Romeo-Victor

I'm New Here

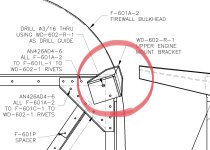

While doing my Annual Condition inspection I found what appears as a crack on each of the 4 support gussets for the engine mount supports at the firewall. It looks like the cracks are on a weld joint and I’m wondering if it’s something I can have rewelded and reinstalled or is it a piece I can get direct from Van’s. Has anyone ran into this? …and how did you take care of it??

This is on a RV6 s/n 24127

I already emailed Van’s and waiting on response from them.

Mike L.

This is on a RV6 s/n 24127

I already emailed Van’s and waiting on response from them.

Mike L.

Attachments

Last edited: