I need to replace my (recently acquired) RV6's alternator which failed in-flight today after showing some output fluctuation on a recent flight. It currently has a Plane-Power 99-1012 alternator that lasted 437 Hobbs hours (38 months). My son and I have seen numerous reviews lately that indicate Plane-Power alternators are not as good as they used to be, so we're open to better quality options - BUT want to avoid any major hassles with fit/installation of an alternate brand.

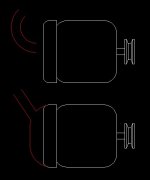

While we're open to all suggestions, we've read good things about B&C (and recently installed their starter). Visiting their website it looks like their LX60 (https://bandc.com/product/lx60-alternator-60-amps-homebuilt/#alternator) may be the appropriate model for our RV6. However, it indicates it does NOT have an internal voltage regulator (the Plane-Power does). Not sure how much of a hassle it would be to add the needed external voltage regulator.

Bottom line, I'm wondering if anyone here has experience replacing a Plane-Power 99-1012 alternator with another/better brand - and does anyone have experience with B&C alternators?

While we're open to all suggestions, we've read good things about B&C (and recently installed their starter). Visiting their website it looks like their LX60 (https://bandc.com/product/lx60-alternator-60-amps-homebuilt/#alternator) may be the appropriate model for our RV6. However, it indicates it does NOT have an internal voltage regulator (the Plane-Power does). Not sure how much of a hassle it would be to add the needed external voltage regulator.

Bottom line, I'm wondering if anyone here has experience replacing a Plane-Power 99-1012 alternator with another/better brand - and does anyone have experience with B&C alternators?