Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

elevator trim servo

- Thread starter cholladay

- Start date

sstellarv10

Well Known Member

That is the correct servo. I have the same one and I didn't have any travel problems.

Wayne Gillispie

Well Known Member

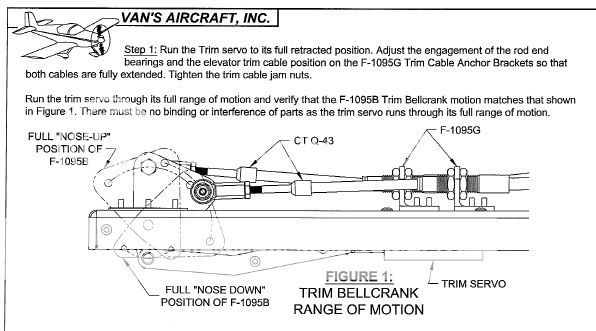

Check the triangle shaped piece especially...

and make sure everything matches diagrams. I did not have any problem with travel until I connected cables. Very poor instructions in this area. I ended up figuring it all out and noted all thread amounts on each side of brackets in front and rear of cables as well as rod ends if you need that info. Whatever you do, don't rivet the rear brackets on like I did. Use #6 screws and nut plates. It will make it much easier to make adjustments at elevator end. Also use a 1/2" drum sander on forward brackets where cables touch to provide 1/32" clearance. Good luck.

and make sure everything matches diagrams. I did not have any problem with travel until I connected cables. Very poor instructions in this area. I ended up figuring it all out and noted all thread amounts on each side of brackets in front and rear of cables as well as rod ends if you need that info. Whatever you do, don't rivet the rear brackets on like I did. Use #6 screws and nut plates. It will make it much easier to make adjustments at elevator end. Also use a 1/2" drum sander on forward brackets where cables touch to provide 1/32" clearance. Good luck.

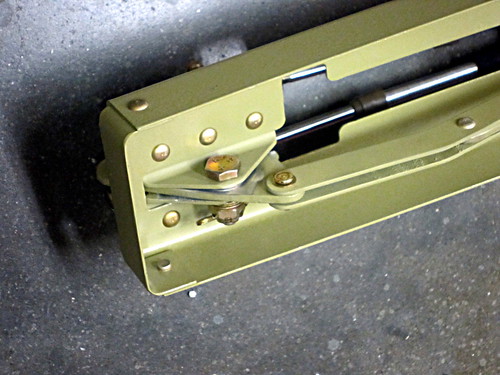

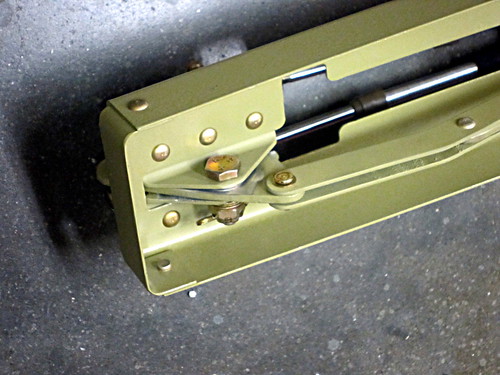

The 12A is the right servo. Here's some photos of my install for you to compare against:

Elevator Trim Push-Pull Cables, Nose-Up by Mouser NerdBot, on Flickr

Elevator Trim Push-Pull Cables by Mouser NerdBot, on Flickr

Elevator Trim Bellcrank Underside by Mouser NerdBot, on Flickr

Hope that helps!

Elevator Trim Push-Pull Cables, Nose-Up by Mouser NerdBot, on Flickr

Elevator Trim Push-Pull Cables by Mouser NerdBot, on Flickr

Elevator Trim Bellcrank Underside by Mouser NerdBot, on Flickr

Hope that helps!

Mouser

OK in your first photo according to the diagrams from Vans you have to much rotation of the bell crank. Vans shows the cable closest to you in the photo to be horizontal to the mounting plate. Your photo ,which is also looks like mine goes below the point that the instruction call out for Max. travel.

OK in your first photo according to the diagrams from Vans you have to much rotation of the bell crank. Vans shows the cable closest to you in the photo to be horizontal to the mounting plate. Your photo ,which is also looks like mine goes below the point that the instruction call out for Max. travel.

jerseypilot83

Active Member

I had the same problem with my

Rv10 elevator trim. I was staring at the plans for several hours. Though my one cable was too far down because it didn’t match the plans. When I read about the cables being in neutral position with a shadow of the positions on arm …. It all makes sense. Sometimes we overthink things.

Rv10 elevator trim. I was staring at the plans for several hours. Though my one cable was too far down because it didn’t match the plans. When I read about the cables being in neutral position with a shadow of the positions on arm …. It all makes sense. Sometimes we overthink things.

I had the same problem with my

Rv10 elevator trim. I was staring at the plans for several hours. Though my one cable was too far down because it didn’t match the plans. When I read about the cables being in neutral position with a shadow of the positions on arm …. It all makes sense. Sometimes we overthink things.

The instructions here are very poor and if you follow them, you may end up with the two tabs in an assymetric condition at neutral. Tim has a good set of instructions on his site for setting it up a different way that leaves the two tabs perfectly aligned at neutral. Suggest reviewing it.

DavidP2020

Well Known Member

The instructions here are very poor and if you follow them, you may end up with the two tabs in an assymetric condition at neutral. Tim has a good set of instructions on his site for setting it up a different way that leaves the two tabs perfectly aligned at neutral. Suggest reviewing it.

Could you please add a link or name of the build log site?

Thanks!

Could you please add a link or name of the build log site?

Thanks!

<myrv10.com> I think you need a password for some parts (?). Contact Tim Olson (“TimO” on vaf).

Last edited:

jerseypilot83

Active Member

Elevator trim servo wiring

I was wondering what is the best type of wire to run my RA actuator servo elevator trim to the panel…. I heard it’s not too big of deal and was going to run thermostat 5 conductor wire 20 or 22awg stranded?? Thoughts anyone. Does shielding become mandatory here? And can the black wire be grounded to a AN3 bolt near the aft?

Thanks all

I was wondering what is the best type of wire to run my RA actuator servo elevator trim to the panel…. I heard it’s not too big of deal and was going to run thermostat 5 conductor wire 20 or 22awg stranded?? Thoughts anyone. Does shielding become mandatory here? And can the black wire be grounded to a AN3 bolt near the aft?

Thanks all

I was wondering what is the best type of wire to run my RA actuator servo elevator trim to the panel…. I heard it’s not too big of deal and was going to run thermostat 5 conductor wire 20 or 22awg stranded?? Thoughts anyone. Does shielding become mandatory here? And can the black wire be grounded to a AN3 bolt near the aft?

Thanks all

While I do a fair amount of frame grounding, I do not use it for potentiometers like that found in that servo, as they are typically sensitive. The ground on a servo is not for the motor, but for the potentiometer.