Desert Rat

Well Known Member

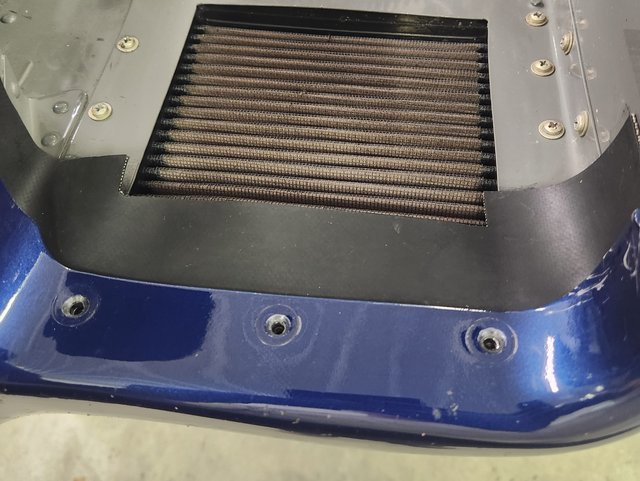

This is with regard to the gap between the fwd edge of the baffle ramps and the lower cowl inlet aft edge; I understand that there needs to be a gap there because the baffle material gets fastened to the under side of the cowl lip and then laps up onto the surface of the baffle ramp to bridge the gap between the two.

But how big is that gap? It obviously needs to be big enough that I can get the baffle rubber tucked up in there while installing the cowl, but what distance works well for that?

But how big is that gap? It obviously needs to be big enough that I can get the baffle rubber tucked up in there while installing the cowl, but what distance works well for that?