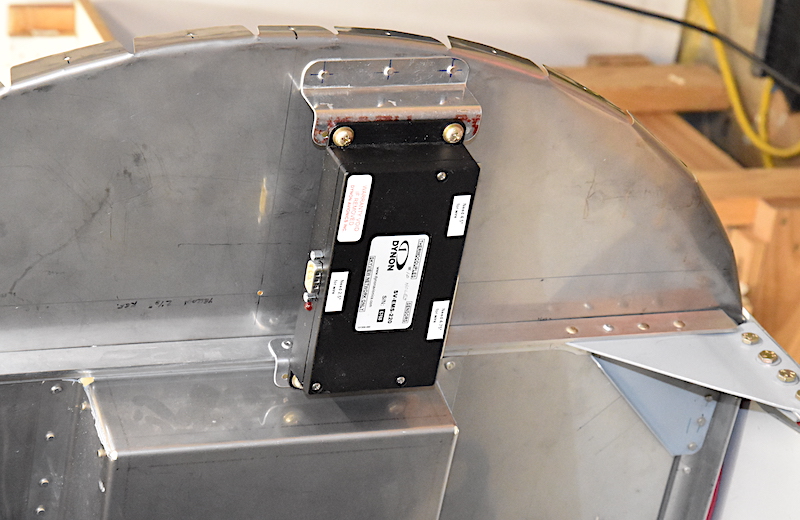

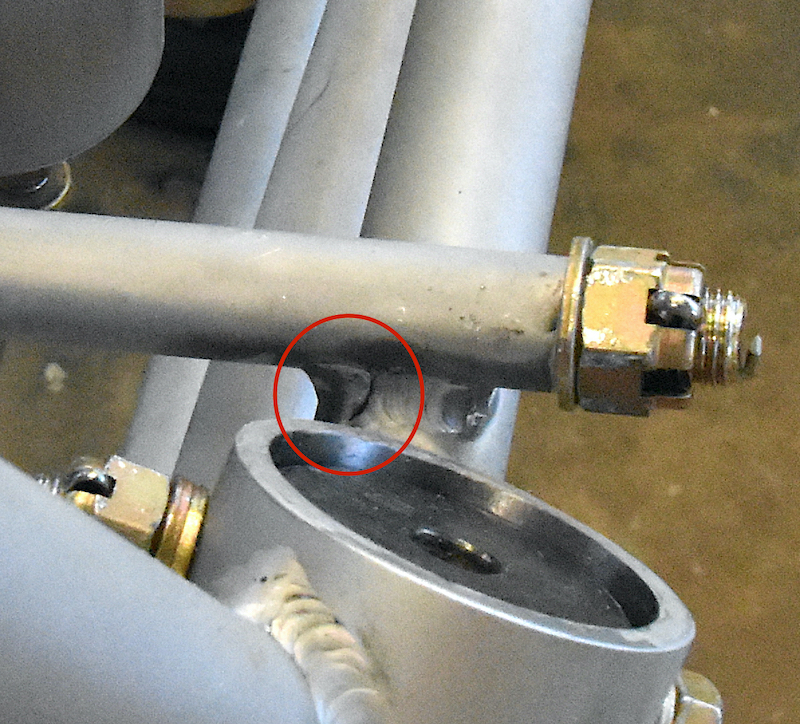

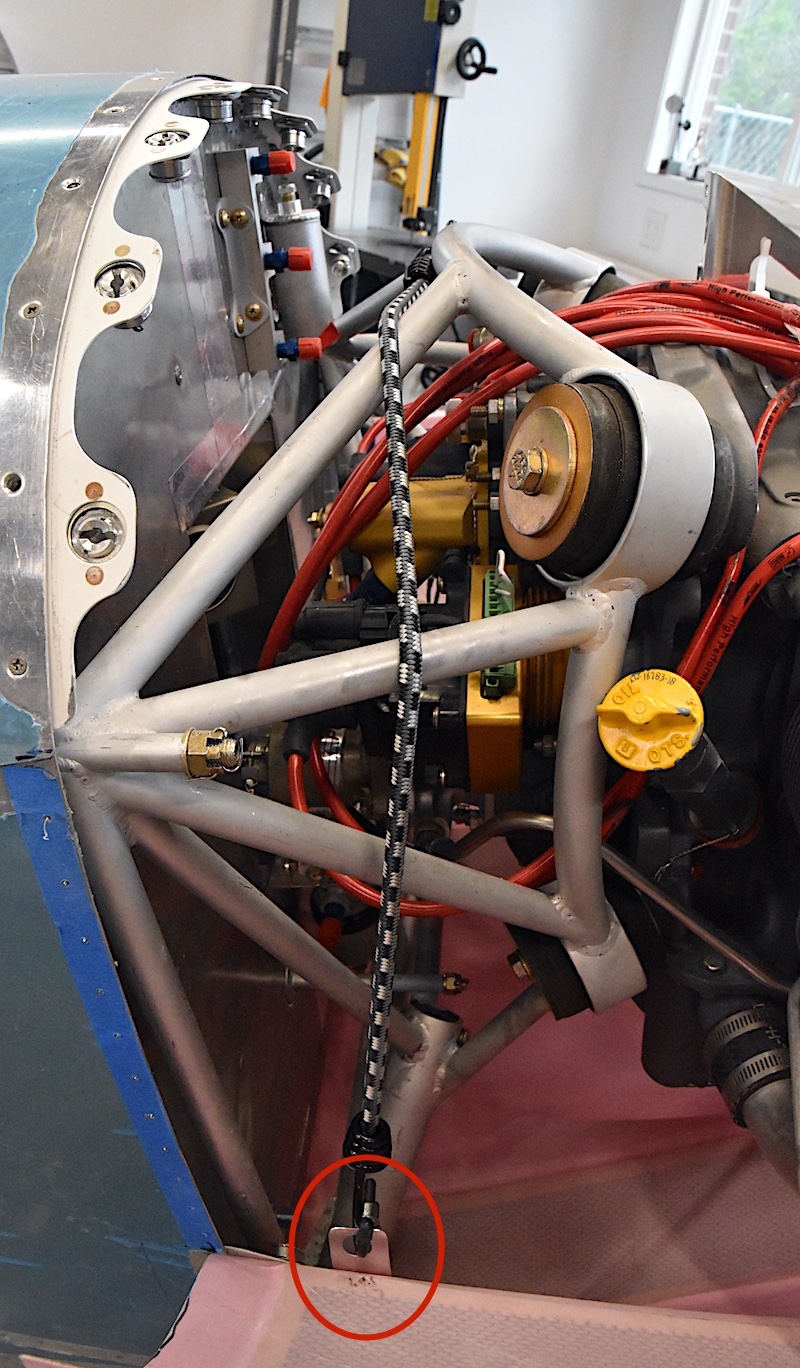

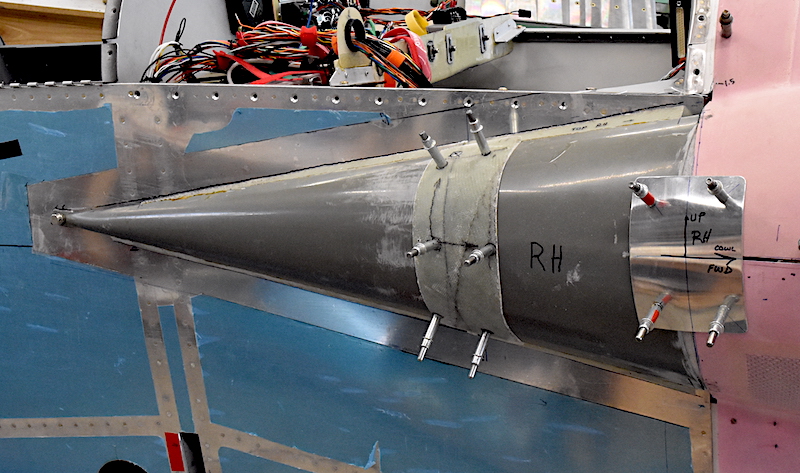

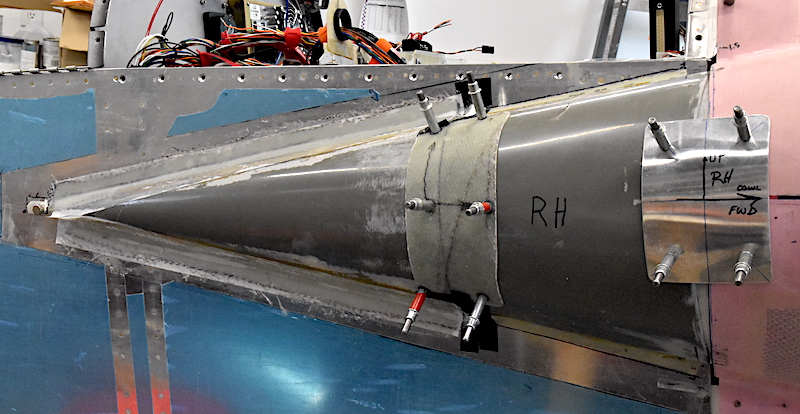

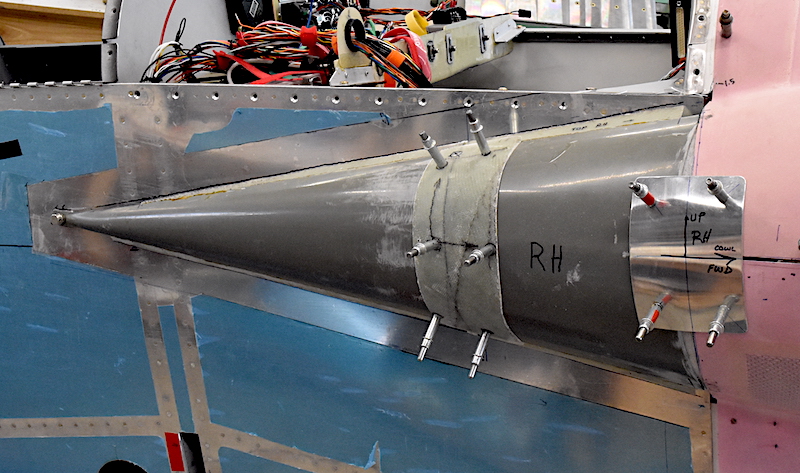

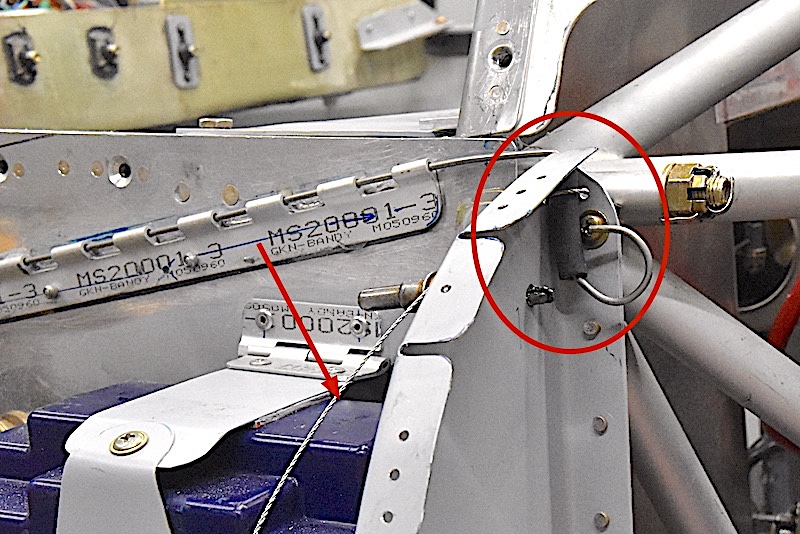

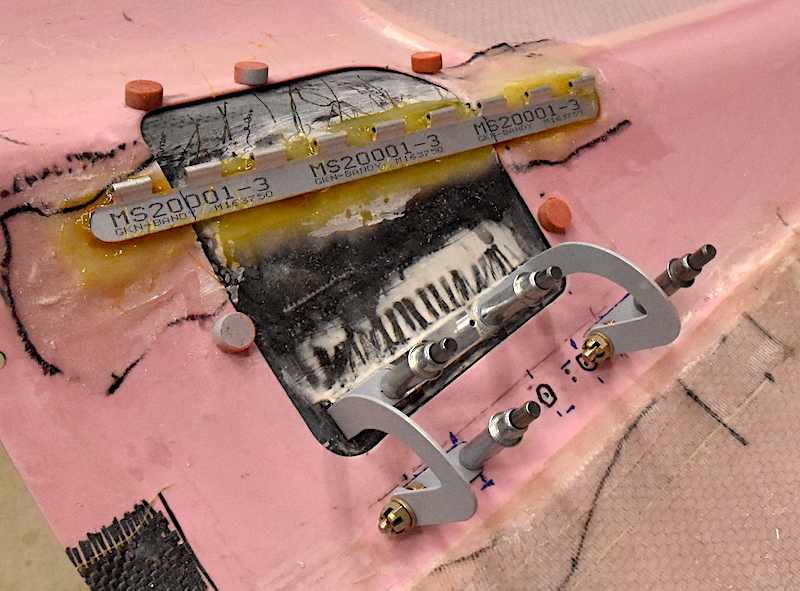

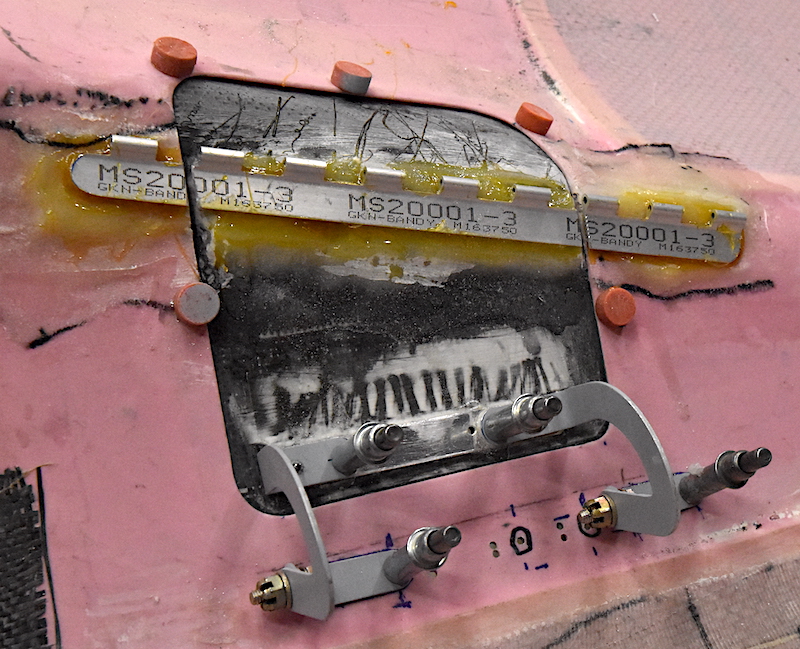

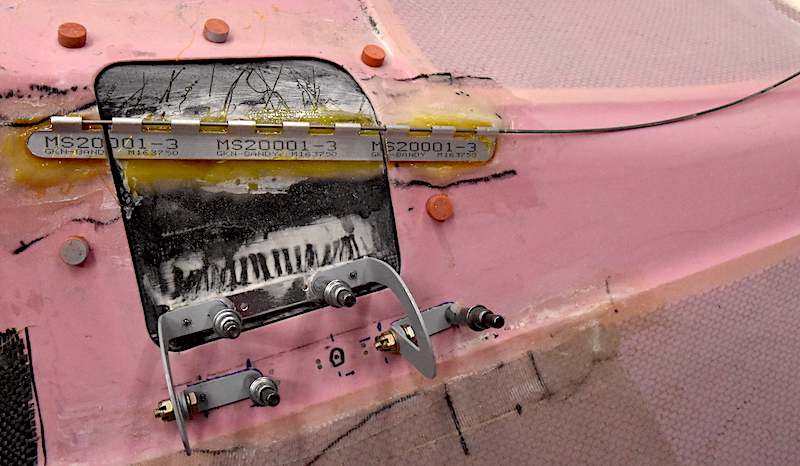

The small weld issue mentioned above is an incomplete weld. It had the appearance of a crack but wasn’t, exactly.

I’m an old aerospace engineer and have done many crack propagation analyses, and felt it needed to be repaired.

Checked with my ferried airplane’s AI, who said to repair it. So did my mentor, another engineer, and Van’s support. Actually Support said that this area might crack anyway at some point, repaired or not, but that it would be better to repair it.

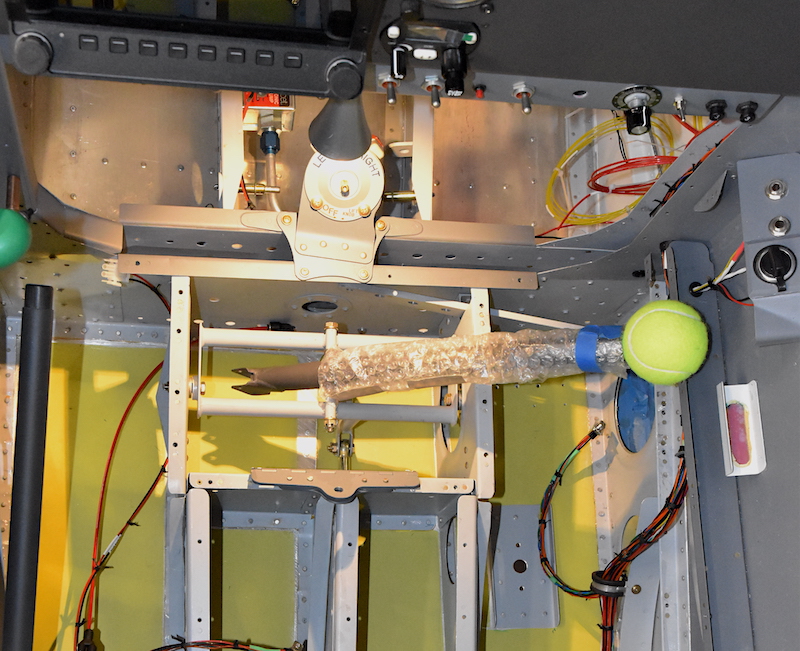

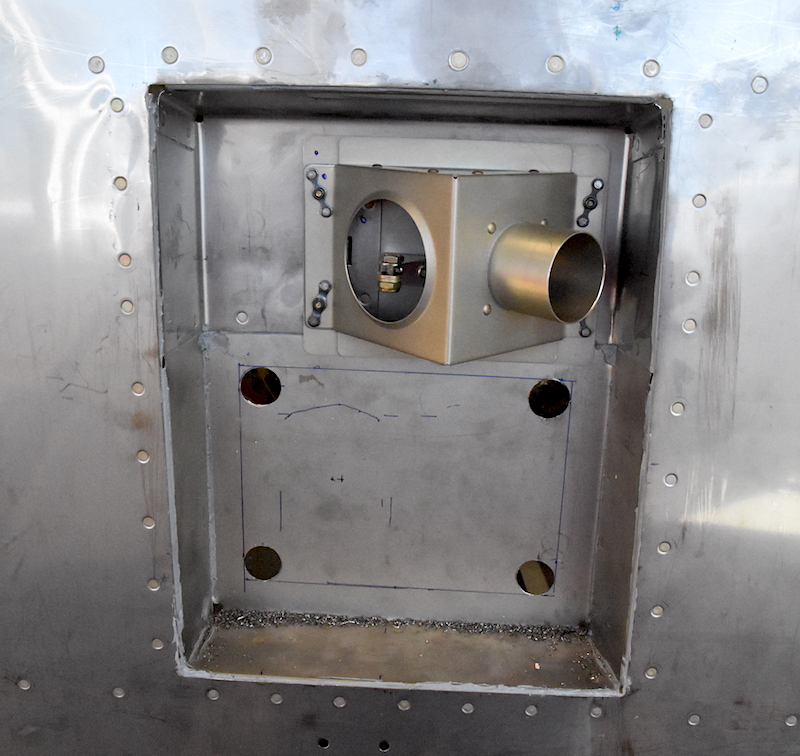

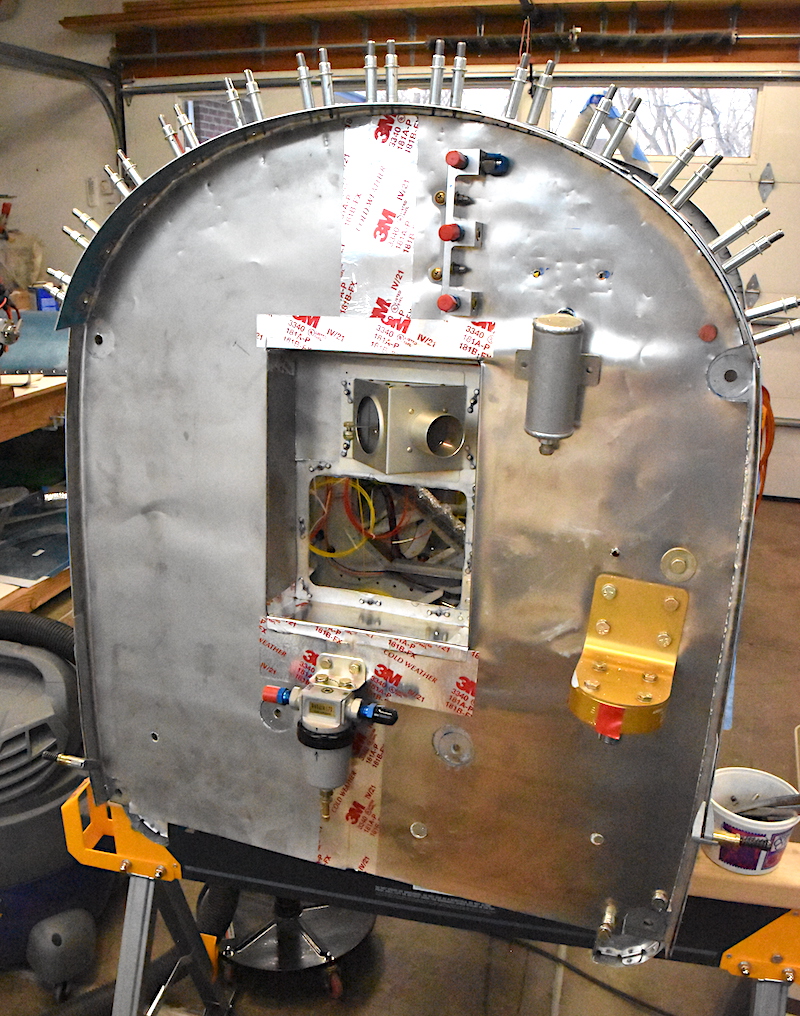

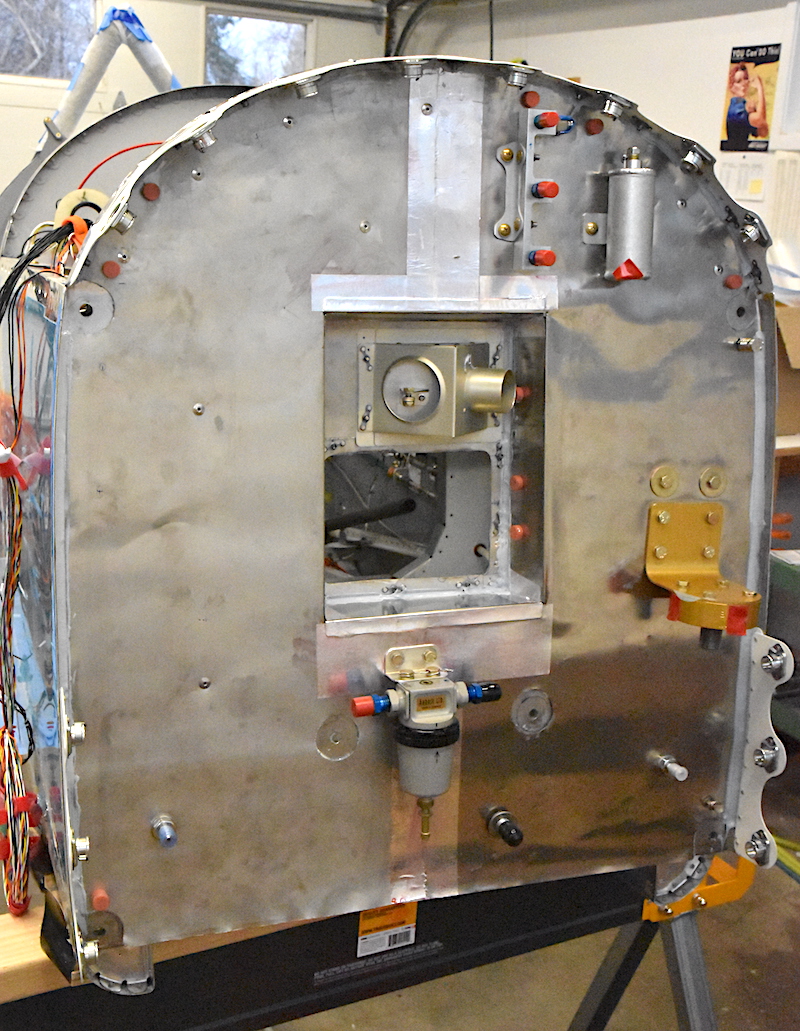

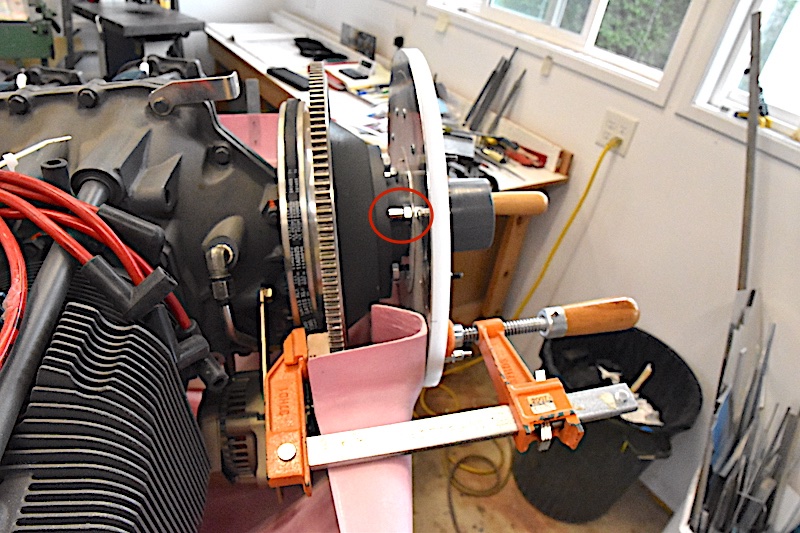

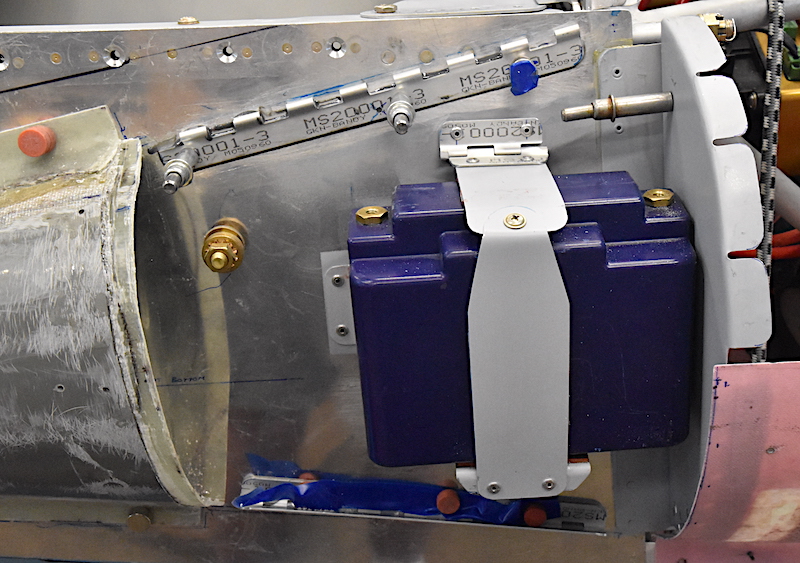

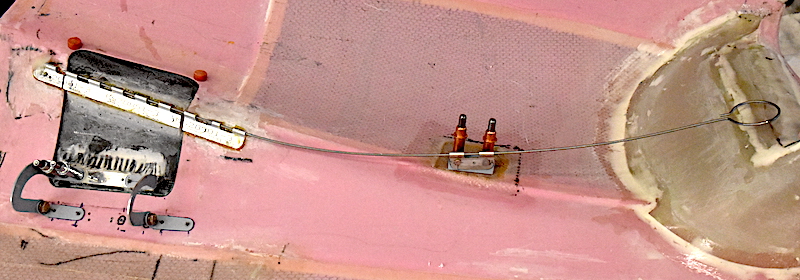

It’s at the top of the right landing gear socket and is in that red circle.

After pulling the landing gear legs off and removing the engine mount from the fuselage (which I hated to do….) I removed the cadmium plating in that area with Muriatic acid. Some of you will cringe at this, but I did it in the kitchen sink, it being way too windy to attempt it outside. The stainless steel sink wasn’t affected by the few drops of acid that landed on it, and with the faucet going, there was ready dilution. My exhaust fan vents outside and is unusually powerful. I opened a window and got positioned so that the flow was window to me to sink to fan, and I was in clean air.

After an hour, the plating was gone in that area. The actual welding took no more than two minutes. I put primer over the non-plated areas, bolted it back to the firewall and reinstalled the landing gear. Done.

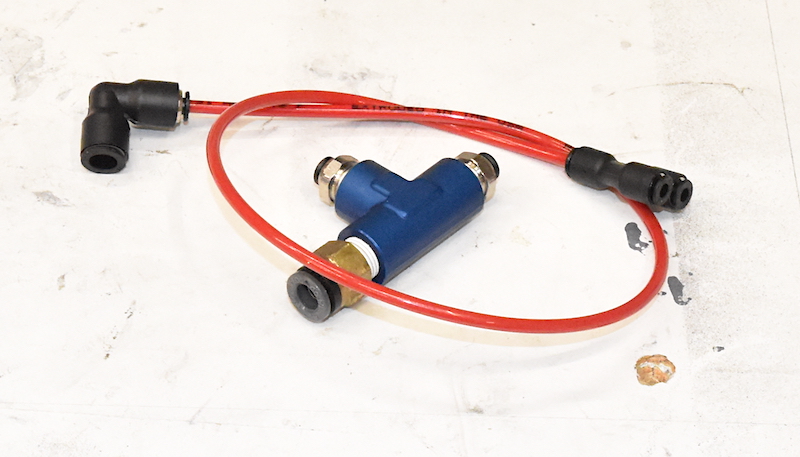

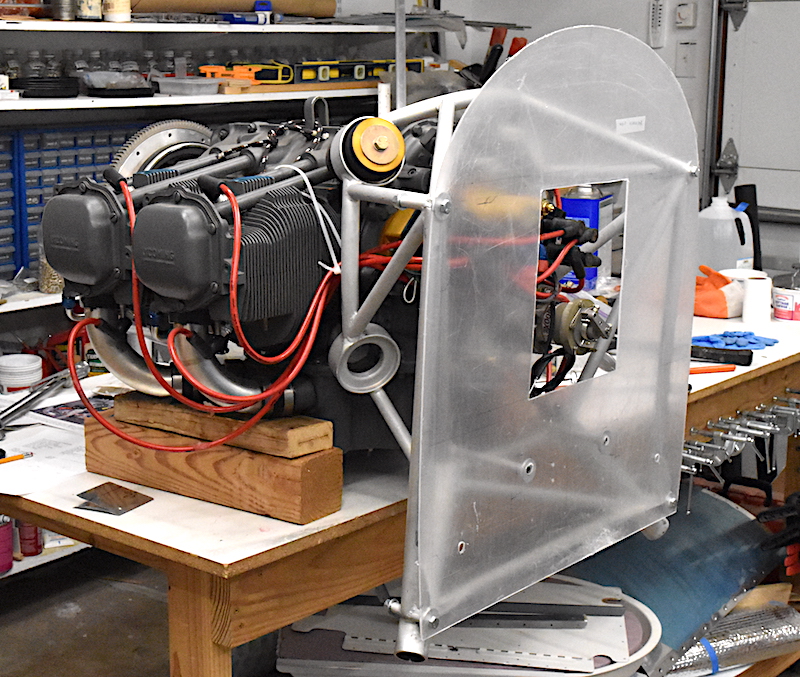

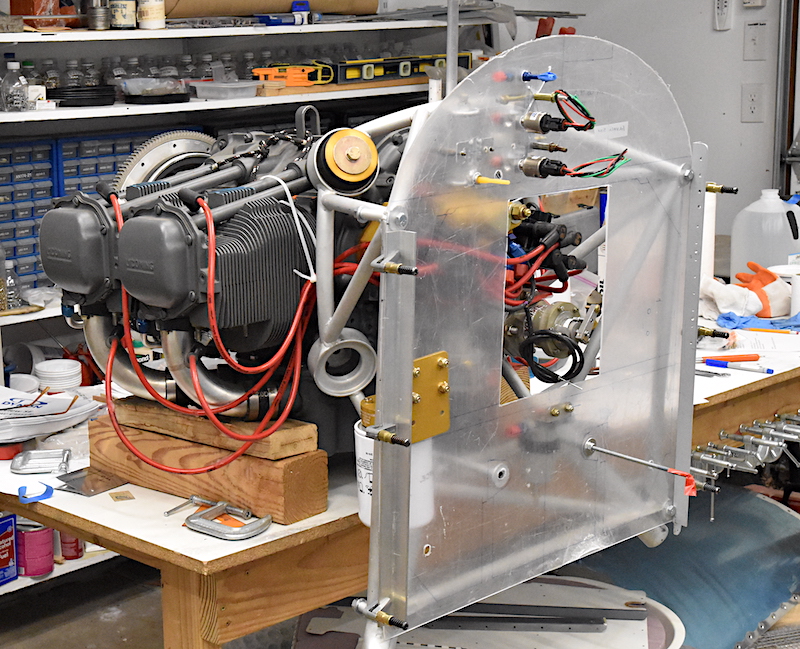

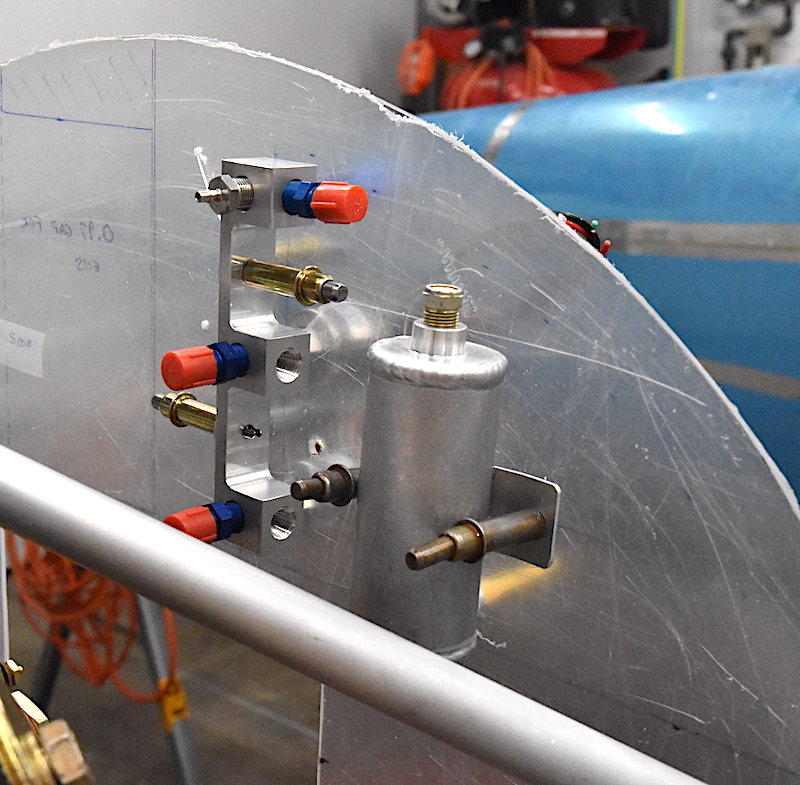

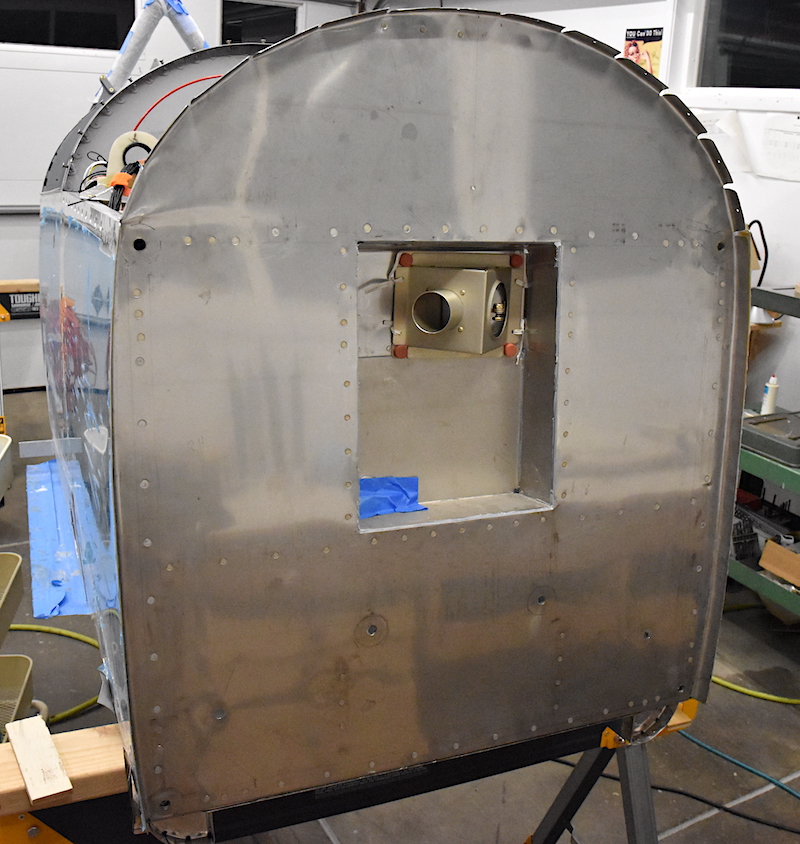

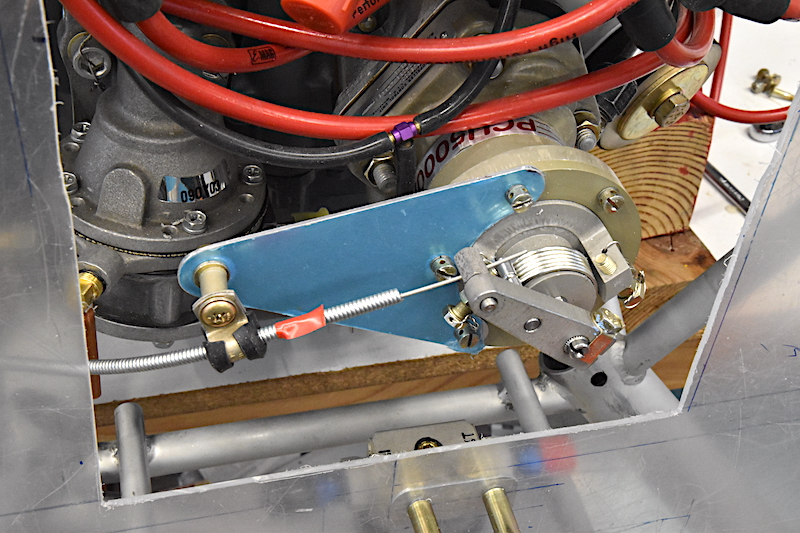

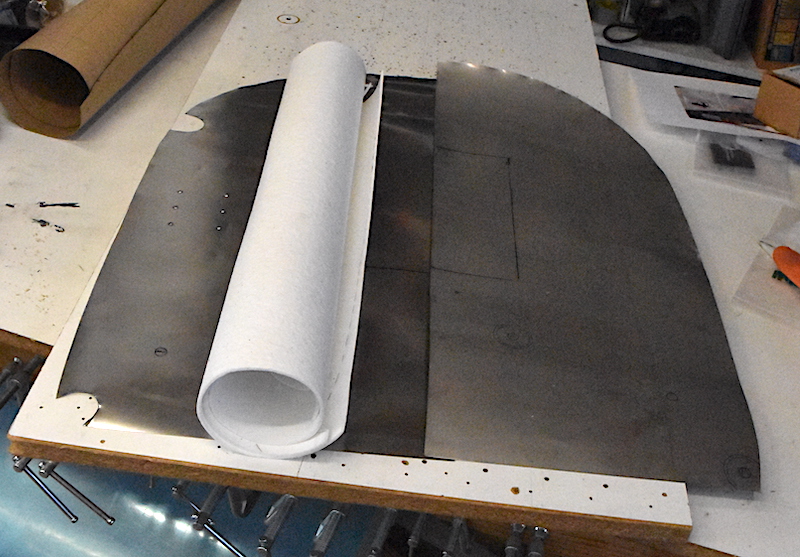

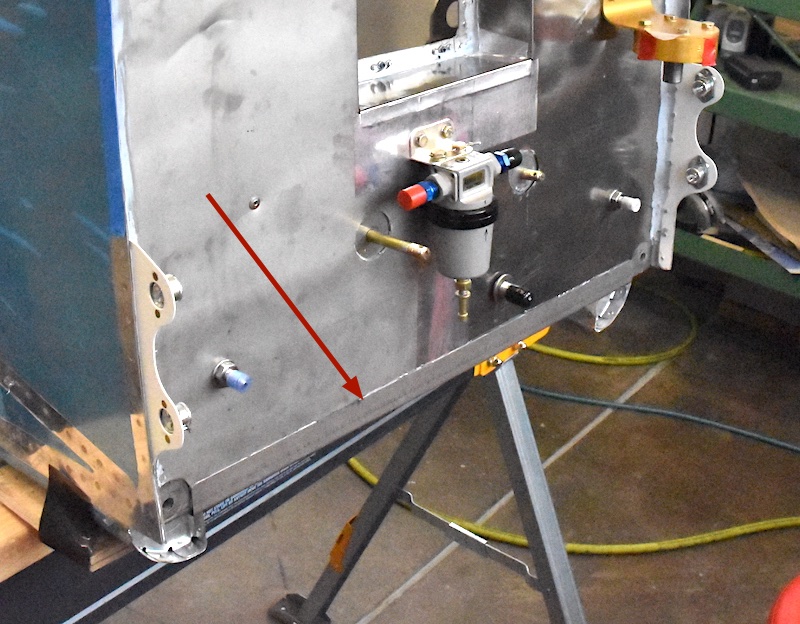

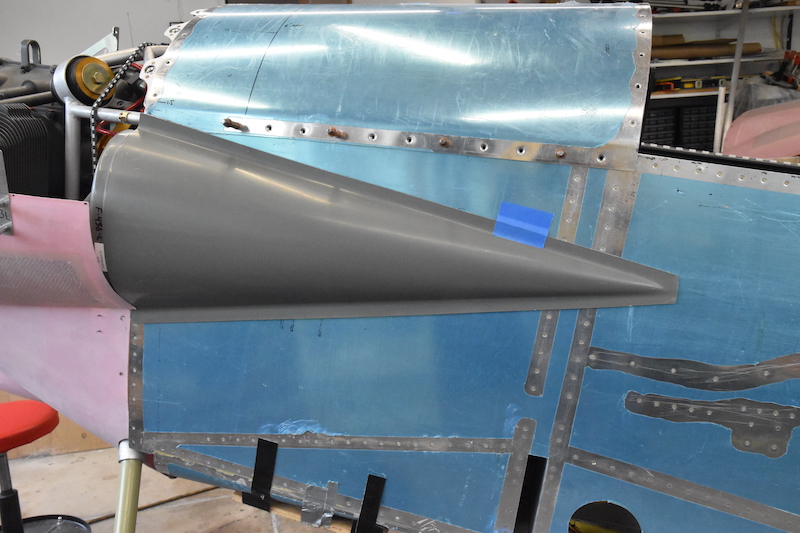

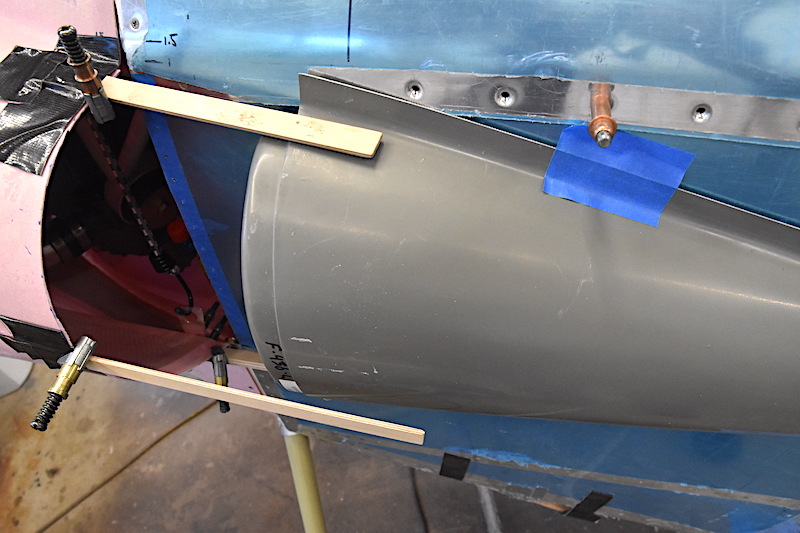

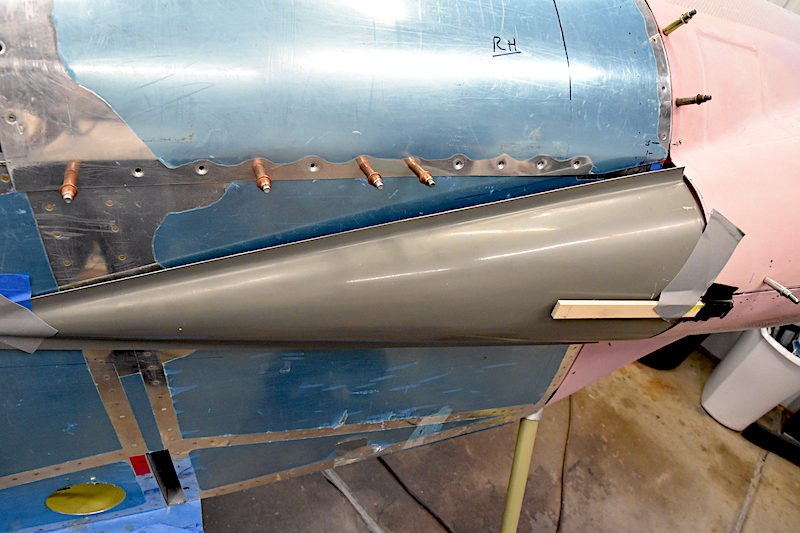

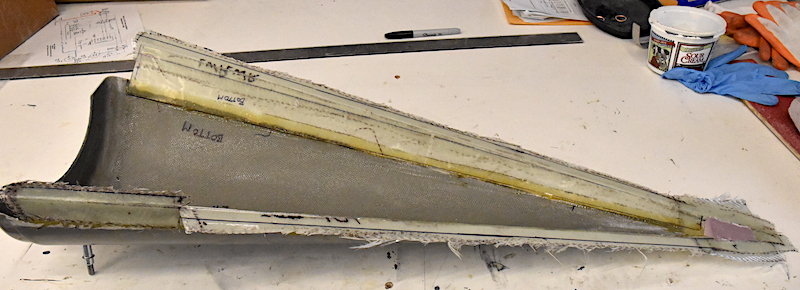

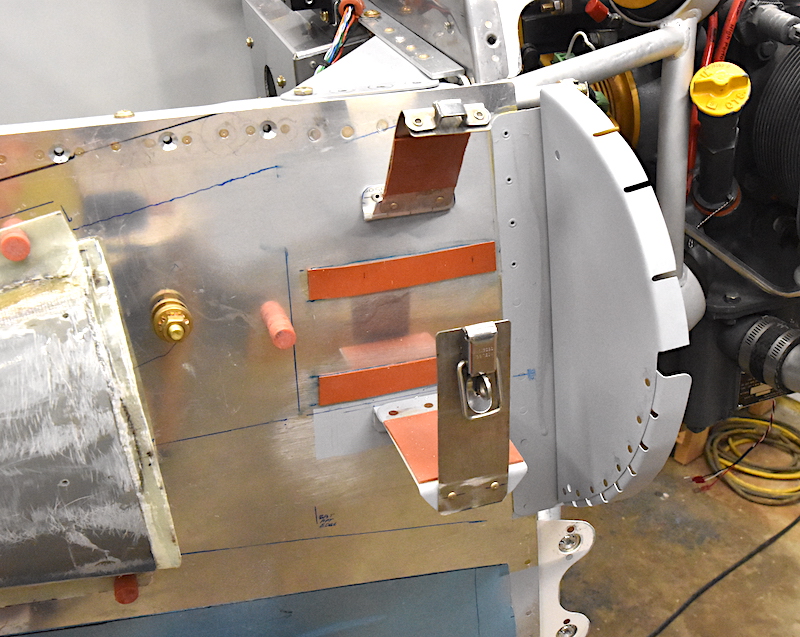

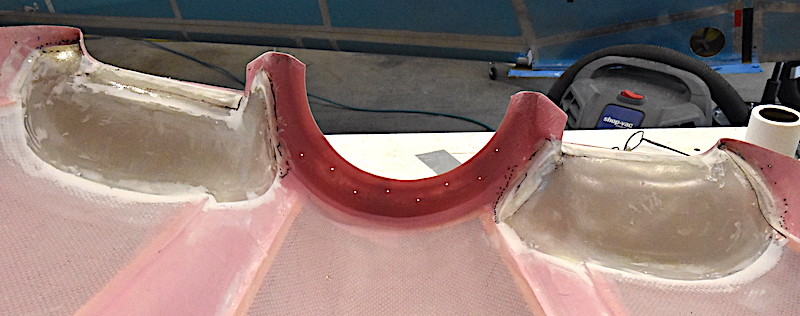

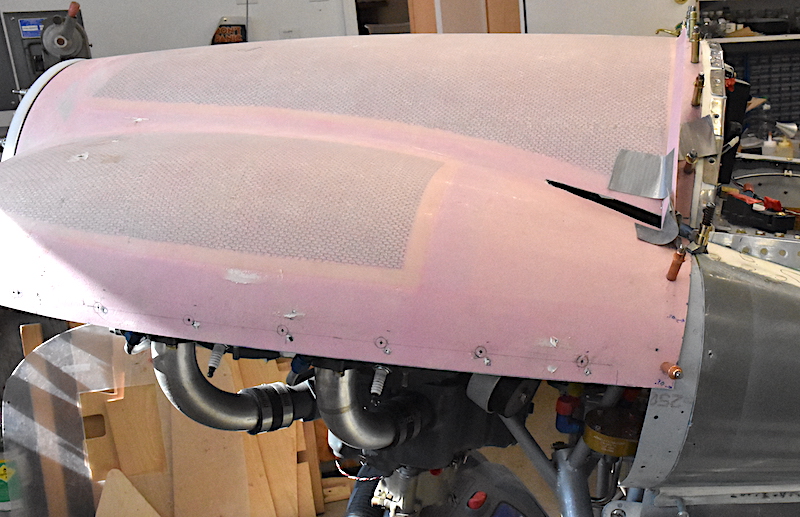

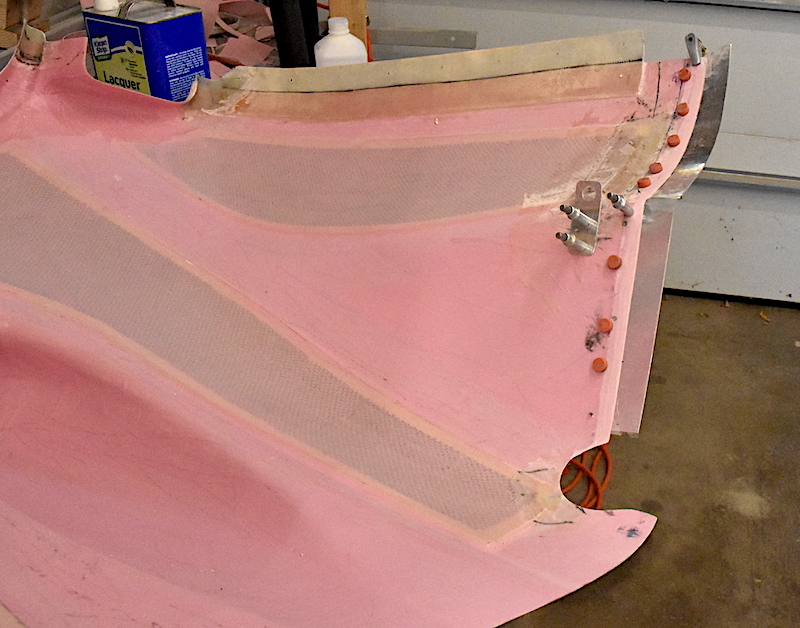

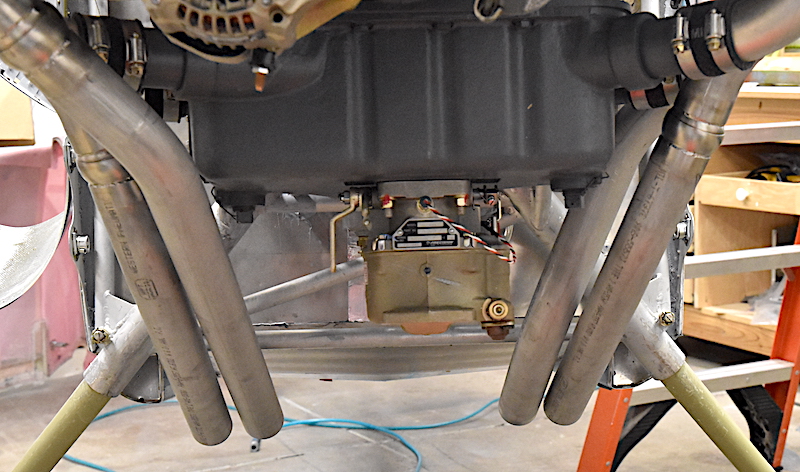

Since I hadn’t known when things could happen, I had a bit of spare time between the plating removal and the welding. I’d been working slowly on the engine baffles as fill-in projects. With the usual cursing, I was able to get the back baffle pieces in place. As you can see from the untrimmed top of the baffles, the ignition cable draped over the top, and the fact that the blue vinyl is still on and a couple other minor things, this is a work in progress.

I removed the baffles for the next step, in spite of being able to progress with this. It was time for something else.

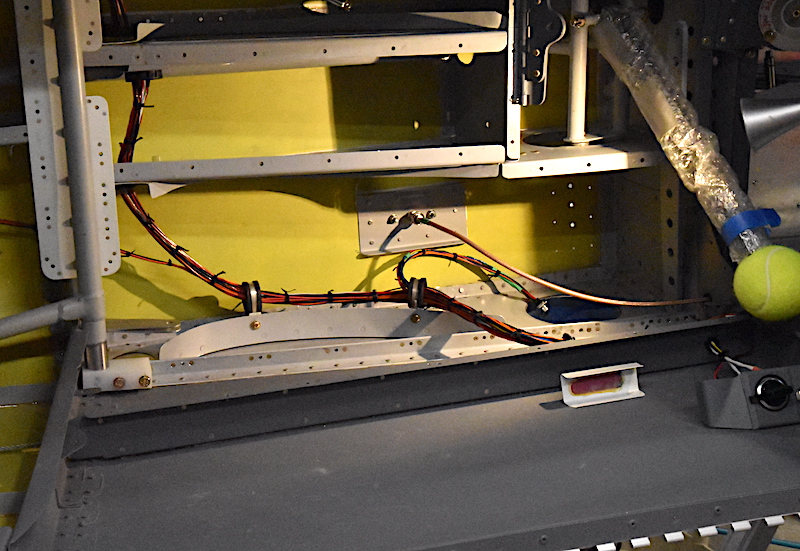

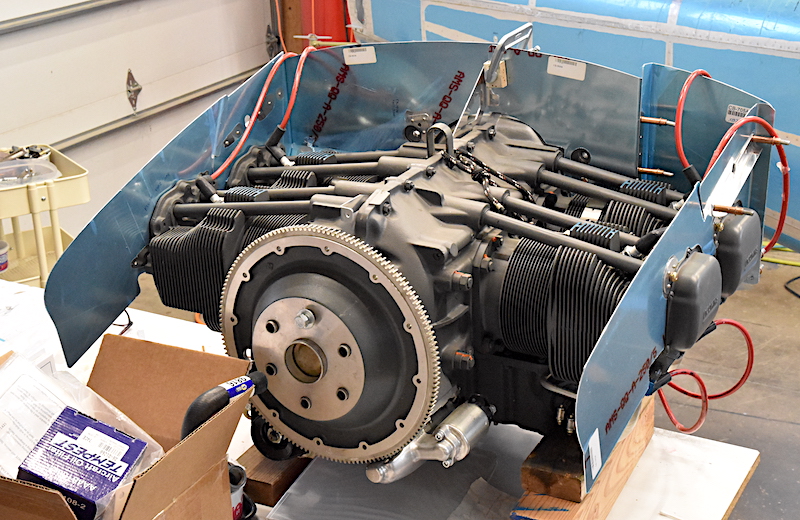

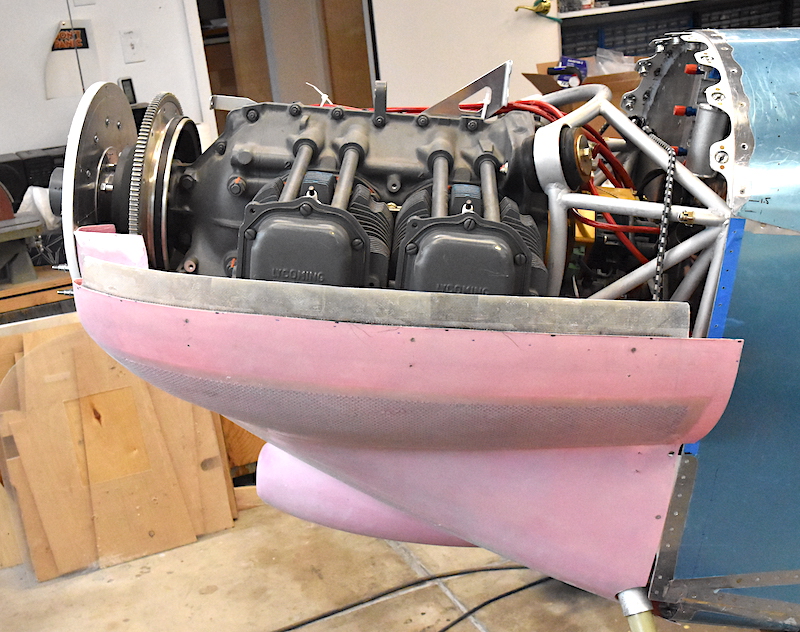

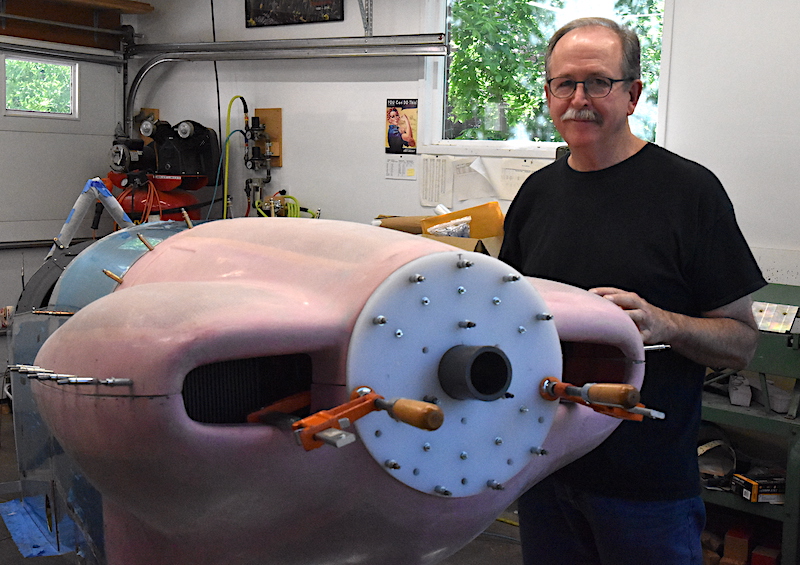

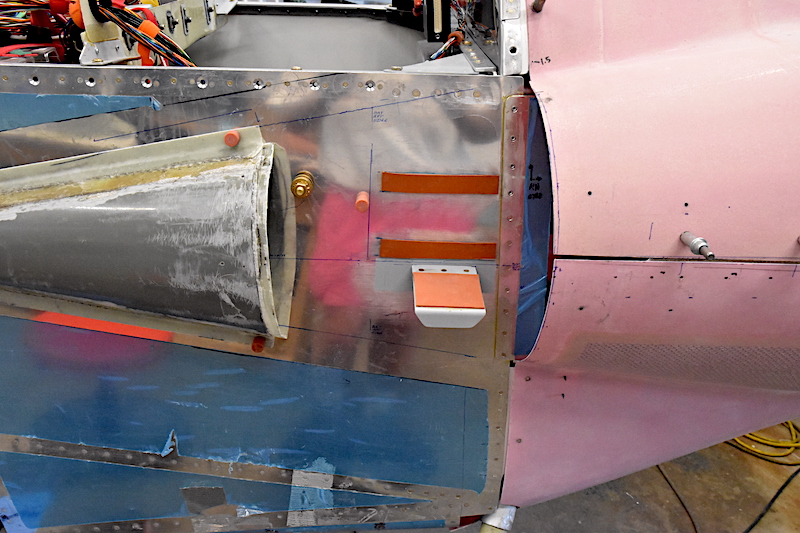

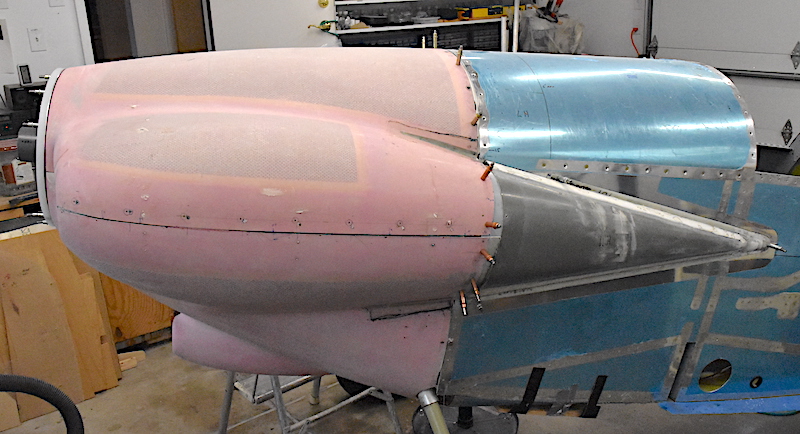

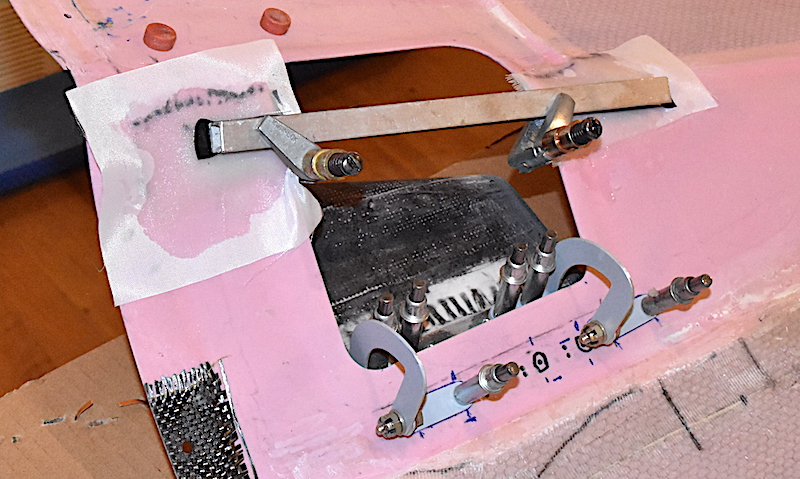

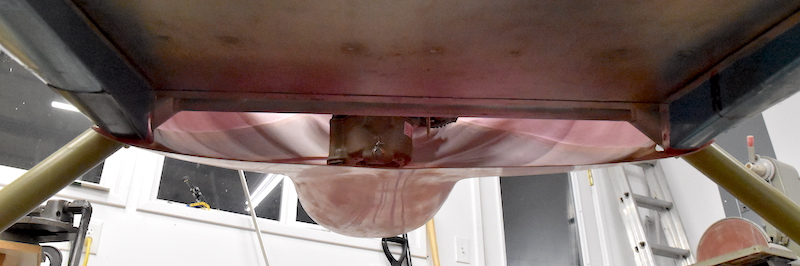

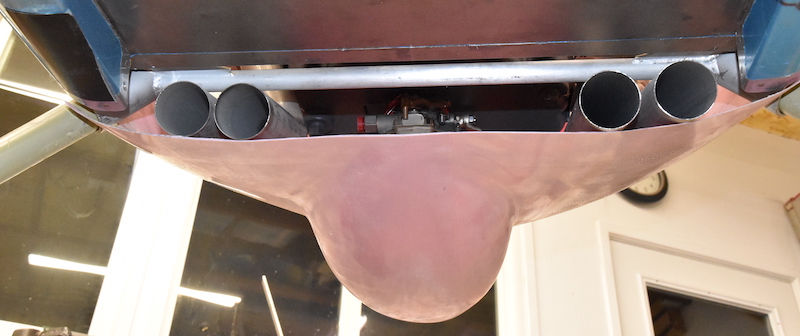

Remember that the engine was on my work table. I’d made a crucial error building the table back in ’12; I hadn’t allowed enough clearance under it for the engine hoist, or even a floor jack. Wirejock (AKA Larry Larson) came by to help and so did mtnflyr (AKA Rick Brennan) to help with the engine installation. Larry hoisted the table, I shoved the jack under it and lifted, Rick stabilized the engine, and we maneuvered the hoist in place and picked up the engine. I’d moved the fuselage partly outdoors to get more room in the shop for this, so we put the engine in place.

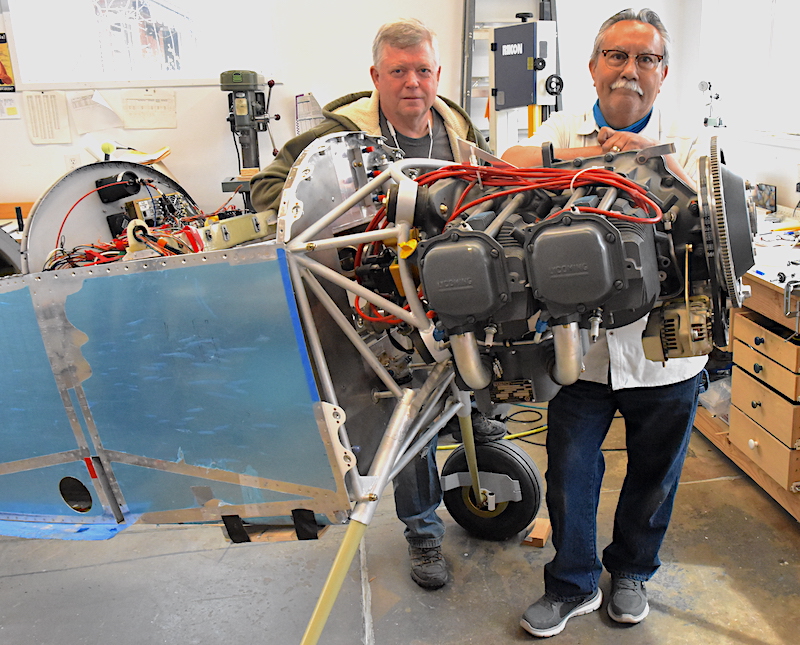

With rather a lot more work than I’d expected, Rick and Larry got all four isolators, bolts and nuts installed. I certainly could not have done it by myself. Fortunately both guys had not only done it for their planes, they both offered to help me. I did very little; they were the installers. And I’m mighty glad that they were both here.

Thanks, both of you!

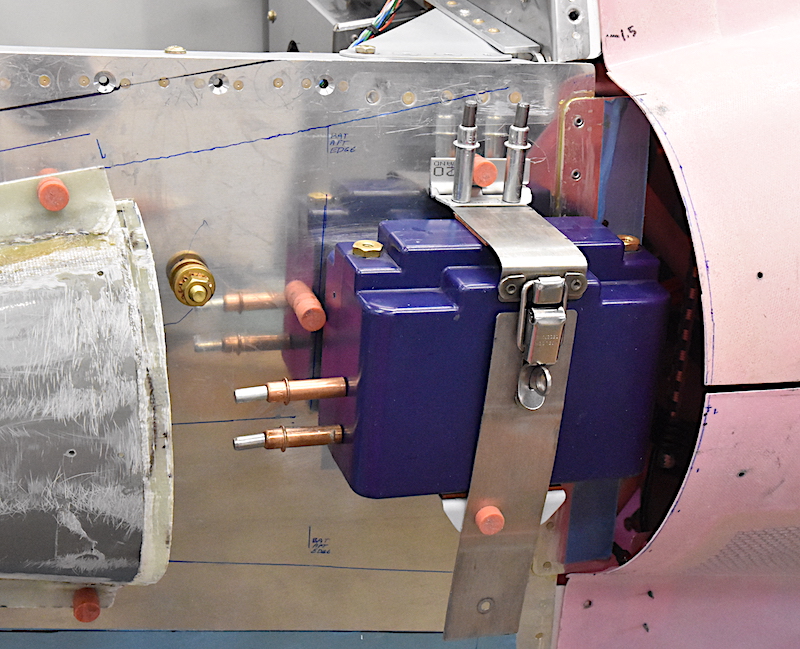

They look a bit concerned because at this moment it was not going smoothly.

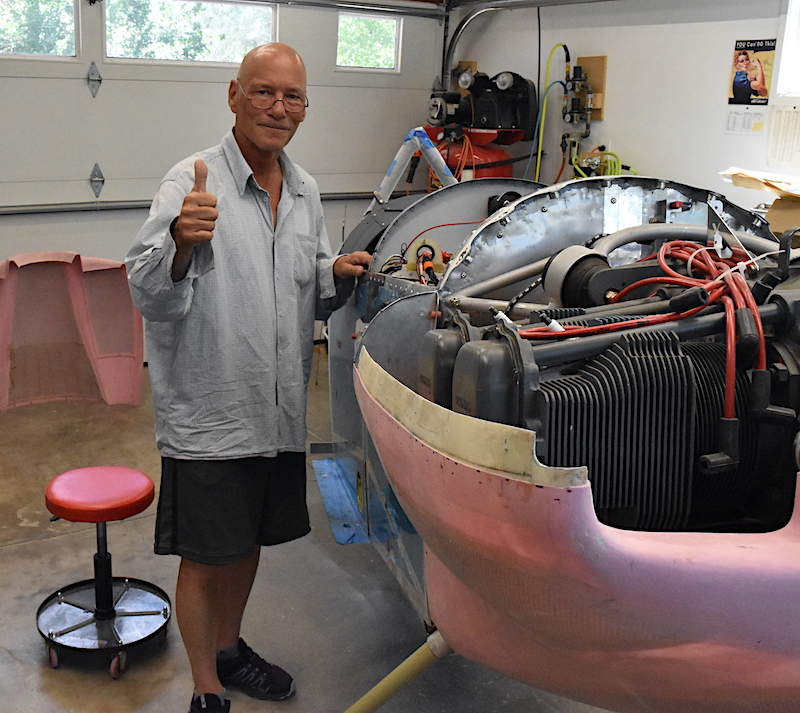

Once the job was done, they left, after posing for this job well done photo.

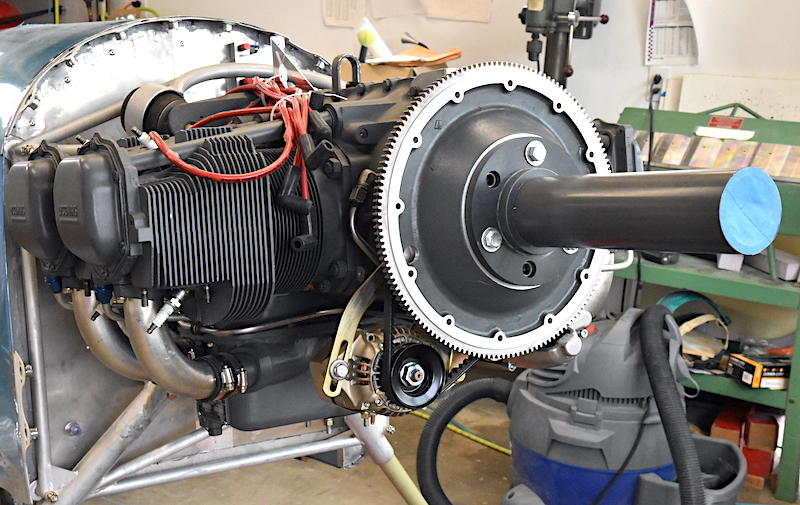

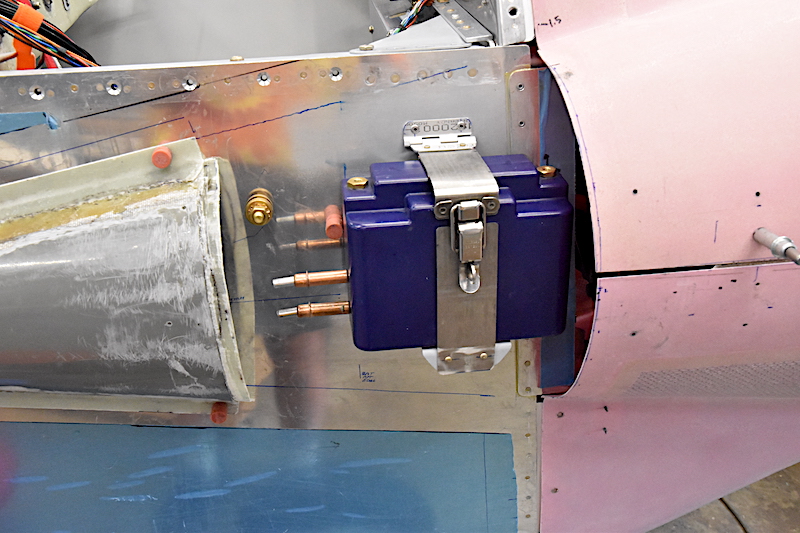

Afterwards, I torqued the nuts and took this close-of-day photo.

These guys saved my bacon more than once. Thanks again.

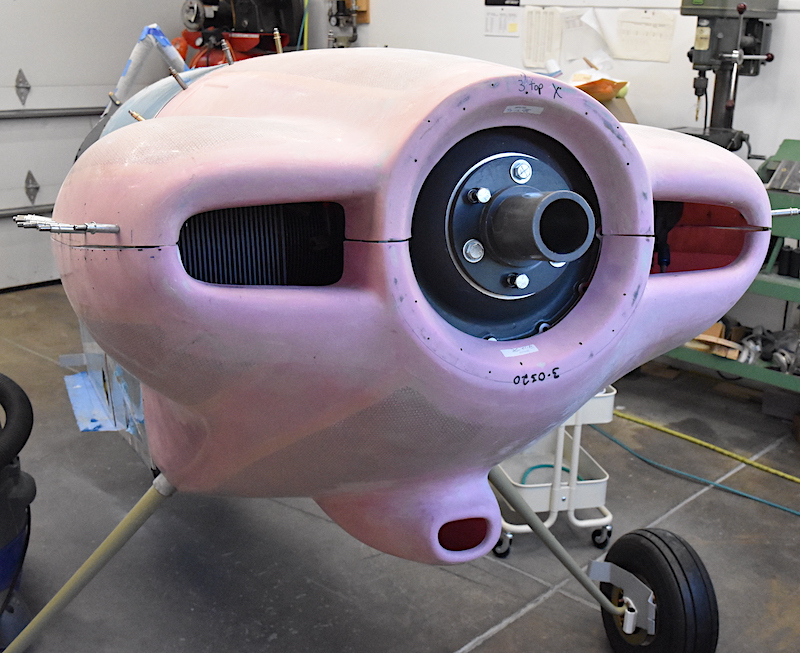

The engine’s on. Now there’s lots of things I can do.

Worth noting is that with the tailwheel on and about 30 pounds of weights on the aft deck, the plane is stable. When I raised the tail and it approached level, though, it was getting awfully light. Those weights are important.

Dave