I am on page 28-3 figure 3 of my RV-10 fuselage plans. There is a sentence 'machine countersink the nutplate screw holes. See Page 13-3, Figure 2 for details of the countersunk hole'. I have empennage plans and fuselage plans, but no plans for section 13. Can anyone help me with 'details of the countersunk hole as indicated on Page 28-3 three of my fuselage plans?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machine countersink nutplate screw holes

- Thread starter dspender

- Start date

Section 13 is a part of the wing kit plans. Here's a link to an image of the page put up by Tim Olsen. Just be aware that these plans were scanned some years ago and the current plans may have been updated.

http://www.myrv10.com/Plans/RV10_Plans_sec13-pg03.html

http://www.myrv10.com/Plans/RV10_Plans_sec13-pg03.html

This is very helpful Joe. It looks like it wants me to countersink just enough to accommodate an AD426AN3 rivet, although this is a nutplate. Evidently a portion of the skin or some other external structure at this site will be dimpled to keep the skin surface flush, but accommodate a screw instead of a rivet.

aturner

Well Known Member

Dennis, the overlying covers are secured with #8 screws, so you need to machine countersink the #19 screw holes in the bulkhead side channel to accept the dimples of the covers. Figure 2 of 13-3 basically says "don't countersink too deep", just deep enough to accept the dimpled sheet above it. You can make a test dimple in a piece of scrap and fit it to your countersunk holes to see if they are deep enough.

In my opinion, the plans here are in error here in that the middle screw hole of the five in the bulkhead side channel should not be countersunk. There are two layers above it, with the top one being the lower flange of the mid-cabin deck, which is itself countersunk for the #8 screw. No need to have another countersink buried under it. You can read ahead in the plans and decide for yourself.

Good Luck, -Andy

In my opinion, the plans here are in error here in that the middle screw hole of the five in the bulkhead side channel should not be countersunk. There are two layers above it, with the top one being the lower flange of the mid-cabin deck, which is itself countersunk for the #8 screw. No need to have another countersink buried under it. You can read ahead in the plans and decide for yourself.

Good Luck, -Andy

Last edited:

I don't have those wings plans (Page 13-). I countersunk enough to accommodate a number 3 rivet, as the page of those plans I received indicated. I have riveted into place the nutplate. However it appears to me that if I need to countersink further than I did, I will be able to do that even with the nutplate in place. Time will tell.

longranger

Well Known Member

For attaching nutplates I use reduced head #3 rivets. It only takes about 15 turns with a speed deburring tool to create the countersink. Even in 0.032, there's some meat left in the hole.

bpattonsoa

Well Known Member

Vans says, in Section 5, that reduced head nutplates (NAS1097) may be used. Every nutplate in my -10 uses a reduced head. I set up a microstop csk for them (I have four) and never changed it. As stated earlier, you can csk with a few spins of a deburring tool.

For some reason, ACS and others do not stock them. I got mine from Summit Racing. The most common is the -3-3.5 and the -3-4, but Summit does not stock the -3.5 any more. Just Google it. Get more than .1 lb., a -10 needs at least twice that of -3.5 and .1 of the -3 and -4.

For some reason, ACS and others do not stock them. I got mine from Summit Racing. The most common is the -3-3.5 and the -3-4, but Summit does not stock the -3.5 any more. Just Google it. Get more than .1 lb., a -10 needs at least twice that of -3.5 and .1 of the -3 and -4.

Last edited:

For some reason, ACS and others do not stock them. I got mine from Summit Racing.

You can also get them from Van's, but for some reason they don't sell them through the web site. You have to call or send an email. I bought a small supply of each size about a year ago from them.

flion

Well Known Member

Guys, this is not about the rivets attaching the nutplate. This is a technique for countersinking for the screws. As it happens, with the nutplate riveted in place, a #40 piloted countersink will center in a #6 nutplate and a #30 piloted countersink will center in a #8 nutplate. You can then use those piloted countersinks to countersink for the screw holes (not the rivet holes). When I did this, I took some scrap material the same thickness as the skin (for the wing) that would be the top layer over the nutplate. I drilled and dimpled for the screw and then used it as a depth gauge to set the countersink; it was deep enough when the dimpled gauge lay flat over the nutplate. Yes, you can countersink those deeper later, if you can get your countersink on them. I'm not sure that's going to be possible once the fuselage parts are assembled (I'd have to go look at my hangar to be sure). It's pretty easy to do now, so why not?

longranger

Well Known Member

Guys, this is not about the rivets attaching the nutplate. This is a technique for countersinking for the screws....

I got that Patrick, but post #5 does mention countersinking for nutplate rivets.

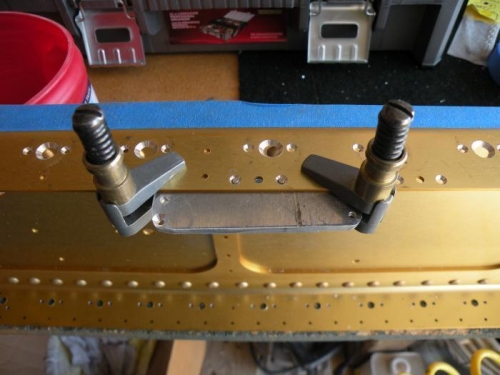

As far as countersinking for screws, I was concerned about damaging the nutplate threads, so I made a jig to center a countersink pilot on an unoccupied screw hole pre punched for a nutplate.:

Like many others, I also made dimple coupons of various sizes to aid in setting the countersink depth.

Last edited: