Resurrecting this thread to ask "how to get the plunger out of the hole?" I have taken out the plug and the spring but the plunger is stuck and/or held down by gravity. The side of the plunger is visible through the hole in the accessory case in the centre of the housing for the pressure screen or filter adapter.

My magnetic pickup tool won't fit down the plunger hole but maybe compressed air in one of the ports will blow the plunger out?

Thanks for any hints!

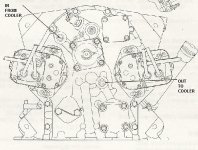

Disconnect the oil cooler hose at the port marked "out to cooler". Shoot compressed air into the port. It will probably pop the plunger up, at least until the air can escape through the bypass port (hold a rag over it, as it may spit oil). Freed up, the magnet may then work.

If air doesn't move it, hydraulic pressure will, but let's try a shot of air first.

Ca