Pilot135pd

Well Known Member

I think my previous thread was deleted because it sent members to a YouTube video I uploaded there. We've all heard a picture is worth a thousand words and I think a video is worth ten times more. It was the only way for me to explain the problem I had with my alternator.

Thank you to all who gave me suggestions on what to do. Sadly the 2 year old I had hired to help me rebuild the alternator was on time-out today and her parents didn't let her help me, so I removed the cooling shroud and noticed that if I pull that bolt up it locks in place so I'm hoping that any wire connected to it is actually connected to something like an eye ring and when the bolt is locked in place it makes the connection. I bought the extra nuts needed to install it correctly.

I'll know more once I install and test it this weekend. If it doesn't work, or works intermittently, then I'll follow Bill's advice and just take it to the local alternator shop and have them reattach the wire correctly, if the 2 year old isn't available

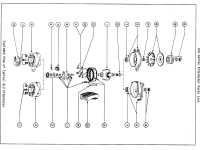

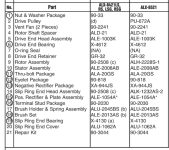

Bill, this is the model

Thank you to all who gave me suggestions on what to do. Sadly the 2 year old I had hired to help me rebuild the alternator was on time-out today and her parents didn't let her help me, so I removed the cooling shroud and noticed that if I pull that bolt up it locks in place so I'm hoping that any wire connected to it is actually connected to something like an eye ring and when the bolt is locked in place it makes the connection. I bought the extra nuts needed to install it correctly.

I'll know more once I install and test it this weekend. If it doesn't work, or works intermittently, then I'll follow Bill's advice and just take it to the local alternator shop and have them reattach the wire correctly, if the 2 year old isn't available

Bill, this is the model