It all depends really on how many amps you need.

I have found so far in the tailcone and wing wiring that the dsubs seemed like a good idea but are very bulky, and not easy to mount the connector anywhere - need a big and weird shaped hole. Basically only good for signal and avionics wiring anyway due to contact amps rating. You need a dsub crimper but they are cheap. I’ve used dsub pins with no connector in the elevator to join the trim motor to the wiring.

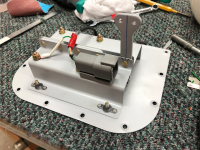

The deutsch dtm are a better - up to 7.5 amps. Again though hard to mount the connector. You can get little plastic clips which you can bolt on, but the hole is way too big. They are a PIA to get the connector off the clip once installed. I’ve riveted the clips on using a flush pull rivet, but they connect to the male side of the connector which is a little annoying. Photo of how I used a dtm to power my roll trim servo. You can crimp the pins using a dsub crimper but they don’t take dsub pins - they take their own pins which look a lot like dsub but are not the same.

Finally there are cpc. I like these. They are easy to mount in a circular hole and come in 2 series. They come in “reverse sex” which allow the female to be the panel mounted connector. Series 2 take dsub pins and therefore only signal and low power avionics - can crimp with a dsub crimper. Series 1 take power pins up to 13 amps and you crimp with a molex style crimper. Photo of how I’ve used these on my wing connectors.

I was totally bamboozled by all the choices so made a reference document you may find useful:

https://drive.google.com/file/d/1cw7OPO0I_RDc_H0VNA7YjZ_BSVK-W-RA/view