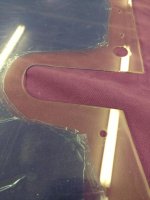

For years now, I've read about canopy cracks. For a while, we were all convinced that it was an installation problem (screws versus rivets/deburr better/ polish all the edges/sikaflex was the answer) but then, years later, we're still seeing cracks and lots of them. We also blame temperature changes but they still crack even in fairly mild temps. I just read where a Todds canopy mysteriously cracked while sitting on the ground. A buddy of mine recently taxiied his RV-8 in the grass (fairly rough) and came back two days later and there are multiple cracks. In my opinion, something else, perhaps in combination with all of the above, is at work. One thing I've observed is that many of us jack our airplanes one side at a time for tire changes, brake or bearing work. . Is it possible that if we're doing that with the canopy closed, we are applying a slight twist to the canopy that could cause micro-cracks that could, I repeat could, later develop into big cracks when presented with the above build and environmental conditions? The cracks on my friend's 8 are very similar to the most recently reported cracks and are on opposite sides of the canopy. They all occurred simultaneously, while sitting on the ground. I can honestly say that I don't recall ever moving my canopy while its on the jack so I can't say for sure if there was any additional resistance indicating it was in a bind. My canopy is usually open during maintenance.

Last edited: