Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips for heavy right wing

- Thread starter ten4teg

- Start date

https://www.vansaircraft.com/faq-technical-builder-items/how-to-diagnose-and-fix-a-heavy-wing/

Van's has a document to troubleshoot and fix.

Van's has a document to troubleshoot and fix.

scottmillhouse

Well Known Member

I have not found that very effective. On my 12 for a heavy right wing I altered the flapperon position slightly. The root attach point is fixed. Try a full turn in for the outer attach bearing fixture and 1/2 turn for the middle. Fly and note effect and adjust accordingly.Looking for some tips in correcting a heavy right wing. The ball is centered, but still a heavy right wing. I remember a tip from other RV models of crimping the trailing edge of the heavy wing aileron. Does this work on the RV12? Thanks

Worked well for 5 local 12s that I’m aware of.

I have not found that very effective. On my 12 for a heavy right wing I altered the flapperon position slightly. The root attach point is fixed. Try a full turn in for the outer attach bearing fixture and 1/2 turn for the middle. Fly and note effect and adjust accordingly.

Worked well for 5 local 12s that I’m aware of.

Don’t forget the Loctite…

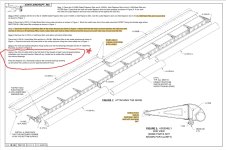

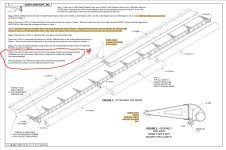

Attachments

ten4teg ...

Before getting draconian bending flaperon trailing edges, have a look at the two links below. I too had a heavy wing (left in my case) and following a tip from a fellow builder, I was able to resolve the issue by making sure the wing skin that cantilevers aft of the rear wing spar is flat with that portion forward of the rear spar. Some places were a little high and some were a little low on both wings.

Tweaking the wing skins up or down as necessary & checking every couple of inches solved my issue. All was good until I had the airplane painted and the heavy wing came back .... repeated the process and all was good again. Assuming all the pressure from sanding and paint prep tweaked the metal a little.

This may not fix your heavy wing ... but it is a good place to start and at least you'll know that this portion of the wing is right and not your issue.

http://www.dogaviation.com/2016/11/what-to-do-about-heavy-wing.html

http://www.dogaviation.com/2016/11/the-eagles-heavy-wing-issue-solved.html

Happy flying,

Before getting draconian bending flaperon trailing edges, have a look at the two links below. I too had a heavy wing (left in my case) and following a tip from a fellow builder, I was able to resolve the issue by making sure the wing skin that cantilevers aft of the rear wing spar is flat with that portion forward of the rear spar. Some places were a little high and some were a little low on both wings.

Tweaking the wing skins up or down as necessary & checking every couple of inches solved my issue. All was good until I had the airplane painted and the heavy wing came back .... repeated the process and all was good again. Assuming all the pressure from sanding and paint prep tweaked the metal a little.

This may not fix your heavy wing ... but it is a good place to start and at least you'll know that this portion of the wing is right and not your issue.

http://www.dogaviation.com/2016/11/what-to-do-about-heavy-wing.html

http://www.dogaviation.com/2016/11/the-eagles-heavy-wing-issue-solved.html

Happy flying,

Last edited:

Amadeus

Well Known Member

Looking for some tips in correcting a heavy right wing. The ball is centered, but still a heavy right wing. I remember a tip from other RV models of crimping the trailing edge of the heavy wing aileron. Does this work on the RV12? Thanks

Do not crimp. Take the advice of Jim Stricker (Piper J3). I did and it works!

Piper J3 Advice

I'd like to view and consider Jim's advice, but it looks like he sent it to you in a PM.

Do not crimp. Take the advice of Jim Stricker (Piper J3). I did and it works!

I'd like to view and consider Jim's advice, but it looks like he sent it to you in a PM.

Amadeus and PiperJ3, my aircraft is apart for mods and condition inspection for at least a couple of weeks probably more. If Jim's recommended procedure is better discussed than posted, I'll PM Jayson or Jim when the time comes.I can get involved, but might be best that Jayson (Amadeus) play-it-forward to DaveWelch. Either way... PM if you don't get info and I'll give you phone number to call me and I'll talk you through it like I did Jayson.

Best Wishes for the Holidays everyone,

Dave

Piper J3

Well Known Member

This has been discussed a few different times in this forum, most recently here…. https://vansairforce.net/community/showthread.php?t=211516

This is my post #2 from above thread: I purchased my RV-12 from the original builder with 48TT and it had a heavy right wing. I tried squeezing trailing edge of Flaperon and couldn’t discern any improvement. I lengthened / shortened the mid and outboard bearing rod-ends and achieved near perfect lateral balance. Airplane flies with ball centered in cruise flight. Airplane remains in lateral balance with full flap extension. Worked a charm….

I did not keep notes of the actual adjustments, but ended up lengthening on one wing and shortening on the other to minimize the deviation from spec. Wings were not pulled out of the fuselage to make adjustments. Simply remove the hinge pivot bolts and then twist the rod-ends. Have someone support the end of the Flaperon at the wing tip when making adjustment. If I remember correctly, none of the rod-ends were moved more than 1-1/2 turns. It took a few iterations and test flights to resolve the wing-heaviness. This work was done early-on and airplane now has > 800TT.

This is my post #2 from above thread: I purchased my RV-12 from the original builder with 48TT and it had a heavy right wing. I tried squeezing trailing edge of Flaperon and couldn’t discern any improvement. I lengthened / shortened the mid and outboard bearing rod-ends and achieved near perfect lateral balance. Airplane flies with ball centered in cruise flight. Airplane remains in lateral balance with full flap extension. Worked a charm….

I did not keep notes of the actual adjustments, but ended up lengthening on one wing and shortening on the other to minimize the deviation from spec. Wings were not pulled out of the fuselage to make adjustments. Simply remove the hinge pivot bolts and then twist the rod-ends. Have someone support the end of the Flaperon at the wing tip when making adjustment. If I remember correctly, none of the rod-ends were moved more than 1-1/2 turns. It took a few iterations and test flights to resolve the wing-heaviness. This work was done early-on and airplane now has > 800TT.

Amadeus

Well Known Member

I can get involved, but might be best that Jayson (Amadeus) play-it-forward to DaveWelch. Either way... PM if you don't get info and I'll give you phone number to call me and I'll talk you through it like I did Jayson.

Absolutely happy to help! PM me for my phone number and call when you are at your wing.

Jayson

Last edited:

Amadeus

Well Known Member

I did not keep notes of the actual adjustments, but ended up lengthening on one wing and shortening on the other to minimize the deviation from spec. Wings were not pulled out of the fuselage to make adjustments. Simply remove the hinge pivot bolts and then twist the rod-ends. Have someone support the end of the Flaperon at the wing tip when making adjustment. If I remember correctly, none of the rod-ends were moved more than 1-1/2 turns. It took a few iterations and test flights to resolve the wing-heaviness. This work was done early-on and airplane now has > 800TT.

Keep in mind that the flaperon does not need to be (and should not be) pulled away from the fuselage. Have someone (can be almost anyone, their role is very simple) helping as you will need a hand holding the outbound end of the flaperon as you make adjustments.

The flaperon has two hinge points; one about mid-wing and the other at the outer end. Remove the nut from both of these. Have your helper hold the outer end of the flaperon as you remove the pin/bolt from each of the hinge points. Once both are removed have your helper lift the flaperon upward just enough to clear the spherical portion of the hinge. Do not use a screwdriver or rod through the center of the spherical rod. I used an open end wrench slipped over the narrow of the sphere.

If you have a heavy right wing then begin with the left wing. It took three adjustments to get mine correct. The first adjustment was loosening the mid-wing spherical rod a half turn and the outer end one full loosening turn. After reattaching the flaperon - going from memory I'm thinking it was an AN3 and used the appropriate torque - I took off, stayed in the pattern and let go of the stick on the downwind to find my right wing a little less heavy than before.

Taxied back to the hangar and repeated the process taking the mid-wing hinge another full turn - making it a total of one and a half loosening turns. The outer hinge was then taken another full turn making it a total of two full loosening turns. Reattached, torqued and took off again only to find on the downwind that I now had a slightly heavy LEFT wing now.

Taxied back to hangar and repeated the process again. I noticed that the top of the flaperon was uncomfortably close to the top wing skin so when I made adjustments this time I tightened the mid-wing hinge one full turn and tightened the outer hing a half turn. Reattached, torqued and took off again. This time I flew the entire downwind leg hands off with level wings!

My total adjustments were a half turn looser on the mid-wing hinge point and one-and-a-half turns looser on the outer hinge point. I never had to make an adjustment to the right wing. Just keep an eye on the clearance between the wing skin and the flaperon. This worked for Jim and it worked for me; hopefully it will work for you, as well!

Last edited:

Keep in mind that the flaperon does not need to be (and should not be) pulled away from the fuselage. …

…hopefully it will work for you, as well!

Has anyone been told this is ok, by Vans?

Doing this breaks the bond the Loctite created during assembly. There are no jam nuts on the flaperon rod ends, so now they are loose, and free to vibrate and wear the threads. I sure would like to hear from Vans on this, and the implications of not resecuring the rod ends.

Attachments

Piper J3

Well Known Member

When I bought my 12 from original builder, it had a homemade trim tab fastened to the lower left outboard flaperon. The sheet metal tab was attached with double-sided foam tape (3M Body Molding Tape) and it functioned OK. Looked bad... but functioned OK. I removed the tab and adjusted the flaperon hinge lengths. Ball centered in cruise and wings level in all flight regimes. Works a charm….

Amadeus

Well Known Member

Has anyone been told this is ok, by Vans?

Doing this breaks the bond the Loctite created during assembly. There are no jam nuts on the flaperon rod ends, so now they are loose, and free to vibrate and wear the threads. I sure would like to hear from Vans on this, and the implications of not resecuring the rod ends.

The spheres at the end of the rod that create the hinge point have a bolt and nut through them to hold the flaperon in place. They are not going to spin with or without loctite. I still keep an eye on these when I preflight and have not seen or felt any movement (nor do I expect to).

These are VERY tight. Even on my final adjustment that turned the rod back inward it was very tight and not anything remotely close to free spinning.

As always, these are experimental airplanes and all owner/pilots should consider and weigh the risks and rewards. To me it is much more safe to have a an aircraft that flies level than making a sharp bank to the right when hands off and am very pleased with making this adjustment.

A qualified answer from Van's would be nice, but my *speculation* here is that the loctite is there to prevent galling via lubricity within the threads. It seems like that would be preserved even after making the adjustment. They can not vibrate and turn loose, but could potentially vibrate and cycle enough to damage the threads. Loctite is still present in the threads.

I may not be putting together the right words, but what I mean is that I also think the 'old loctite' is still doing it's job after an adjustment.

I may not be putting together the right words, but what I mean is that I also think the 'old loctite' is still doing it's job after an adjustment.

The spheres at the end of the rod that create the hinge point have a bolt and nut through them to hold the flaperon in place. They are not going to spin with or without loctite. I still keep an eye on these when I preflight and have not seen or felt any movement (nor do I expect to).

These are VERY tight. Even on my final adjustment that turned the rod back inward it was very tight and not anything remotely close to free spinning.

As always, these are experimental airplanes and all owner/pilots should consider and weigh the risks and rewards. To me it is much more safe to have a an aircraft that flies level than making a sharp bank to the right when hands off and am very pleased with making this adjustment.

Lock it

Here’s a good explanation of the problem with unsecured rod end threads.

He explains it at the beginning of the video. Loctite 243 is used as a substitute for a jam nut. Loctite 243 is a thread LOCKER, not a lubricant. As he points out, rotation is not the big issue, vibration is. (Positively lock it!)

https://youtu.be/foyZLBneV08

https://www.henkel-adhesives.com/us/en/product/threadlockers/loctite_243.html

Adjustment of the flaperons this way might work great, but why not complete the “adjustment” by simply adding the additional step specified by the aircraft kit manufacturer in the assembly instructions?!? It’s obviously important, or Vans wouldn’t have specified it. “Easy” isn’t always optimal, or safe.

Here’s a good explanation of the problem with unsecured rod end threads.

He explains it at the beginning of the video. Loctite 243 is used as a substitute for a jam nut. Loctite 243 is a thread LOCKER, not a lubricant. As he points out, rotation is not the big issue, vibration is. (Positively lock it!)

https://youtu.be/foyZLBneV08

https://www.henkel-adhesives.com/us/en/product/threadlockers/loctite_243.html

Adjustment of the flaperons this way might work great, but why not complete the “adjustment” by simply adding the additional step specified by the aircraft kit manufacturer in the assembly instructions?!? It’s obviously important, or Vans wouldn’t have specified it. “Easy” isn’t always optimal, or safe.

Last edited:

The Loctite products have a lot of properties, even for 243 it includes lubrication, sealing, etc. TBH, thinking of it replacing a jam nut for the function in that video seems a little sketchy to me. In any case, I'm a 'follow directions guy'.

To that point, making the adjustment and being strict to the manual seems like it could get tricky. To really do it the way Van's says you would need to remove the wing and turn it over, then remove the bearing and apply the thread lock and give it 24hrs upside down before re-installing. It would take some very careful measuring and thread counting. You couldn't make the quick adjustments throughout a flying day that people describe here then stick with the combo that worked. If it took a few tries you could get some problematic build up of thread lock unless you also were cleaning the threads each time.

Instead of 243, a better choice might be 290. 290 is a medium strength wicking grade, intended for parts that are already assembled. To do this 'by the book' I suppose you would make adjustments and test fly, then pull the wing and flip it over to apply to the assembled bearing and give it the 24hrs to wick and set.

I'm getting close to finishing up my build, and I think this process will 290 will be my approach if/when I have a heavy wing.

To that point, making the adjustment and being strict to the manual seems like it could get tricky. To really do it the way Van's says you would need to remove the wing and turn it over, then remove the bearing and apply the thread lock and give it 24hrs upside down before re-installing. It would take some very careful measuring and thread counting. You couldn't make the quick adjustments throughout a flying day that people describe here then stick with the combo that worked. If it took a few tries you could get some problematic build up of thread lock unless you also were cleaning the threads each time.

Instead of 243, a better choice might be 290. 290 is a medium strength wicking grade, intended for parts that are already assembled. To do this 'by the book' I suppose you would make adjustments and test fly, then pull the wing and flip it over to apply to the assembled bearing and give it the 24hrs to wick and set.

I'm getting close to finishing up my build, and I think this process will 290 will be my approach if/when I have a heavy wing.

Here’s a good explanation of the problem with unsecured rod end threads.

He explains it at the beginning of the video. Loctite 243 is used as a substitute for a jam nut. Loctite 243 is a thread LOCKER, not a lubricant. As he points out, rotation is not the big issue, vibration is. (Positively lock it!)

https://youtu.be/foyZLBneV08

https://www.henkel-adhesives.com/us/en/product/threadlockers/loctite_243.html

Adjustment of the flaperons this way might work great, but why not complete the “adjustment” by simply adding the additional step specified by the aircraft kit manufacturer in the assembly instructions?!? It’s obviously important, or Vans wouldn’t have specified it. “Easy” isn’t always optimal, or safe.

Piper J3

Well Known Member

I don’t think we’re talking F-18 making arrested landings on a pitching flight deck at sea... Instead, E-SLA with AN rolled-thread spherical rod end that is almost full-length thread engagement. I would be more concerned about spherical ball / socket wear which is an easy visual inspection…

Folks, it's not complicated.

If you find it necessary to adjust the rod ends in or out to eliminate a heavy wing, after the rod ends have been adjusted and the RV-12's heavy wing is fixed .... Remove the rod ends while counting the number of turns it takes, reapply the Loctite, screw the rod ends back in place, wait 24 hours or more and happy flying.

If you find it necessary to adjust the rod ends in or out to eliminate a heavy wing, after the rod ends have been adjusted and the RV-12's heavy wing is fixed .... Remove the rod ends while counting the number of turns it takes, reapply the Loctite, screw the rod ends back in place, wait 24 hours or more and happy flying.