I know this has been hashed around in the past. I’m trying to decide what external power plug to put on the 10. I know the standard is heavy, but everyone has one. I know Piper is lighter and small but will power be available if I really need it. My plane is very electrical dependent and jump starting is going to be a bad practice. However most daily use will be a trickle charge. I just don’t want to be stuck somewhere. Let me know which way y’all decide to go.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

External Power

- Thread starter 50Pesos

- Start date

Carl Froehlich

Well Known Member

Yep - many posts on this. I’ll just repeat what I have done for 20+ years.

I have a 15 amp switch breaker on the panel labeled “Shore Power”. It has a short pigtail on it with a Molex connector that gets tuck up behind the panel when not in use.

For hangar flying and such, I connect a regulated power supply (never a battery charger) to the pigtail and power up the plane. I set the power supply output voltage between 13.8 and 14.2vdc, usually starting at the lower voltage to see the what the battery is drawing, then bump up the output voltage to 14.2 (normal alternator output voltage) as the batteries catch up. In the meantime I’m doing whatever I need with the avionics.

The panel draws ~10 amps with everything running.

I tend to use this power supply perhaps twice a year.

My rules:

- Never jump start. If you have a flat battery you have most likely caused damage (as in your reserve electrical capacity is degraded). Replace abused batteries.

- Never use any trickle charger, battery minder, battery tender or such. My batteries last six years then longer in the tractors and such that they go into after the plane. I replace one battery (of two) every three years.

- Never run avionics on a battery charger.

Carl

I have a 15 amp switch breaker on the panel labeled “Shore Power”. It has a short pigtail on it with a Molex connector that gets tuck up behind the panel when not in use.

For hangar flying and such, I connect a regulated power supply (never a battery charger) to the pigtail and power up the plane. I set the power supply output voltage between 13.8 and 14.2vdc, usually starting at the lower voltage to see the what the battery is drawing, then bump up the output voltage to 14.2 (normal alternator output voltage) as the batteries catch up. In the meantime I’m doing whatever I need with the avionics.

The panel draws ~10 amps with everything running.

I tend to use this power supply perhaps twice a year.

My rules:

- Never jump start. If you have a flat battery you have most likely caused damage (as in your reserve electrical capacity is degraded). Replace abused batteries.

- Never use any trickle charger, battery minder, battery tender or such. My batteries last six years then longer in the tractors and such that they go into after the plane. I replace one battery (of two) every three years.

- Never run avionics on a battery charger.

Carl

rocketman1988

Well Known Member

Yep - many posts on this. I’ll just repeat what I have done for 20+ years.

I have a 15 amp switch breaker on the panel labeled “Shore Power”. It has a short pigtail on it with a Molex connector that gets tuck up behind the panel when not in use.

For hangar flying and such, I connect a regulated power supply (never a battery charger) to the pigtail and power up the plane. I set the power supply output voltage between 13.8 and 14.2vdc, usually starting at the lower voltage to see the what the battery is drawing, then bump up the output voltage to 14.2 (normal alternator output voltage) as the batteries catch up. In the meantime I’m doing whatever I need with the avionics.

The panel draws ~10 amps with everything running.

I tend to use this power supply perhaps twice a year.

My rules:

- Never jump start. If you have a flat battery you have most likely caused damage (as in your reserve electrical capacity is degraded). Replace abused batteries.

- Never use any trickle charger, battery minder, battery tender or such. My batteries last six years then longer in the tractors and such that they go into after the plane. I replace one battery (of two) every three years.

- Never run avionics on a battery charger.

Carl

Never use the word never...

As for jump starting, I agree, especially in an electrically dependent airplane.

I use battery tenders on virtually all my power equipment without any issue. This doesn't really apply to my -10 with EarthX batteries, though the Optimate charger indicates that it can be done.

I have dual ETX900s in my -10 and use the recommended Optimate charger. The charger also has a "power supply" mode, and that is what I use for avionics work exclusively. So, I AM technically using a charger to power my avionics in the hangar.

MacCool

Well Known Member

I have dual PC680 batteries on the firewall with a short pigtail of 20 gauge wire with a molex connector that's accessible through the oil door on the cowl when open. Most of the time in the hangar the airplane is on an Odyssey float charger to keep the batteries up. Because that charger has a pulsed "de-sulfation" mode part of the time (rumor has it that that is bad for avionics), I also have a regulated power supply that I plug in if and when I'm tinkering with the avionics (database and other software updates etc). I also use that molex pigtail to power a vent fan that I slap into the oil-door opening on landing/tying down for short turn-around stops to vent the under-cowl area for cooling and therefore less problematic hot-starting. I don't use that pigtail for jump starting (I wouldn't jump start my airplane).

In this area, I have a lot of seasonal rolling stock that I routinely keep on float chargers (Battery Tenders) for parts of the year. I'm a big believer in their contribution to maximizing lead-acid battery health and longevity. Between garages, workshop, and hangar, I must have 10 or 12 of the things and have found them reliable and effective.

In this area, I have a lot of seasonal rolling stock that I routinely keep on float chargers (Battery Tenders) for parts of the year. I'm a big believer in their contribution to maximizing lead-acid battery health and longevity. Between garages, workshop, and hangar, I must have 10 or 12 of the things and have found them reliable and effective.

Last edited:

EarthX Specific Answer

For my RV 10, (2x EarthX) I just put two pigtails with SAE connectors on the rear wall of the baggage compartment, connected with an inline fuse to the batteries.

That connector connects directly to the optimate charger. The charger is pretty light and if you travel with it you are independent. The weight of the big connector, the contactor and the #2 wire add up.

10 Amps (their big charger) will get you going pretty quickly, waiting an hour to takeoff isn't really all that uncommon in world of small airplane scheduling. You will feel a lot better about the battery, than if you just hit an empty one with a ton of amps and blast off into the wild blue. (Replacing the battery is good advice here).

SAE connectors are available in all forms on amazon.

Like Bob, I have and do run my avionics on the optimate (again Lithium version only), but would never run them on a lead acid charger.

If you have any doubt, avionics are expensive. Run them on the battery and charge after.

For my RV 10, (2x EarthX) I just put two pigtails with SAE connectors on the rear wall of the baggage compartment, connected with an inline fuse to the batteries.

That connector connects directly to the optimate charger. The charger is pretty light and if you travel with it you are independent. The weight of the big connector, the contactor and the #2 wire add up.

10 Amps (their big charger) will get you going pretty quickly, waiting an hour to takeoff isn't really all that uncommon in world of small airplane scheduling. You will feel a lot better about the battery, than if you just hit an empty one with a ton of amps and blast off into the wild blue. (Replacing the battery is good advice here).

SAE connectors are available in all forms on amazon.

Like Bob, I have and do run my avionics on the optimate (again Lithium version only), but would never run them on a lead acid charger.

If you have any doubt, avionics are expensive. Run them on the battery and charge after.

Last edited:

Like DerekS, I have two EarthX batteries in the tail that I connect with an SAE plug located on the aft baggage compartment wall inside the baggage door for easy access. I have a dual pole relay that allows me to use one SAE plug, and either apply power to the main or both batteries for charging via selector button.

I have a 12V/24A ground power unit that I use to keep the system charged, but also for running the avionics in the hangar.

If I'm at somewhere other than my home airport and my main battery is dead, well, that's why I have the aux battery. With the main battery contactor open, I would shut my aux battery contactor and start the airplane. I also carry an SAE pigtail in my "away bag" that can be used with a set of jumper cables to do ground charging if needed.

I have had an experience many years ago where I used 20' jumper cables (ground and then positive to starter contactor post, which was on the firewall), on a dark and stormy day no less, to jump start my '61 Debonair from an airport car. I remember a wave breaking up on to the rocks as the engine fired over. It worked, but wow, dangerous and crazy.

With access to a 12V charger, you can recharge your battery in about an hour - at least sufficient to start the airplane (and if that's not true - you probably need a new one and shouldn't fly with the bad one...), which is my preference in the event of dead battery, vice attempting to jump start the airplane.

I have a 12V/24A ground power unit that I use to keep the system charged, but also for running the avionics in the hangar.

If I'm at somewhere other than my home airport and my main battery is dead, well, that's why I have the aux battery. With the main battery contactor open, I would shut my aux battery contactor and start the airplane. I also carry an SAE pigtail in my "away bag" that can be used with a set of jumper cables to do ground charging if needed.

I have had an experience many years ago where I used 20' jumper cables (ground and then positive to starter contactor post, which was on the firewall), on a dark and stormy day no less, to jump start my '61 Debonair from an airport car. I remember a wave breaking up on to the rocks as the engine fired over. It worked, but wow, dangerous and crazy.

With access to a 12V charger, you can recharge your battery in about an hour - at least sufficient to start the airplane (and if that's not true - you probably need a new one and shouldn't fly with the bad one...), which is my preference in the event of dead battery, vice attempting to jump start the airplane.

Last edited:

. My plane is very electrical dependent and jump starting is going to be a bad practice. However most daily use will be a trickle charge. I just don’t want to be stuck somewhere. Let me know which way y’all decide to go.

Any charger can conceal a battery issue. "Modern" batteries do a good job of holding their change for weeks/months. Fly your aircraft. If a battery won't start it, I'd stay on the ground until rectified. Also, much better to discover related problems at your home field.

My $.02 but there are strong opposing opinions here.

KatanaPilot

Well Known Member

Another possibility

We built a small panel mounted on the engine mount and accessed through a door in the cowling.

Both of our ETX-900’s are mounted forward of the sub panel, so close by. The panel has ports for the two batteries (Optimate charger as recommended by other posters), a 30 amp Anderson power pole connector (for powering up avionics, etc. using a regulated power supply) and a 110 VAC connector to power the Tanis engine pre-heater.

We are also electrically dependent and my intention is to never jump start the plane, hence the Anderson versus a Piper or Cessna style external power port.

We built a small panel mounted on the engine mount and accessed through a door in the cowling.

Both of our ETX-900’s are mounted forward of the sub panel, so close by. The panel has ports for the two batteries (Optimate charger as recommended by other posters), a 30 amp Anderson power pole connector (for powering up avionics, etc. using a regulated power supply) and a 110 VAC connector to power the Tanis engine pre-heater.

We are also electrically dependent and my intention is to never jump start the plane, hence the Anderson versus a Piper or Cessna style external power port.

PilotjohnS

Well Known Member

Just me

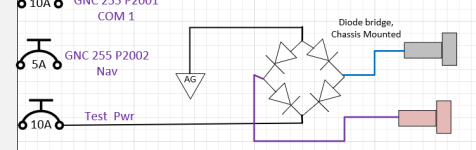

I have a circuit breaker on the panel labeled "Test Power". it is wired to a diode bridge and a set of banana jacks on the sub panel. When I want to power up the panel, for say software updates, I pull the test circuit breaker, plug in an external power supply to the banana jacks, set the voltage on the external supply, leave the master switch off, and then push in the test circuit breaker, and the panel comes alive. The only issue is the voltage on the external power supply needs to be 2 volts above the desired panel voltage due to the drop in the diode bridge. The diode bridge allows me to plug the banana jacks in any which way, and the polarity of the power to the panel is always correct. I am thinking of switching out the diode bridge with a relay bridge instead, thou.

I have a circuit breaker on the panel labeled "Test Power". it is wired to a diode bridge and a set of banana jacks on the sub panel. When I want to power up the panel, for say software updates, I pull the test circuit breaker, plug in an external power supply to the banana jacks, set the voltage on the external supply, leave the master switch off, and then push in the test circuit breaker, and the panel comes alive. The only issue is the voltage on the external power supply needs to be 2 volts above the desired panel voltage due to the drop in the diode bridge. The diode bridge allows me to plug the banana jacks in any which way, and the polarity of the power to the panel is always correct. I am thinking of switching out the diode bridge with a relay bridge instead, thou.

Attachments

Last edited:

simple but useful

I had the same want as you so I just put a fused cigarette lighter socket (yes I'm showing my age), on the panel. it is directly connected to the battery so it is the only thing that doesn't go through Master, or Avionics switches. I plug my battery tender into it when the plane is in the hanger, and when I'm flying I have a 12V source.

Works great for me!

I had the same want as you so I just put a fused cigarette lighter socket (yes I'm showing my age), on the panel. it is directly connected to the battery so it is the only thing that doesn't go through Master, or Avionics switches. I plug my battery tender into it when the plane is in the hanger, and when I'm flying I have a 12V source.

Works great for me!

I know this has been hashed around in the past. I’m trying to decide what external power plug to put on the 10. I know the standard is heavy, but everyone has one. I know Piper is lighter and small but will power be available if I really need it. My plane is very electrical dependent and jump starting is going to be a bad practice. However most daily use will be a trickle charge. I just don’t want to be stuck somewhere. Let me know which way y’all decide to go.

So we’ve got five airplane in our family “fleet”, and all five have different external power connections because….well….that’s how they evolved. When I built my -8, I figured it was my “forever” airplane (little did I know….), and having grown up in the frozen north, I wanted to be able to do a battery assist if I was visiting home in the winter. When it gets really cold, why kill your only battery cranking the motor if you can have a start cart take the load? So I installed the Piper jack as described by Bob Knuckolls (they are far cheaper than the Cessna plug because they are used on 18-Wheelers…heavier, but cheap!). I’ve ben very happy with it, and carry my own cable on cross-country trips in winter - just in case.

Louise’s RV-6 has an Andersen plug tucked up under the panel, connected to the battery (between the rudder cables) because it was easy to put in when we were re-doing the panel. I wouldn’t jump start with it because the cable has to go over the longeron, but it would handle the load. The RV-3 has a Cannon plug hidden inside the cheek cowl compartment that connects to the battery for charging and/or avionics power on the ground (using a shop DC power supply) - not big enough for start power. The Tundra has an EarthX battery charger jack under the cowl (right on the battery box) for Optimate charging. That can also be used with my shop power supply if needed for Avionics work. And the jet has a 24 volt connector for its own dedicated charger - no way it would support the power required to spoon the engine for a start - just top-up charging and external power for maintenance.

So choosing external power really comes down to what you want to do and where you live. If you have the need to help your battery on a cold-weather start, then a Piper jack isn’t a bad idea. For all other uses, you can probably get by with a 10-Amp connector of some sort for external shop power/charging.

Paul