rv12is

Active Member

I'm getting ready to crimp some d-sub pins and have two crimpers to choose from. I'm not sure which crimper is the better option. So I crimped two test pins and examined them under the microscope. Despite the two crimpers looking very similar, the resulting crimps are definitely different.

Which crimper would you choose? A or B? Is either acceptable? Or neither?

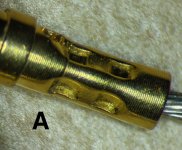

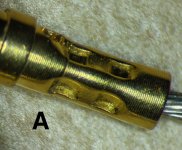

Crimp A:

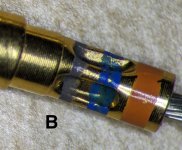

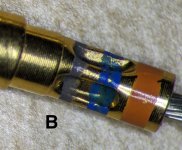

Crimp B:

Which crimper would you choose? A or B? Is either acceptable? Or neither?

Crimp A:

Crimp B: