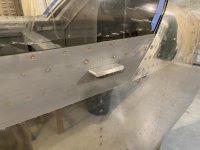

I’m finishing my slider skirts and such and think I need an aft handhold to assist opening.

I’ve seen rear handles on sliders mounted on the top bar to help lift the rear from the outside. I do not want to drill my canopy. What options have you all used to help lift the back of the slider? I’m thinking side hand hold mounted on the skirt? Not sure this will work well though. Seems like it will add a twisting load to the canopy. My slider operates ok but it is pretty tight when closed and needs some lifting action at the back.

I’ve seen rear handles on sliders mounted on the top bar to help lift the rear from the outside. I do not want to drill my canopy. What options have you all used to help lift the back of the slider? I’m thinking side hand hold mounted on the skirt? Not sure this will work well though. Seems like it will add a twisting load to the canopy. My slider operates ok but it is pretty tight when closed and needs some lifting action at the back.