bryanhorgan

Member

I had my first ever rejected take off today.

While taxiing, I had what I thought was some light vapor lock.

Fuel pump on, increase RPMs, problem seemed to be solved.

Normal run-up. Go to take off. I'm full fuel, close to gross weight. Full power, adjusted mixture. Plane struggles a bit to take off (this is the point I SHOULD have rejected). I push on, thinking I'll gain speed and be fine.

Then I get a "ENGINE TEMPERATURE" warning. CHTs are 426. Not good.

I'm off the runway, in ground effect. I decide I have to land immediately.

Pull power to idle, fight ground effect, slam on brakes, stop 50ft short of the runway end.

I wanted to remind everyone to pay attention to your ground roll. If it seems slower, or longer than it should, REJECT the takeoff there.

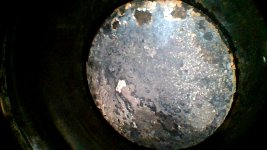

Also, anyone have any ideas on what would cause high CHTs so quickly? Fuel pressure was 6 psi (normal). I found an oil leak coming from between the engine case and the oil sump. Mid time Slick mags. 0-360 RV7A.

While taxiing, I had what I thought was some light vapor lock.

Fuel pump on, increase RPMs, problem seemed to be solved.

Normal run-up. Go to take off. I'm full fuel, close to gross weight. Full power, adjusted mixture. Plane struggles a bit to take off (this is the point I SHOULD have rejected). I push on, thinking I'll gain speed and be fine.

Then I get a "ENGINE TEMPERATURE" warning. CHTs are 426. Not good.

I'm off the runway, in ground effect. I decide I have to land immediately.

Pull power to idle, fight ground effect, slam on brakes, stop 50ft short of the runway end.

I wanted to remind everyone to pay attention to your ground roll. If it seems slower, or longer than it should, REJECT the takeoff there.

Also, anyone have any ideas on what would cause high CHTs so quickly? Fuel pressure was 6 psi (normal). I found an oil leak coming from between the engine case and the oil sump. Mid time Slick mags. 0-360 RV7A.