Condor

Member

I’ve built my RV14 as per the plans firewall forward which means that I have the vent fitted on the right hand forward inlet ramp to direct air to the heater muffs on the exhaust. This is standard for the non EXP119 IO-390.

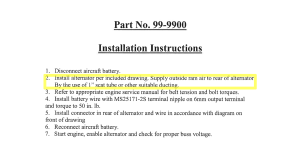

I haven’t fitted a cooling blast tube for the Plane Power alternator and wondering if I should modify the inlet ramp to accept a second takeoff point for a blast tube.

What have others done? I’ve only 20 hours on the aircraft at this stage and hoping for a reasonable lifespan for the alternator.

Thanks in anticipation for any replies.

Ian

RV14A EI-XIV.

I haven’t fitted a cooling blast tube for the Plane Power alternator and wondering if I should modify the inlet ramp to accept a second takeoff point for a blast tube.

What have others done? I’ve only 20 hours on the aircraft at this stage and hoping for a reasonable lifespan for the alternator.

Thanks in anticipation for any replies.

Ian

RV14A EI-XIV.