PandaCub

Active Member

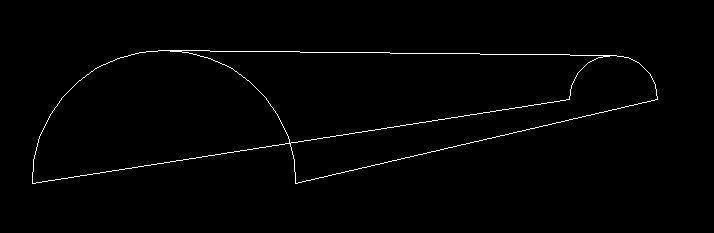

While preflighting my RV-8 yesterday I noticed a brand new 8" crack on the starboard side of my Todd's tinted canopy. No obvious rhyme or reason as to why it occurred.

This makes two major cracks (first one documented here) and I'm wondering what to do now.

I am not the builder but I assume he used SikaFlex; from the photo, however, you can see the crack propagated from the joint up and there seems to be little "flex" to this material.

A new canopy from Van's is $1700 + shipping + the pain of fitting it to my existing frame. I'd prefer a repair, but don't know if that would simply be a band-aid. In the meantime, I've stopped drilled the crack and covered it with both aluminum and duct tape.

Any suggestions appreciated. I've seen the name Dan Kintar referenced as a possible canopy guru, but can't seem to find his contact info.

This makes two major cracks (first one documented here) and I'm wondering what to do now.

I am not the builder but I assume he used SikaFlex; from the photo, however, you can see the crack propagated from the joint up and there seems to be little "flex" to this material.

A new canopy from Van's is $1700 + shipping + the pain of fitting it to my existing frame. I'd prefer a repair, but don't know if that would simply be a band-aid. In the meantime, I've stopped drilled the crack and covered it with both aluminum and duct tape.

Any suggestions appreciated. I've seen the name Dan Kintar referenced as a possible canopy guru, but can't seem to find his contact info.