Back to the grind! Hope you had a nice weekend.

vr,dr

dr

vansairforce.net

vansairforce.net

md9680

www.vansairforce.net

www.vansairforce.net

mfleming

vansairforce.net

vansairforce.net

jimzap

vansairforce.net

vansairforce.net

Panel: Dougnabbit

I just wanted to give a shout out to all the employees at Advanced Flight Systems but especially Jenn, Kyle, and Duane in helping make the panel I wanted!

The experience and customer service was outstanding. I can’t say enough good things about them. Great people, great service!

vansairforce.net

vansairforce.net

Daily Pic: Vlad

Once a year the ramp at my airport is busy with a charitable event.

vansairforce.net

vansairforce.net

G zero

https://vansairforce.net/threads/2planes-1-tee-hangar.201246/post-1790836

A few years after my first post …

AD-41H rivet installation

…HFS reply

I recently "tested" some AD41H rivets I got from Spruce just for this purpose. Don't know if they are from the same production run as those you had trouble with, but with my thrifty (read - cheap) HF pneumatic puller, operating at 90 psi, with a speed reduction mod to help slow down the "snapping" action associated with these types of tools, I had acceptable results. Also used an "insulator" tool with a .068 hole to help reduce the possible of "feathering" of the soft aluminum head during the pulling process.

I also did a couple of overlap shear tests, using Pop's stated spec for this rivet as 385 lb ultimate shear. Neither test produced results that confirmed those specifications. Two samples: 2 x .032 w/2 AD41H rivets on 1" c-c yielded 540 lb & 530 lb at failure. By Pop's specs, should have been, at least, 385 x 2 = 770 lb. Not even close. My testing device is not an ASTM certified unit, but is does a good job for relative comparisons. It uses a 3K lb load cell with a digital readout - load application rate is ~ .1"/min.

vansairforce.net

vansairforce.net

JDA_BTR

Battery Shelf PIREP

.040 or .063 sheet stock. Some people used angle with a panel riveted to the top

I had a sheet of 0.04 here. I also had a spare length of J channel from my -14A build. So I built up this shelf. Does not bow a bit laterally. It does bow a tiny bit longitudinally if I press hard right in the middle but the boxes I screw to it will take that out. Weighs less than the 3/4 angle.

I figure the lateral tabs of sheet laying on the longeron are enough support for way more than I’ll mount here even allowing for g forces.

Two screws per side seems enough too. Might do three as it’s 5” wide and an extra in the middle couldn’t hurt.

Looking for feedback before I drill the longeron.

vansairforce.net

vansairforce.net

OFF TOPIC:

Previous Issue:

www.vansairforce.net

www.vansairforce.net

Please consider donating yearly to help keep this American 1-person pirate ship afloat:

Older issues of the ‘VAF News’ can be found at:

www.vansairforce.net

www.vansairforce.net

THE VAF LIST (a list of RV-related lists)

vansairforce.net

vansairforce.net

vr,dr

dr

WDYDWYRTW? (9 / 7-8 / 2024)

...getting this weekend's thread started. Hope everyone is having a nice one! v/r,dr

md9680

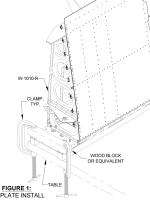

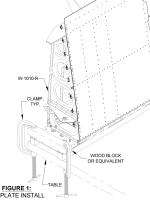

Page 16-03, 04, Step 2 Request

Will someone please post a picture of the installed row of K1000-08 plate nuts referenced in the drawing on page 16-03 and step 2 on page 16-04? I am particularly interested in how large the counter sinking is supposed to be for the screws. Thank you.

mfleming

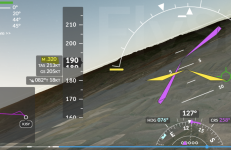

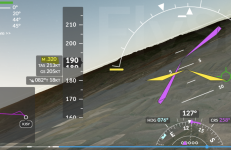

AutoPilot Scary Incident

I'm posting this because it surprised me on how easy and incipient it was. These RV are slippery...I know this and you know this but when it happens it can happen without warning. Here's a link to a flight I made this morning. Headed to the WAAAM Museum for their annual Fly-in. Level at...

jimzap

C-762 Canopy Slide Rail Bend

I'm trying to Bend the Canopy Rail so it conforms to the C-763 spacer. How did do I do this and make it conform nicely?

Panel: Dougnabbit

I just wanted to give a shout out to all the employees at Advanced Flight Systems but especially Jenn, Kyle, and Duane in helping make the panel I wanted!

The experience and customer service was outstanding. I can’t say enough good things about them. Great people, great service!

Show us your panel!

You only running 1 comm? Sorry, missed this back then. Yes, only one comm. After many years experience in my last plane with a -255 with monitor function as well, I am quite comfortable with a single comm and a handheld backup in the cockpit (and have decided radio navigation is not a...

Daily Pic: Vlad

Once a year the ramp at my airport is busy with a charitable event.

Daily RV Pic

RV-8 enjoying the morning around my house. I’m at the desk looking out and he or she has made a few passes. A nice morning here.

G zero

https://vansairforce.net/threads/2planes-1-tee-hangar.201246/post-1790836

A few years after my first post …

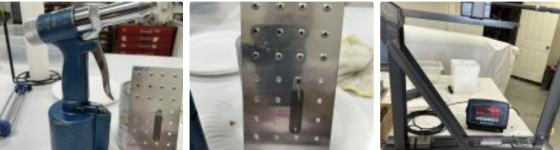

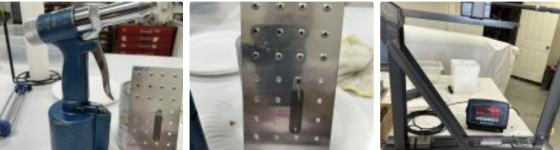

AD-41H rivet installation

…HFS reply

I recently "tested" some AD41H rivets I got from Spruce just for this purpose. Don't know if they are from the same production run as those you had trouble with, but with my thrifty (read - cheap) HF pneumatic puller, operating at 90 psi, with a speed reduction mod to help slow down the "snapping" action associated with these types of tools, I had acceptable results. Also used an "insulator" tool with a .068 hole to help reduce the possible of "feathering" of the soft aluminum head during the pulling process.

I also did a couple of overlap shear tests, using Pop's stated spec for this rivet as 385 lb ultimate shear. Neither test produced results that confirmed those specifications. Two samples: 2 x .032 w/2 AD41H rivets on 1" c-c yielded 540 lb & 530 lb at failure. By Pop's specs, should have been, at least, 385 x 2 = 770 lb. Not even close. My testing device is not an ASTM certified unit, but is does a good job for relative comparisons. It uses a 3K lb load cell with a digital readout - load application rate is ~ .1"/min.

AD-41H rivet installation

Is there a best method to use when pulling this type rivet that will produce a respectable outcome? I have about 1 out of 5 that resemble a decent finished rivet. The rest end up looking bad and they also plug up the rivetgun nosepiece to where you have to unscrew it and pound out the rivet...

JDA_BTR

Battery Shelf PIREP

.040 or .063 sheet stock. Some people used angle with a panel riveted to the top

I had a sheet of 0.04 here. I also had a spare length of J channel from my -14A build. So I built up this shelf. Does not bow a bit laterally. It does bow a tiny bit longitudinally if I press hard right in the middle but the boxes I screw to it will take that out. Weighs less than the 3/4 angle.

I figure the lateral tabs of sheet laying on the longeron are enough support for way more than I’ll mount here even allowing for g forces.

Two screws per side seems enough too. Might do three as it’s 5” wide and an extra in the middle couldn’t hurt.

Looking for feedback before I drill the longeron.

Aft battery shelf

Fabbed this up today. Still have to add sheet for rigidity. I’m thinking I’ll put a 10 space fuse panel and a gad27 back there. Perhaps a remote radio and maybe a remote audio panel depending on what my panel ends up at.

OFF TOPIC:

Previous Issue:

The VAF News - 9.5.2024. #6163. Wiring, Last Rivet, Blood, A/P, Leak, Bucking Bars, Tire Cut, Rock/Paper/Scissors

Little Wing (Wiring runs, and main spar reply.) Aft mounted dual batteries here grounded locally. Power wires ran through mid longerons. Everything else thought the floor. All my spar pass throughs are full. Pitot & static under and across floor. Power wires can be seen on both sides at the...

Please consider donating yearly to help keep this American 1-person pirate ship afloat:

Older issues of the ‘VAF News’ can be found at:

Doug's Area ....The VAF News & my flying resume.

Pushed out every now and then.

THE VAF LIST (a list of RV-related lists)

THE VAF LIST (a list of RV-related lists)

The VAF List ...a list of RV-related lists. RV-related things you might want to browse over (a closed post that is sticky and maintained by dr). Link to this in 'Links' in the menu. v/r,dr Small biz that brings you this page: 360 Avionics www.360Avionics.com Aircraft Extras...