jscottpilot

Active Member

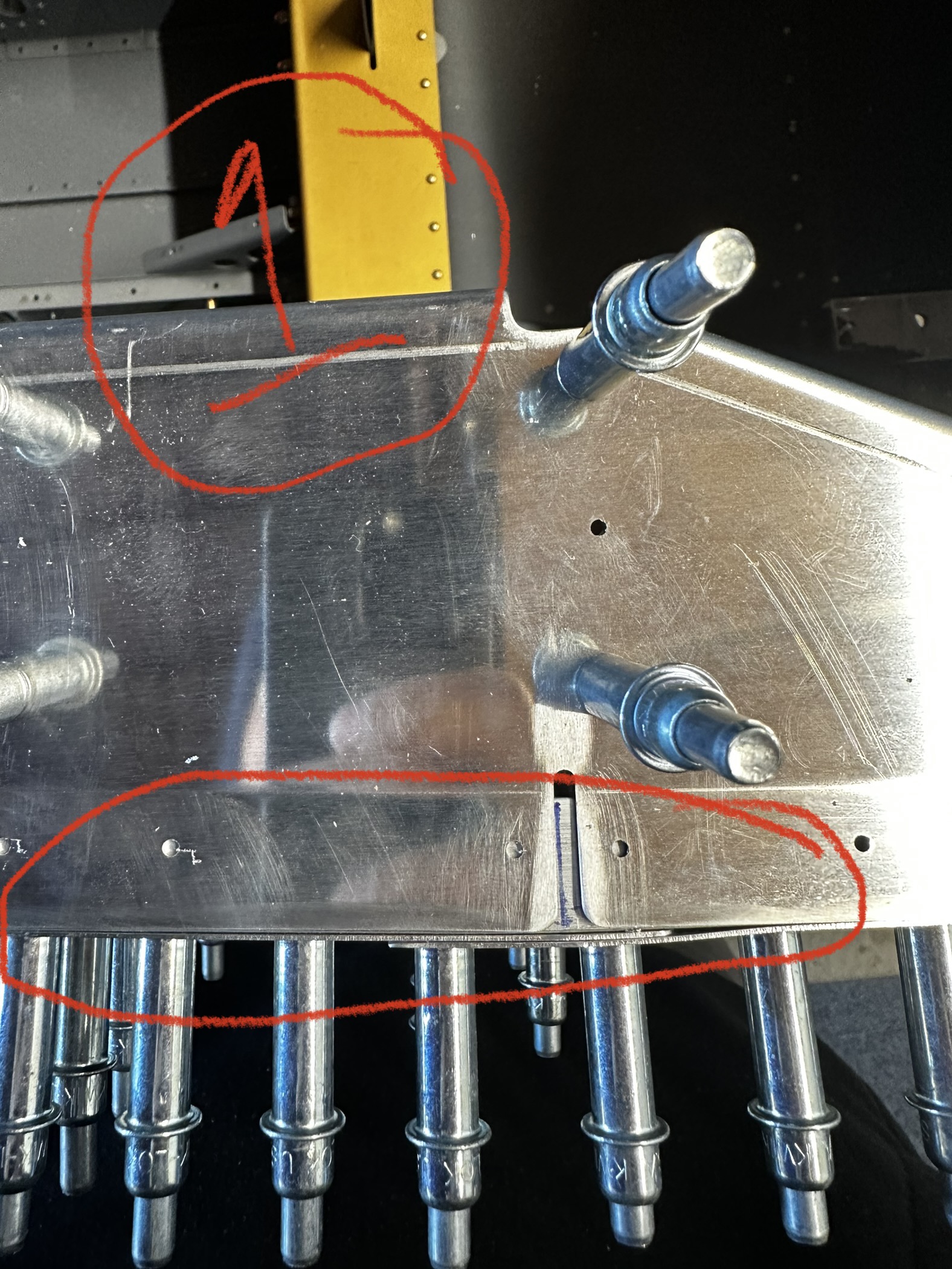

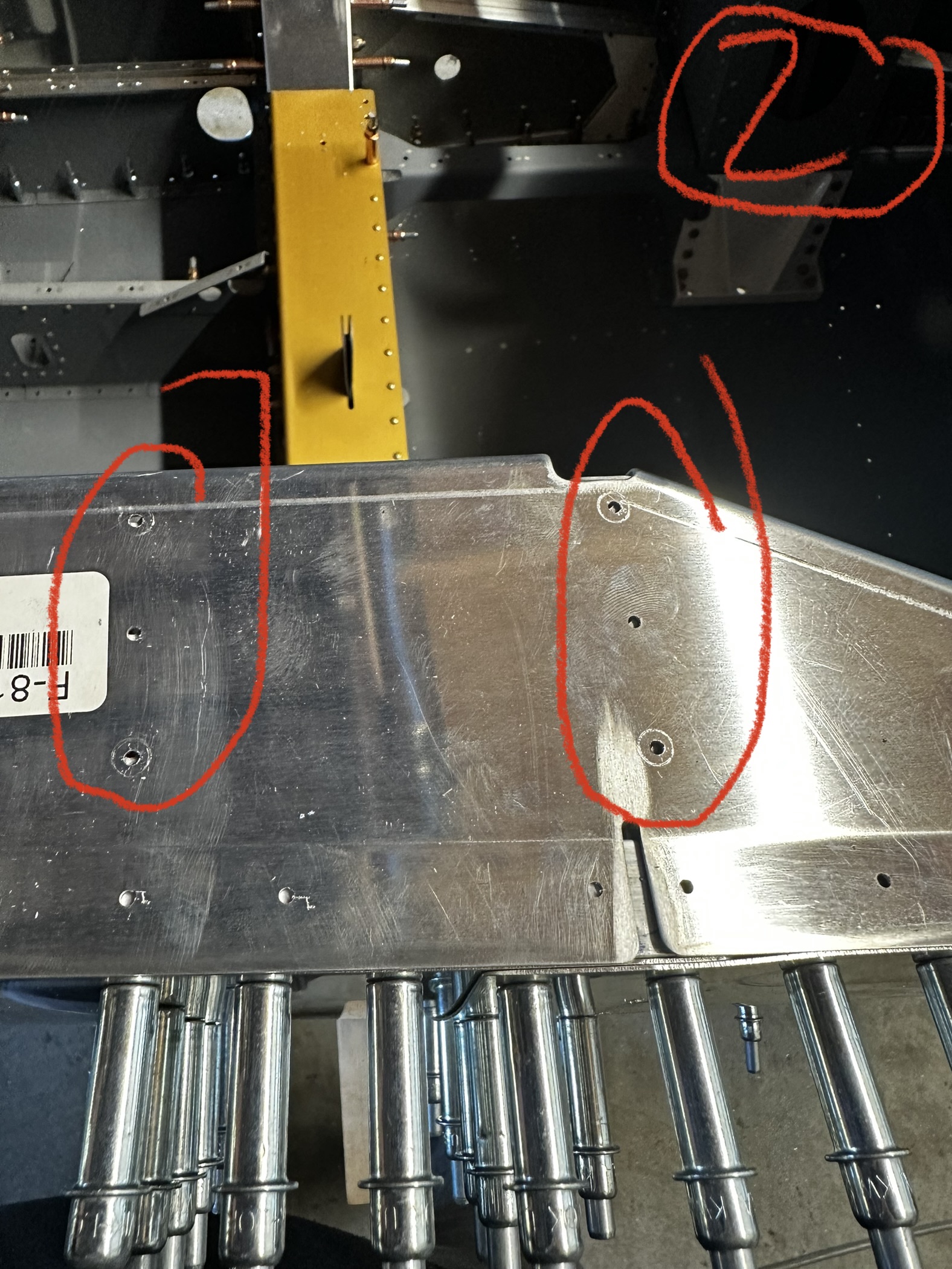

I have a new fuselage kit. All has gone together pretty easy to this point. I am on page 8-28 of the instructions where it says "Align the outboard edge of the 816 Cockpit rails so they are flush with the outer surface of the F-823-1 Mid Side Skins and clamp in position. Note: Pay particular attention to the fwd end of the cockpit rail."

I have done exactly what they have said to do. I can align the edge of the cockpit rails with the outer skin all the way up to the wing center section and I can align the forward part of the rail. Where I run into a problem is where the two skins meet up. I am about .070 inside of the outer skin. Frankly I dont see how you can align with the outer edge of the skin because the cockpit rail is straight and does not take into account the thickness of the outer skin.

If someone has experience with this I would appreciate some help.

I have done exactly what they have said to do. I can align the edge of the cockpit rails with the outer skin all the way up to the wing center section and I can align the forward part of the rail. Where I run into a problem is where the two skins meet up. I am about .070 inside of the outer skin. Frankly I dont see how you can align with the outer edge of the skin because the cockpit rail is straight and does not take into account the thickness of the outer skin.

If someone has experience with this I would appreciate some help.