RFSchaller

Well Known Member

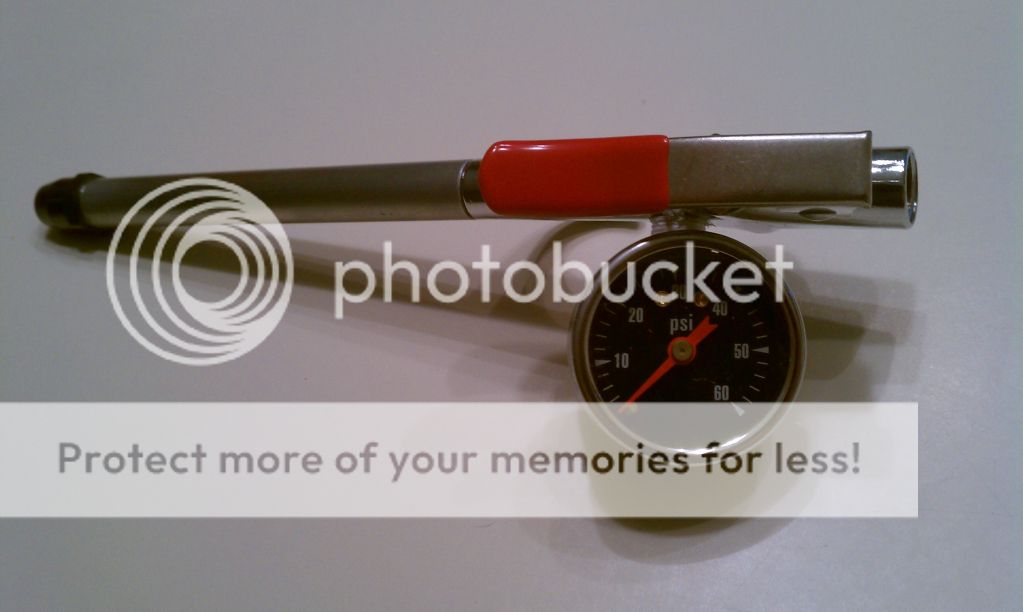

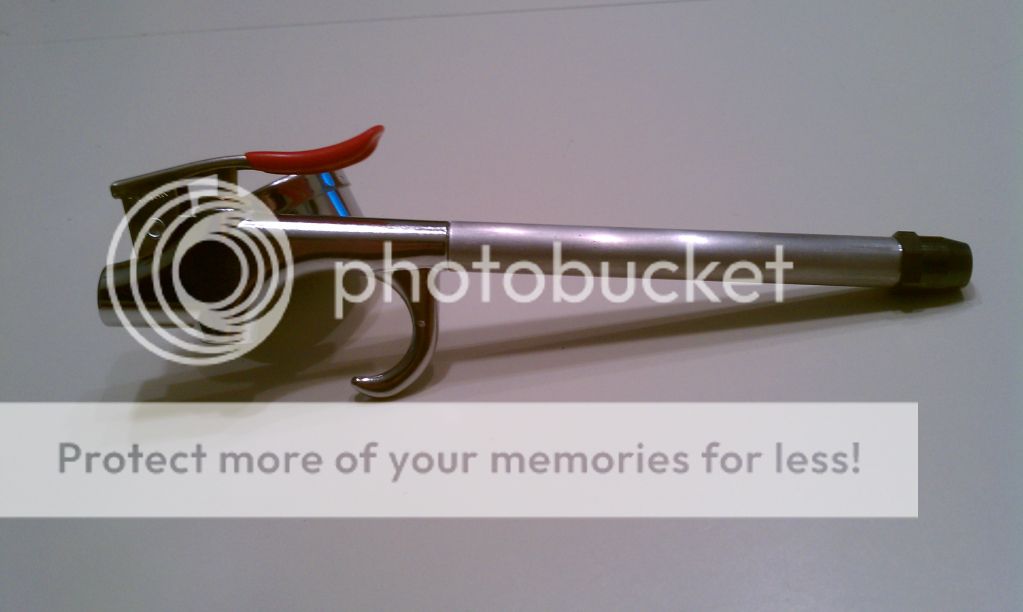

Those wheel pants look great, but today I had a low tire and had to add air. What a pain in the butt compared to my Cherokee. Has anybody come up with a convenient way to add air? I thought about a door or access cover, but it seems like I wouldn't be able to reach the cap the get it off the stem. How about extensions on the stems? Any ideas, guys?