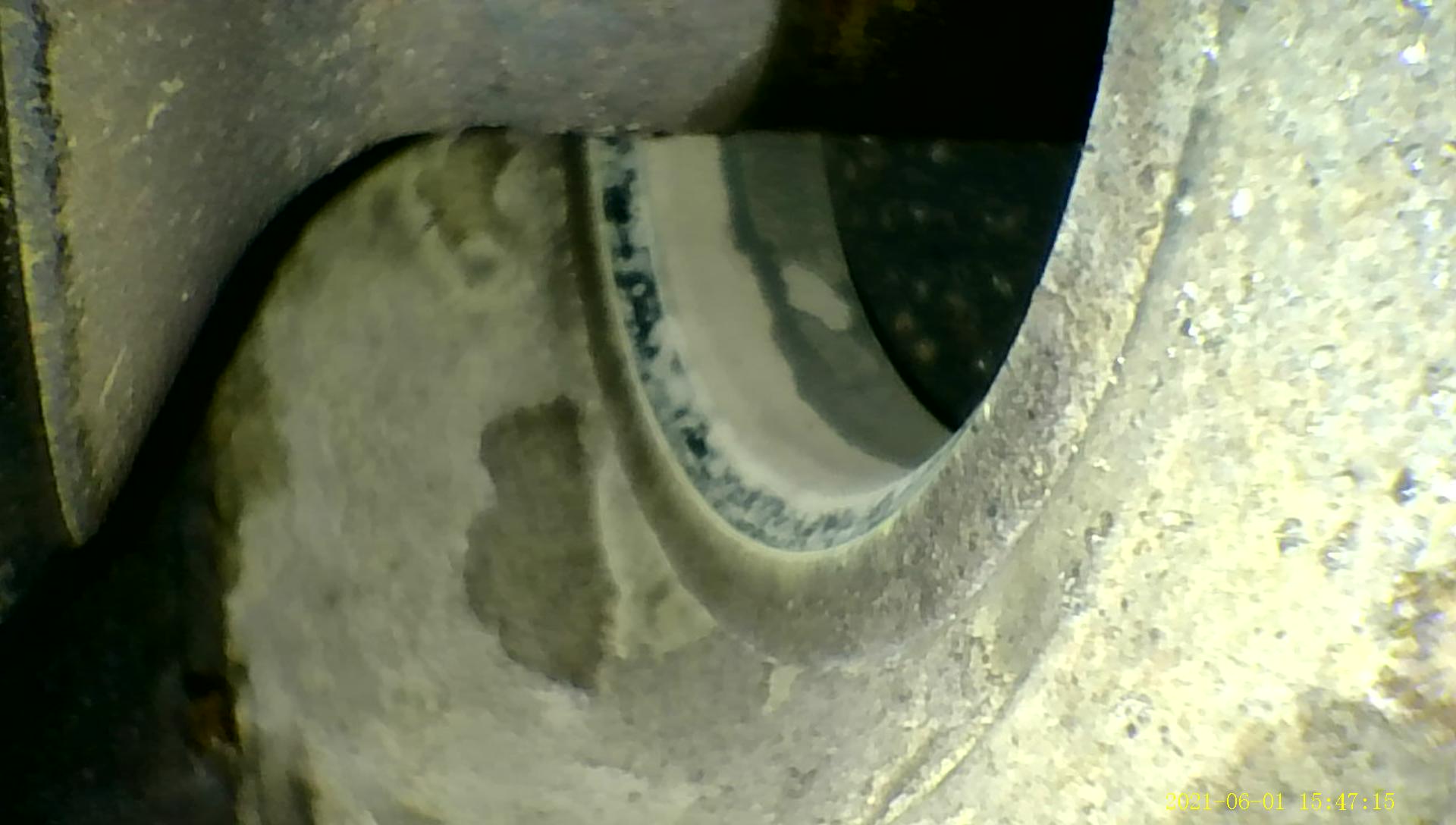

Fired up the O-360 in our RV-6A last week and it ran rough, with EGT in the #3 cylinder failing to come up. Shut down the engine and pulled the plugs - they looked find. Then, a compression test and we could clearly hear air entering the exhaust system. Bought an inexpensive borescope, and the following are video clips and images of the exhaust valve in question. I've not analyzed borescope imagery before and could use some help with what these show. I'm reading everything I can find on leaky exhaust valves and ordered a valve guide reamer from McFarlane in case this is a stuck valve. I'm also looking into lapping the valve in place since it appears to me (remember I've never done this before) that there is significant pitting on the valve and the seat.

Help!

youtu.be/D9OgOrHm-xg

youtu.be/5etTaez_qoA

Help!

youtu.be/D9OgOrHm-xg

youtu.be/5etTaez_qoA