Hartstoc

Well Known Member

Now that we are getting comfortable flying “electron-dependent” aircraft and have powerful, lightweight lithium batteries at our disposal, I’ve been thinking it is time to find a way to SAFELY eliminate one of the last vestiges of the magneto era- the engine driven mechanical fuel pump. There are a lot of really good reasons for doing this that I won’t go into here, but the challenge in making it possible is to find a reliable electric fuel pump properly matched to the task. This thread documents my successful search supported by real data, and I’ve generated accurate performance charts under real-world conditions for three pumps.

Thousands of airplanes already sport electric boost pumps that seem to work well, but on close examination few of them make any sense at all in this context.Two problems with most pumps currently in use is that they generate flow and consume power FAR IN EXCESS of our needs, and many feature continuous short-loop recirculation of the vast majority of their output back to the pump inlet. This is no big deal for backup pumps used intermittently, but wholly ill-suited to continuous operation in a twin-pump setup with no engine driven pump. Some are also quite heavy, bad news with two installed. For continuous operation, return lines to the tank in use become mandatory, and the pump must operate efficiently to minimize electrical demand in normal operation and maximize range on battery power should the alternator fail.

A plethora of choices exist in the 500-1,000 HP range for auto racing applications, but precious few really make sense in the context of typical RV’s. Also, I’ve discovered that published performance data for pumps is often not detailed, accurate, and reliable enough to allow intelligent selection, and these do not take into account system-wide resistance that must be subtracted from the performance of the unrestricted pump.

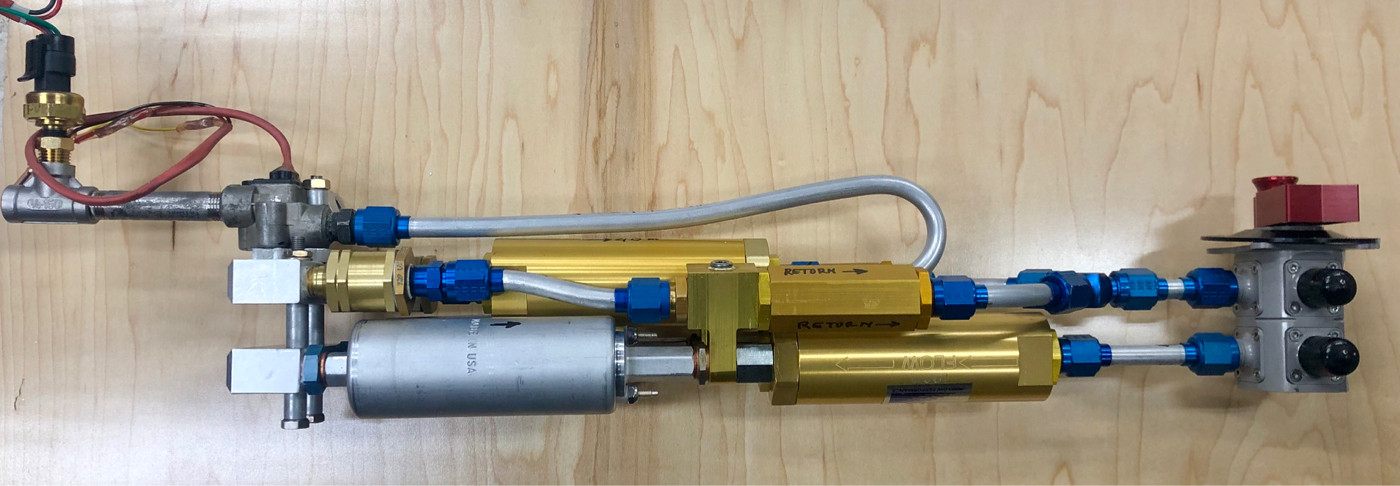

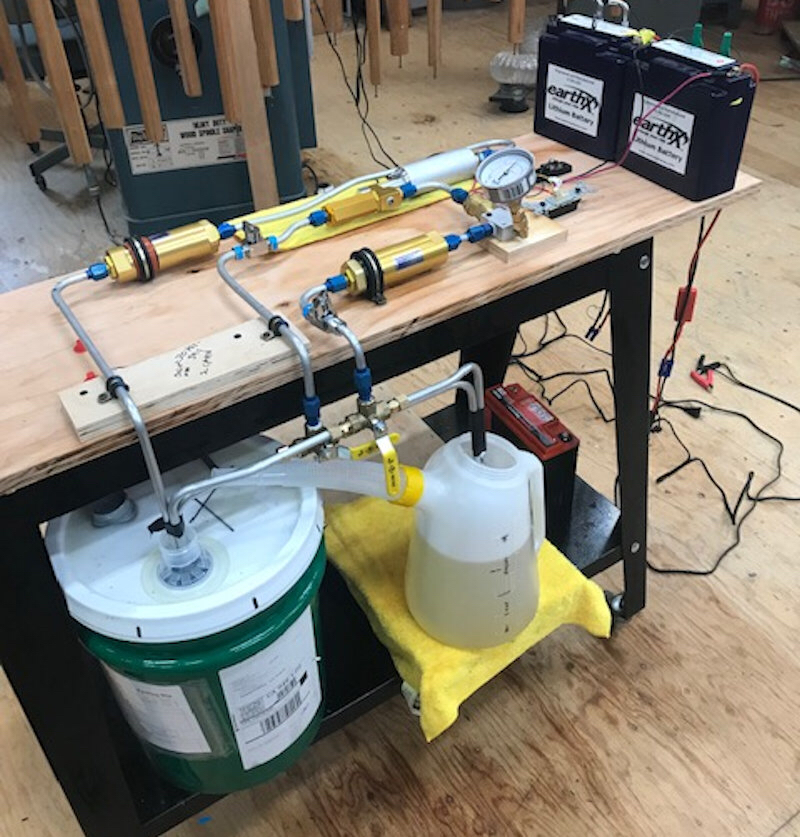

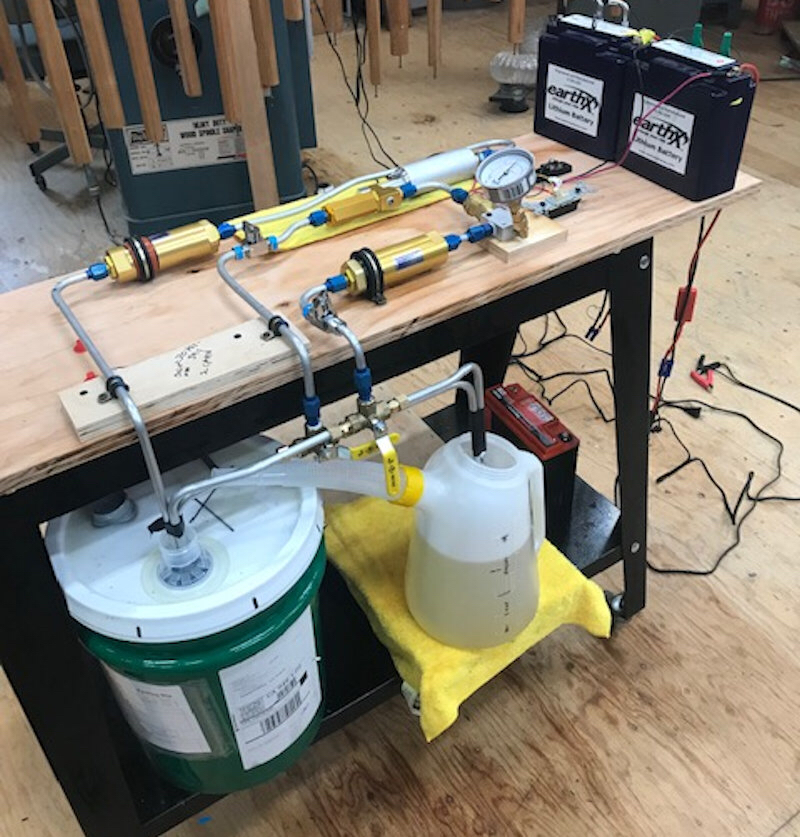

I decided to build this test rig, shown here collecting data for one of the Walbro pumps. It incorporates pre- and post-pump filters and enough lift, bends, turns, and manifold reversals to roughly mimic the aft-of-firewall dynamic flow restrictions of a typical RV installation. Here, the return line is closed off, and “engine” output, dialed-in at 30PSI resistance, is being shunted to the flow-measuring vessel.

Here you can see the right side valve shunting output to the measuring vessel. The black marks were established using a precision flask, and the flow would be fully stabilized by the time the stopwatch was started at the bottom mark.

I did thorough dynamic testing of three pumps and used the raw data to generate the three Excel performance charts below, testing each pump at 10PSI intervals from 0-60PSI(increased to 5PSI intervals within my operating range of 20-40PSI). The rig allows precise stopwatch timing of exactly one gallon of fluid at each pressure point. It features 3-way valves to shunt the output return line flow and/or “engine” flow into a measuring vessel or back to the source tank. The return line output was blocked completely for GPH vs. Pressure testing, but I also measured pressure and return-line GPH for each pump with the “engine” flow blocked completely to mimic pre-start operation of the pump.

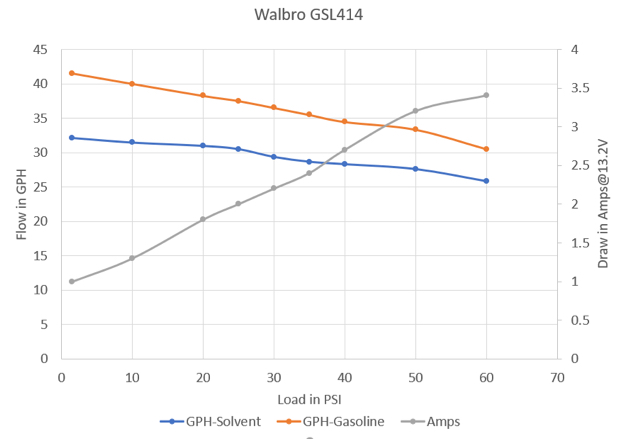

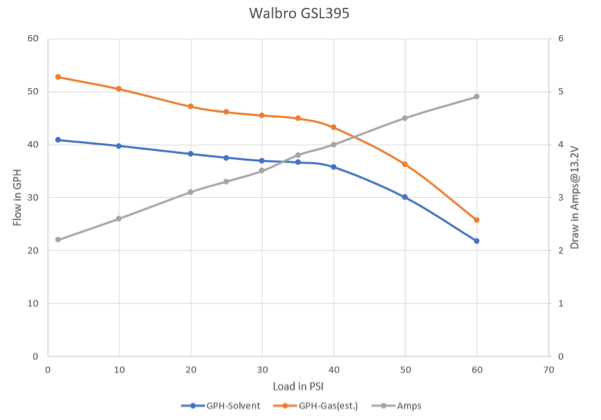

My system will be Bendix-type FI from Airflow Performance, tolerant of wide swings in system pressure, so each pump on my RV will be equipped with simple external pressure-relief valves outputting to return lines(instead of a more sophisticated pressure regulators needed for EFI) and large external check valves, so the rig features those as well. I’ll say more about my experience with the very interesting dynamic behavior of these relief valves in a later post in this thread. Stoddard solvent, a form of mineral sprits, is generally used as a safer alternative to gasoline for these tests, but I went a step further and found an even safer soy-based solvent substitute. After Collecting complete data for all three pumps using this solvent, which has a similar viscosity to diesel fuel, did a carefully grounded calibration run with gasoline on the winning pump at 30PSI to validate my results. Somewhat shocked by the increased flows with gasoline, I ended up repeating the entire test series for the winning pump using gasoline(while constantly purging the airspace in both vessels with Argon!). You will see two output curves for each pump, the lower for the solvent tests, and the upper for gasoline. For the top chart, every data point on all curves was collected directly. For the bottom pump, I did three data points with Gasoline and saw the same relationship as with the first, and was able to derive correction criteria for the remaining points on the gasoline curve. For the middle chart, the entire gasoline curve was generated using correction criteria.

Finally, I decided to dismantle each pump tested to compare design and construction- some photos and discussion will follow in a later post in this thread.(edit note 2-17-19: I tried to add this info here but exceeded the allowable post word-count. Please see the post on page three of this thread where I’ve added photos and commentary- O.H.)

Happily, a very clear winner emerged for RV’s between 125 and 300HP, the Walbro GSL414, with results shown in the first graph. Note that it generates a reliable flow of more than 35GPH at all pressures below 40PSI, and consumes less than [email protected] through the 25-35PSI range that my RV will operate within. Even this output is far in excess of our needs up to about 300HP, but power required is so low that ONE of my twin EarthX ETX900-VNT’s will operate one of these pumps and a LightSpeed PlasmaIII through an entire 40-gallon fuel load!

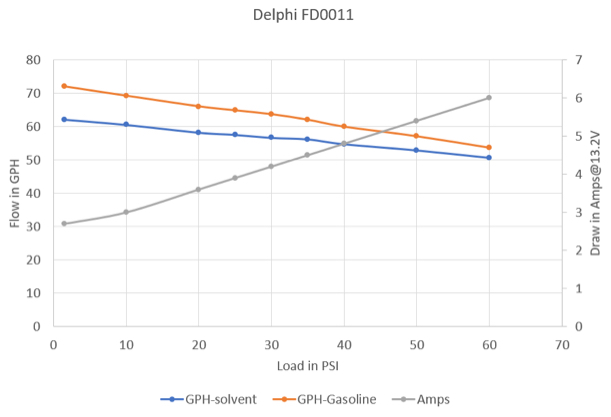

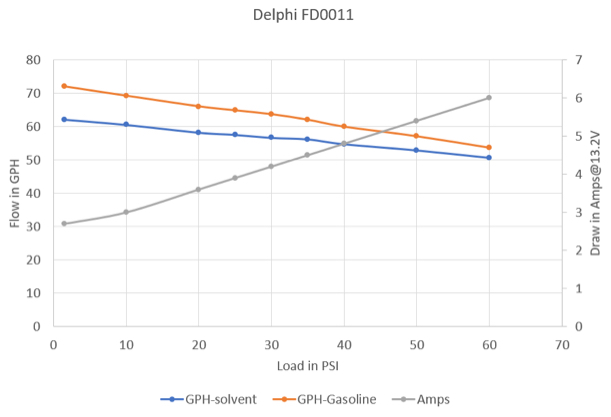

Compare that with the absurdly high output and consumption of the Delphi from AP depicted in the third graph. All that surplus output pumped back through the return lines is wasted energy. At 795grams, the all-steel Deplhi also weighs nearly twice as much as the 454gram aluminum-body Walbro GSL’s.

I already feel well rewarded for the effort and dollars invested in this study, and I hope some of you find it useful as well.- Otis

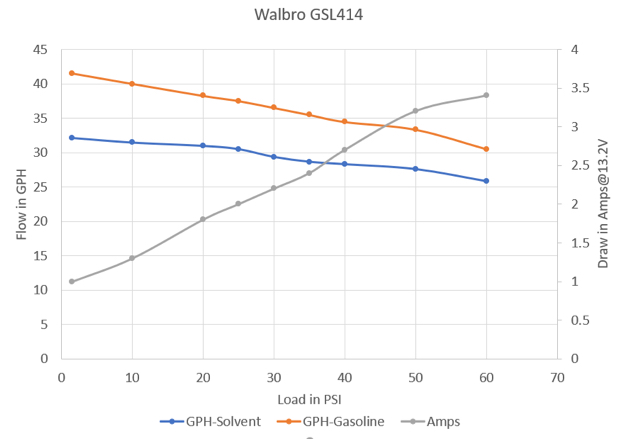

And the winner is!: the Walbro GSL414

This pump pushes [email protected] through the return lines drawing [email protected] sitting idle at pre-start!

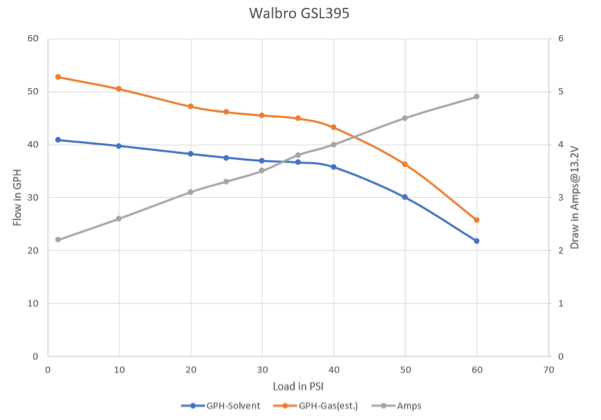

The Walbro GSL395 was also tested, but proved less efficient.

Here are results from the Delphi pump obtained from AP:

Pushes fully 62GPH@33 PSI drawing 4.2Amps @13.2V sitting idle pre-start. The flow from this pump was actually frightening to witness with gasoline.

This is getting long, so I’ll save photos and discussion of the disassembled pumps for a later post in this thread.

Notes: the ammeter used was placed in series with my trusty Flukemeter, and reported parallel to #but 1/0th of an Amp lower than the Fluke across a 1-6Amp range. Voltage agrees perfectly.

Here iare links to parts one and two of this series:

http://www.vansairforce.com/community/showthread.php?t=167848&highlight=Anatomy

http://www.vansairforce.com/community/showthread.php?t=167848&highlight=Anatomy

Finally, I want to thank Ross Farnham at SDS for suggesting the GSL414 and for serving as my sounding board in many emails during this work-

Thousands of airplanes already sport electric boost pumps that seem to work well, but on close examination few of them make any sense at all in this context.Two problems with most pumps currently in use is that they generate flow and consume power FAR IN EXCESS of our needs, and many feature continuous short-loop recirculation of the vast majority of their output back to the pump inlet. This is no big deal for backup pumps used intermittently, but wholly ill-suited to continuous operation in a twin-pump setup with no engine driven pump. Some are also quite heavy, bad news with two installed. For continuous operation, return lines to the tank in use become mandatory, and the pump must operate efficiently to minimize electrical demand in normal operation and maximize range on battery power should the alternator fail.

A plethora of choices exist in the 500-1,000 HP range for auto racing applications, but precious few really make sense in the context of typical RV’s. Also, I’ve discovered that published performance data for pumps is often not detailed, accurate, and reliable enough to allow intelligent selection, and these do not take into account system-wide resistance that must be subtracted from the performance of the unrestricted pump.

I decided to build this test rig, shown here collecting data for one of the Walbro pumps. It incorporates pre- and post-pump filters and enough lift, bends, turns, and manifold reversals to roughly mimic the aft-of-firewall dynamic flow restrictions of a typical RV installation. Here, the return line is closed off, and “engine” output, dialed-in at 30PSI resistance, is being shunted to the flow-measuring vessel.

Here you can see the right side valve shunting output to the measuring vessel. The black marks were established using a precision flask, and the flow would be fully stabilized by the time the stopwatch was started at the bottom mark.

I did thorough dynamic testing of three pumps and used the raw data to generate the three Excel performance charts below, testing each pump at 10PSI intervals from 0-60PSI(increased to 5PSI intervals within my operating range of 20-40PSI). The rig allows precise stopwatch timing of exactly one gallon of fluid at each pressure point. It features 3-way valves to shunt the output return line flow and/or “engine” flow into a measuring vessel or back to the source tank. The return line output was blocked completely for GPH vs. Pressure testing, but I also measured pressure and return-line GPH for each pump with the “engine” flow blocked completely to mimic pre-start operation of the pump.

My system will be Bendix-type FI from Airflow Performance, tolerant of wide swings in system pressure, so each pump on my RV will be equipped with simple external pressure-relief valves outputting to return lines(instead of a more sophisticated pressure regulators needed for EFI) and large external check valves, so the rig features those as well. I’ll say more about my experience with the very interesting dynamic behavior of these relief valves in a later post in this thread. Stoddard solvent, a form of mineral sprits, is generally used as a safer alternative to gasoline for these tests, but I went a step further and found an even safer soy-based solvent substitute. After Collecting complete data for all three pumps using this solvent, which has a similar viscosity to diesel fuel, did a carefully grounded calibration run with gasoline on the winning pump at 30PSI to validate my results. Somewhat shocked by the increased flows with gasoline, I ended up repeating the entire test series for the winning pump using gasoline(while constantly purging the airspace in both vessels with Argon!). You will see two output curves for each pump, the lower for the solvent tests, and the upper for gasoline. For the top chart, every data point on all curves was collected directly. For the bottom pump, I did three data points with Gasoline and saw the same relationship as with the first, and was able to derive correction criteria for the remaining points on the gasoline curve. For the middle chart, the entire gasoline curve was generated using correction criteria.

Finally, I decided to dismantle each pump tested to compare design and construction- some photos and discussion will follow in a later post in this thread.(edit note 2-17-19: I tried to add this info here but exceeded the allowable post word-count. Please see the post on page three of this thread where I’ve added photos and commentary- O.H.)

Happily, a very clear winner emerged for RV’s between 125 and 300HP, the Walbro GSL414, with results shown in the first graph. Note that it generates a reliable flow of more than 35GPH at all pressures below 40PSI, and consumes less than [email protected] through the 25-35PSI range that my RV will operate within. Even this output is far in excess of our needs up to about 300HP, but power required is so low that ONE of my twin EarthX ETX900-VNT’s will operate one of these pumps and a LightSpeed PlasmaIII through an entire 40-gallon fuel load!

Compare that with the absurdly high output and consumption of the Delphi from AP depicted in the third graph. All that surplus output pumped back through the return lines is wasted energy. At 795grams, the all-steel Deplhi also weighs nearly twice as much as the 454gram aluminum-body Walbro GSL’s.

I already feel well rewarded for the effort and dollars invested in this study, and I hope some of you find it useful as well.- Otis

And the winner is!: the Walbro GSL414

This pump pushes [email protected] through the return lines drawing [email protected] sitting idle at pre-start!

The Walbro GSL395 was also tested, but proved less efficient.

Here are results from the Delphi pump obtained from AP:

Pushes fully 62GPH@33 PSI drawing 4.2Amps @13.2V sitting idle pre-start. The flow from this pump was actually frightening to witness with gasoline.

This is getting long, so I’ll save photos and discussion of the disassembled pumps for a later post in this thread.

Notes: the ammeter used was placed in series with my trusty Flukemeter, and reported parallel to #but 1/0th of an Amp lower than the Fluke across a 1-6Amp range. Voltage agrees perfectly.

Here iare links to parts one and two of this series:

http://www.vansairforce.com/community/showthread.php?t=167848&highlight=Anatomy

http://www.vansairforce.com/community/showthread.php?t=167848&highlight=Anatomy

Finally, I want to thank Ross Farnham at SDS for suggesting the GSL414 and for serving as my sounding board in many emails during this work-

Last edited: