wirejock

Well Known Member

This stuff makes me crazy.

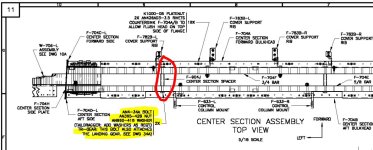

Lost a wrench this morning. Hours later, it's been found.

I am fanatical about FOD. If I drop so much as one of those tiny rod bearing washers, I won't let it go. Eventually every item is found. I've actually vacuumed and sifted the dirt before.

I suspect it would have lived there just fine but I'll sleep better now.

Lost a wrench this morning. Hours later, it's been found.

I am fanatical about FOD. If I drop so much as one of those tiny rod bearing washers, I won't let it go. Eventually every item is found. I've actually vacuumed and sifted the dirt before.

I suspect it would have lived there just fine but I'll sleep better now.