Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fixing broken RV7A leg fairing

- Thread starter maxmirot

- Start date

wirejock

Well Known Member

Flange clamp

Difficult to describe but I made a clamp. The finger thing didn't feel like a solid long term solution.

Photo explains it pretty well. Two screws inboard and two outboard hold the fairing to the clamp. There's one other hole inboard to adjust the breeze clamp. Once it's all adjusted, the fairing comes off or on with the four screws.

Final itteration has the nutplates off set so they clear each other. I made four before I was happy.

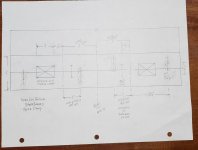

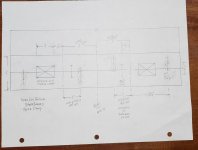

Drawing should be the final.

Difficult to describe but I made a clamp. The finger thing didn't feel like a solid long term solution.

Photo explains it pretty well. Two screws inboard and two outboard hold the fairing to the clamp. There's one other hole inboard to adjust the breeze clamp. Once it's all adjusted, the fairing comes off or on with the four screws.

Final itteration has the nutplates off set so they clear each other. I made four before I was happy.

Drawing should be the final.

Richard Connell

Well Known Member

Those leg fairings get absolutely punished in service.

If you fix them solidly something will just break.

You only need something to stop them twisting (the intersection fairings top and bottom does this) and something to stop them sliding up and down.

In reality depending on a few factors you may not even need anything to stop the motion up and down the leg.

A hose clamp tab at the top is more than sufficient. Make sure the bottom is free to float. One end only.

In short I’d make sure that it matches the plans. Sounds like your original setup (tab at the bottom) is non standard

If you fix them solidly something will just break.

You only need something to stop them twisting (the intersection fairings top and bottom does this) and something to stop them sliding up and down.

In reality depending on a few factors you may not even need anything to stop the motion up and down the leg.

A hose clamp tab at the top is more than sufficient. Make sure the bottom is free to float. One end only.

In short I’d make sure that it matches the plans. Sounds like your original setup (tab at the bottom) is non standard

Last edited:

sahrens

Well Known Member

Shamelessly copied

I copied Larry’s design with a few modifications for a tail wheel aircraft. Works so much better than the original clamping fiberglass tabs design.

Difficult to describe but I made a clamp. The finger thing didn't feel like a solid long term solution.

Photo explains it pretty well. Two screws inboard and two outboard hold the fairing to the clamp. There's one other hole inboard to adjust the breeze clamp. Once it's all adjusted, the fairing comes off or on with the four screws.

Final itteration has the nutplates off set so they clear each other. I made four before I was happy.

Drawing should be the final.

View attachment 44486

View attachment 44487

I copied Larry’s design with a few modifications for a tail wheel aircraft. Works so much better than the original clamping fiberglass tabs design.

wirejock

Well Known Member

Visit

Sure, I remember. Come on up.

Hey Larry, Greg Sokoloski, Mikes brother. Not sure how your clamp works. Need to make another visit up there to check on this. Back in 9A getting my skills developed.

Sure, I remember. Come on up.

wirejock

Well Known Member

Leg fairing clamp

I can't take credit. It's another builder's idea.

Credit to Mike Bullock and Don Pansier.

Here's a photo of the finished, mounted side clamp

Lots of ways to skin this so here's a couple tips for this one.

It's made from .032". Notice in the photo and drawing, the nutplates are offset fore/aft so the don't hit each other inside. The outboard holes are lower than the inboard holes. The left and right clamps are installed so the side with the lower holes are outboard. Reason is it's easier to put a screwdriver on the outboard screws. The breeze clamp is oriented so the screw is accessible from inboard. I had to make several to figure all that out! My wheels turn slow.

Fab the clamp. The final version has the top, aft corner trimmed off. Slip it in the fairing. Drill the screw holes and the breeze clamp access hole.

Move it to the leg. Cleko the fairing to the clamp to align the nutplates to the holes. Screw the fairing. Adjust position and tighten the breeze clamp. If the fairing needs to come off, just remove the screws. The clamp stays in place.

I can't take credit. It's another builder's idea.

Credit to Mike Bullock and Don Pansier.

Here's a photo of the finished, mounted side clamp

Lots of ways to skin this so here's a couple tips for this one.

It's made from .032". Notice in the photo and drawing, the nutplates are offset fore/aft so the don't hit each other inside. The outboard holes are lower than the inboard holes. The left and right clamps are installed so the side with the lower holes are outboard. Reason is it's easier to put a screwdriver on the outboard screws. The breeze clamp is oriented so the screw is accessible from inboard. I had to make several to figure all that out! My wheels turn slow.

Fab the clamp. The final version has the top, aft corner trimmed off. Slip it in the fairing. Drill the screw holes and the breeze clamp access hole.

Move it to the leg. Cleko the fairing to the clamp to align the nutplates to the holes. Screw the fairing. Adjust position and tighten the breeze clamp. If the fairing needs to come off, just remove the screws. The clamp stays in place.

Last edited: