, and making sure there is no strain on the wires near the cube body. That appears to be the vulerable point.

Tom

I have a Floscan 201 that's been giving me issues and I'm currently troubleshooting it with the company. That one says to install it in a 45 degree upslope for bubbles. The picture provided previously here for the Red Cube shows it flat horizontally. What is your experience installing it as I'm most likely going to end up buying a red cube to replace the Floscan if I can't get it working this week?

Just ran across this video of someone taking apart a "gold cube" which is very similar to the "red cube" on the EuroGA forum:

https://www.youtube.com/watch?v=HXJMLcpcl10

https://www.youtube.com/watch?v=HXJMLcpcl10

Richard Connell

Well Known Member

Starting to look like the main failure is of the market to behave as designed.

Customer pushback on the abysmal failure rate in these devices should incentivize the makers to give us a more robust design. If there was a more reliable alternative in place, we could vote with our wallets.

Then again, the likes of MicroSoft have been getting away with shoddy goods for decades, using the deficiencies to sell upgrades called "versions." Why should the flow sensor industry not ride the same train

Yes in theory, but I think the customer base is too small and the builder as at time of building is not as well informed as he is by the time the aircraft has a failure. Often this is many many years later.

Airframe and avionics manufacturers specify the part and builders blindly install.

Just look at alternators for example. There’s a new thread every week on a certain brand of alternator, yet people still install them in large numbers despite a well proven superior alternative.

I also believe it is not the wheel or it's bearings. It uses an electric light generator and an opto-electric sensor. So several chips to fail (heat is likely worse than vibration here) as well as a plastic window that can become too opaque for various reasons.

Larry

Agree - I think the primary issue is heat related failure. No one that I know of yet has instrumented the Red Cube for temperature (DanH did you?). But considering that a popular, and recommended by Van's in the -14, place to mount it is right next to the cherry red #4 exhaust header, it's not surprising to see them fail.

Tj is process dependent, but is somewhere in the 150°C - 170°C (302°F to 338°F) range -- the EGT is ~1300°F for argument sake, so it wouldn't surprise me in the least if the cube itself got to 400°F externally.

PilotjohnS

Well Known Member

Mounting location

So mine is mounted on the lower right corner of the firewall.

It seems to receive a lot of heat from the oil cooler outflow.

I was think of relocating the red cube or adding fiberglass ducting to keep the oil cooler heat from hitting it.

So mine is mounted on the lower right corner of the firewall.

It seems to receive a lot of heat from the oil cooler outflow.

I was think of relocating the red cube or adding fiberglass ducting to keep the oil cooler heat from hitting it.

We've seen them mounted in various places and attitudes, including our verticle location at the flow divider. NONE of them that Ive seen have had a flow induced issue, its been electrical--or like Larry stated above, the photo cell thingy. I cant speak of the electronics, but as long as fuel flows--consistantly-- and turns the shutter wheel, thats where our involvement ends. Constistantly is the operative word---and by that I mean HOPEFULLY constant flow, little to no air bubbles that 'might' change the way the shutter wheel works- (Doubt it), and good connections.

The vertical install works well----Dan Horton and many others have it on their planes, and it seems to work well. Same with the horizontal install.

Tom

The vertical install works well----Dan Horton and many others have it on their planes, and it seems to work well. Same with the horizontal install.

Tom

PilotjohnS

Well Known Member

Full floating

Can i mount the red cube floating on the fuel lines?

So, like the red cube is supported by the in and out fuel lines, or is this problematic?

Can i mount the red cube floating on the fuel lines?

So, like the red cube is supported by the in and out fuel lines, or is this problematic?

db1yg

Well Known Member

Cube Location

Mine has been suspended in the metered fuel line for years with no problem and good accuracy. I have my metered line running up the back of the engine and through the rear baffle wall to the divider--the cube is half way up on the back.

As a note, the Mooney 201 I flew for years also had its factory fuel flow transducer mounted and suspended in the line from the mechanical pump to the servo.

Cheers,

db

Mine has been suspended in the metered fuel line for years with no problem and good accuracy. I have my metered line running up the back of the engine and through the rear baffle wall to the divider--the cube is half way up on the back.

As a note, the Mooney 201 I flew for years also had its factory fuel flow transducer mounted and suspended in the line from the mechanical pump to the servo.

Cheers,

db

Pilot135pd

Well Known Member

That's where I have mine, between the engine pump and the fuel injection body.

Can i mount the red cube floating on the fuel lines?

So, like the red cube is supported by the in and out fuel lines, or is this problematic?

Yes, and at one point in the past, this was recommended by EI.

RV8JD

Well Known Member

An update. So back at the end of October I posted that the EI FT-60 Red Cube in my RV-8 was still going strong after 1397 Hobbs Hours. So posting that did jinx me after all.

In February the Red Cube failed at 1435 Hobbs Hours. Its mode of death was similar to the OP's. I replaced it with a new one and it has been working fine since.

As a side note, my previous RV-8 has a FloScan 201 and it is still going strong since first flight in 2001 and after about 2375 hours.

In February the Red Cube failed at 1435 Hobbs Hours. Its mode of death was similar to the OP's. I replaced it with a new one and it has been working fine since.

As a side note, my previous RV-8 has a FloScan 201 and it is still going strong since first flight in 2001 and after about 2375 hours.

Last edited:

Draker

Well Known Member

Ideally, we’d be able to see a tear down and failure analysis of a few of these (Not that I’m volunteering). This thread seems to be full of guesses. Has anyone actually torn apart and looked at their failed cube?

It seems ridiculous to me that a device like this would be considered a consumable just because it has a single moving part. Nothing else [EDIT: besides my starter solenoid, hahaha] in my airplane is this fragile.

It seems ridiculous to me that a device like this would be considered a consumable just because it has a single moving part. Nothing else [EDIT: besides my starter solenoid, hahaha] in my airplane is this fragile.

When mine crapped out I ordered another one from ACS. While I was waiting for it I sent an email to the Red Cube guys. They said they would rebuild it for about $200 if I remember. I still have the old one. Maybe I will open it up and look inside.

RV8JD

Well Known Member

DanH took one apart (see pics in this link), but he was commenting on the possibility of a failure blocking fuel flow, not necessarily looking for the failure modes we are seeing.Ideally, we’d be able to see a tear down and failure analysis of a few of these (Not that I’m volunteering). This thread seems to be full of guesses. Has anyone actually torn apart and looked at their failed cube?

It seems ridiculous to me that a device like this would be considered a consumable just because it has a single moving part. Nothing else [EDIT: besides my starter solenoid, hahaha] in my airplane is this fragile.

As a side note, fuel flow is not blocked for a locked rotor, which is stated in the EI FT-60 Red Cube installation instructions.

From the installation instructions:

"Non-Flow Restricting Design (a blocked rotor does not restrict flow)"

It's interesting that it also says this:"Life Expectancy: 10,000 Hrs. Min."

Last edited:

My Floscan 201 has been working issue free over 3,500 flying hours.I have a Floscan 201 that's been giving me issues and I'm currently troubleshooting it with the company. That one says to install it in a 45 degree upslope for bubbles. The picture provided previously here for the Red Cube shows it flat horizontally. What is your experience installing it as I'm most likely going to end up buying a red cube to replace the Floscan if I can't get it working this week?

Daddyman58

Member

Nice install bracket.Another data point: My FT-60 Red Cube has 1397 Hobbs hours on it so far. No problems. (And I hope this post doesn't jinx me!).

Installation pic:

Perhaps you had longevity because yours was level, vs inclined on the motor mount?

Daddyman

RV7 To Go

Well Known Member

The inlet port, outlet port and flow direction are marked on the top of the Red Cube FT-60. This transducer must be suspended between flexable hoses on the inlet and exiting ports. The hoses must be supported within 6 inches of the transducer.

The above was taken from the FT-60 Fuel Flow Transducer Data Sheet 1030032 Rev. I. I wonder if the failure rate is connected to the number of hard mounted installations. Mine was installed as per the instructions and so far, in 7 yrs and 750 hrs, still works accurately.

The above was taken from the FT-60 Fuel Flow Transducer Data Sheet 1030032 Rev. I. I wonder if the failure rate is connected to the number of hard mounted installations. Mine was installed as per the instructions and so far, in 7 yrs and 750 hrs, still works accurately.

Tankerpilot75

Well Known Member

As the old saying goes when it comes to an electrically operated sensor having intermittent or unreliable readings, “first check your ground.” You may have too much resistance or a faulty connection.

Pilot135pd

Well Known Member

Yes, I think my FloScan issue was the fact that the previous owner had it connected to 24v and it worked for a while, which is impressive enough. I ended up installing a Red Cube because I was able to drive to Fort worth and pick it up at Aircraft Spruce the same day and I wanted to install it the next day.My Floscan 201 has been working issue free over 3,500 flying hours.

RV8JD

Well Known Member

Interestingly, those last two sentences underlined above have been added since EI Document No. 1030032 Rev F, dated 7/24/2013, was released, the one that was available when my RV-8 was built. Rev I seems to be the latest version.The inlet port, outlet port and flow direction are marked on the top of the Red Cube FT-60. This transducer must be suspended between flexable hoses on the inlet and exiting ports. The hoses must be supported within 6 inches of the transducer.

The above was taken from the FT-60 Fuel Flow Transducer Data Sheet 1030032 Rev. I. I wonder if the failure rate is connected to the number of hard mounted installations. Mine was installed as per the instructions and so far, in 7 yrs and 750 hrs, still works accurately.

The FloScan 201 in my previous RV-8 (which is still going strong at 2375 hours) is suspended between the flexible input and output hoses.

Last edited: