rcsilvmac

Well Known Member

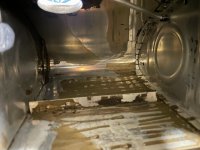

I have over 200 hours on my RV-6A that I purchased 4 years ago. If you inspect my gas tanks by looking in the fuel filler hole, they look pristine, with some sealer around the edges of the ribs and braces. I knew enough to be wary of tank sloshing but my inspections showed no signs of sloshing.

This weekend I removed my tanks (again) since I have a few persistent leaks. Upon inspection it was clear it was coming from the fuel tank sender cover. Whew...I am not looking forward to cutting 5" holes in my tank...

We remove the fuel sender cover and when I look in the tank, I see something that looks and feels like brown paper. This paper is flapping around and has some stringers starting to develop. See the pictures.

My question - is this slosh? Why would it not be visible on the inside compartment of the tank (where fuel filler is)? Would there be a reason the builder would have sloshed just the outside compartment?

Of course I need to remove all this - so I am moving forward on cutting access holes. Will research forum on best method to get this out of my tanks.

Thanks

This weekend I removed my tanks (again) since I have a few persistent leaks. Upon inspection it was clear it was coming from the fuel tank sender cover. Whew...I am not looking forward to cutting 5" holes in my tank...

We remove the fuel sender cover and when I look in the tank, I see something that looks and feels like brown paper. This paper is flapping around and has some stringers starting to develop. See the pictures.

My question - is this slosh? Why would it not be visible on the inside compartment of the tank (where fuel filler is)? Would there be a reason the builder would have sloshed just the outside compartment?

Of course I need to remove all this - so I am moving forward on cutting access holes. Will research forum on best method to get this out of my tanks.

Thanks