During certain maneuvers I have noticed a rattling/banging noise coming from the back. I had a Gopro camara pointing backward and found that the noise is coming from vibrating HS/tail. As the video of this wingover shows

the tail is shaking shortly at sek 1 and again longer at sek 7/8. The noise is loud enough to hear through headset/cabin noise and can be heard in the video. I have multiple times looked for what could be loose in the back not realizing it was the tail shaking.

It seams to be related to high AOA and/or some disturbed air flowing from the wing and gear and hitting the HS.. I know the maneuver in the video wasn’t flown very clean but nevertheless revealed the problem.

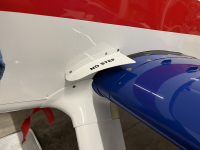

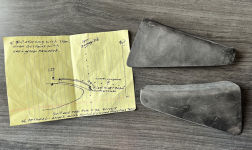

I think this tail shaking puts unnecessary stress on the tail and want to look for a solution. I contacted Vans support about this and they essentially pointed me to some threads here at vansairforce about strakes that some builders have installed over the leading edge of the wings to smooth the airflow at high AOA. Maybe I’m not following here enough but didn’t realize the connection between the noises and tail shake until now.

Reading through the links/info from Vans support I have a few questions which I think is better to adresse here:

There doesn’t seam to be a lot of feedback from people having installed these strakes. Do the they fix the problem?

My impression is that tailshake is mostly reported in a regular stall or 3 point landing. Have others also experienced in aerobatics or other situations?

Where to buy these strakes? Updated information on who sells these? The information I got doesn’t seam to be up to date.

Thanks for any help on this...

the tail is shaking shortly at sek 1 and again longer at sek 7/8. The noise is loud enough to hear through headset/cabin noise and can be heard in the video. I have multiple times looked for what could be loose in the back not realizing it was the tail shaking.

It seams to be related to high AOA and/or some disturbed air flowing from the wing and gear and hitting the HS.. I know the maneuver in the video wasn’t flown very clean but nevertheless revealed the problem.

I think this tail shaking puts unnecessary stress on the tail and want to look for a solution. I contacted Vans support about this and they essentially pointed me to some threads here at vansairforce about strakes that some builders have installed over the leading edge of the wings to smooth the airflow at high AOA. Maybe I’m not following here enough but didn’t realize the connection between the noises and tail shake until now.

Reading through the links/info from Vans support I have a few questions which I think is better to adresse here:

There doesn’t seam to be a lot of feedback from people having installed these strakes. Do the they fix the problem?

My impression is that tailshake is mostly reported in a regular stall or 3 point landing. Have others also experienced in aerobatics or other situations?

Where to buy these strakes? Updated information on who sells these? The information I got doesn’t seam to be up to date.

Thanks for any help on this...