There are 10^6 threads here about fuel caps, but any suggestions about tightness is buried deep in the text or absent entirely.

RV-7 with stock Usher fuel caps when I bought it. Trying to replace the O-rings, I broke the tab off one of them.

So I bought 2 new ones, had them engraved, etc. But I'm not sure how tight they need to be. Most people I've seen open their fuel caps by digging a screwdriver or something in there, but there are those on VAF who claim they can open them with a pinky. I'd like that. I know one guy who can't get a finger in that little slot, but his caps pop open when he slides a credit card under them. I'd prefer the pinky, but a credit card will do.

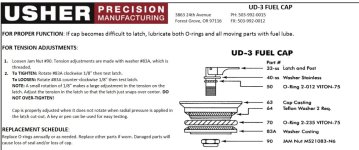

How is tightness properly gauged? I read somewhere (so it must be true) that it should be tight enough that you can't rotate it when it's latched. If it has to be that tight, there's no way I can get it open without a tool. I know how to adjust them, just not how tight to make them.

My only reference is my previous Bonanza, which had similar caps. In that instance, they should always be set up to release easily with finger pressure.

RV-7 with stock Usher fuel caps when I bought it. Trying to replace the O-rings, I broke the tab off one of them.

So I bought 2 new ones, had them engraved, etc. But I'm not sure how tight they need to be. Most people I've seen open their fuel caps by digging a screwdriver or something in there, but there are those on VAF who claim they can open them with a pinky. I'd like that. I know one guy who can't get a finger in that little slot, but his caps pop open when he slides a credit card under them. I'd prefer the pinky, but a credit card will do.

How is tightness properly gauged? I read somewhere (so it must be true) that it should be tight enough that you can't rotate it when it's latched. If it has to be that tight, there's no way I can get it open without a tool. I know how to adjust them, just not how tight to make them.

My only reference is my previous Bonanza, which had similar caps. In that instance, they should always be set up to release easily with finger pressure.