So the next iteration of the 3D printed EarthX Battery mount for the RV-10 (or other) is complete. Wally was able to double the design for a single battery, rotate it 90 degrees and do a base mount that with just a small amount of cutting to the aluminum base provided by vans provides a solid lock in of the battery with minimal work. As with the single, the .stl files are available for free if you would like to do the roughly 60 hour print yourself. If you need one printed then Wally is again willing do so for a modest fee to cover his time, materials, and shipping. These are printed with ABS material. Feel free to PM me your email for the file or contact Wally at [email protected] if you need a print.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EarthX Dual Battery Mount (3D Print)

- Thread starter mulde35d

- Start date

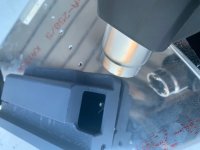

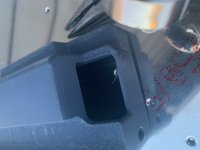

I did a test fit today of the battery box on an actual ETX900 battery rather than the empty case that I had previously from EarthX. Much to our surprise the actual battery came out .125" thinner in width than the empty battery case. This has me scratching my head as I was under the impression the empty case was the same empty case they normally fill with battery material.

I have sent a note to EarthX, but does anyone know if they changed the width of their ETX batteries recently? If so, when?

Good news is that even with the smaller width, the battery cap still holds the battery snugly since the length is the same and the narrow edges on the top of the battery stayed the same dimension. The bases will need a small shim of .125 aluminum. Wally is redesigning the pieces as we speak to compensate for the reduced width. Will let you know when we have new .STL files made

I have sent a note to EarthX, but does anyone know if they changed the width of their ETX batteries recently? If so, when?

Good news is that even with the smaller width, the battery cap still holds the battery snugly since the length is the same and the narrow edges on the top of the battery stayed the same dimension. The bases will need a small shim of .125 aluminum. Wally is redesigning the pieces as we speak to compensate for the reduced width. Will let you know when we have new .STL files made

David Paule

Well Known Member

Jon, is it correct that you plan to use a plastic battery box for an unevented EarthX battery that's inside the fuselage?

I'd expect that at least you'd want the vented version.

Also, if the case melts, could it potentially reharden around a flight control?

Dave

I'd expect that at least you'd want the vented version.

Also, if the case melts, could it potentially reharden around a flight control?

Dave

Jon, is it correct that you plan to use a plastic battery box for an unevented EarthX battery that's inside the fuselage?

I'd expect that at least you'd want the vented version.

Also, if the case melts, could it potentially reharden around a flight control?

Dave

Absolutely, the tailcone of the RV10 is generally not considered in the fuselage as has been discussed numerous times in other threads. Also, if the ABS case reaches its melting point of 200+ degrees F then I am much more worried about the fire than the pliable plastic dripping down into the bottom of the aircraft. I would not be convinced that enough ABS is present and able to fall through the center hole onto the elevator control rod to cause any sort of blockage (only about 1oz of material under the battery and near the holes). Once again, the fire would be a bit more critical.

David Paule

Well Known Member

I'm building a -3B, not a -10, and mine uses a smaller non-vented EarthX battery than yours. I wrote Cathy and asked her how hot it would get in the worst case, and she said it would be in excess of 300 F. I don't remember the exact temperature, and can't find her response - I lost many of my emails in a computer issue a while back.

I placed my battery aft of the FWF and outboard of the cockpit, in one of the cowl cheek extensions.

Your battery box is quite nicely designed, except for that one issue. How hard would it be to vent it overboard and arrange for a positive pressure air flow through it? Or at a minimum, allow the 900-VNT battery to fit and drain properly. That model EarthX battery has an integral vent. Still, without internal airflow to the box, I'd worry about a melt-down.

The metal battery box on my C180 carries a non-lithium battery and has no blast tube. But it does have an overboard drain which I expect was intended back in 1955 to allow escaping battery acid to drain.

Dave

I placed my battery aft of the FWF and outboard of the cockpit, in one of the cowl cheek extensions.

Your battery box is quite nicely designed, except for that one issue. How hard would it be to vent it overboard and arrange for a positive pressure air flow through it? Or at a minimum, allow the 900-VNT battery to fit and drain properly. That model EarthX battery has an integral vent. Still, without internal airflow to the box, I'd worry about a melt-down.

The metal battery box on my C180 carries a non-lithium battery and has no blast tube. But it does have an overboard drain which I expect was intended back in 1955 to allow escaping battery acid to drain.

Dave

dmattmul

Well Known Member

Vented EarthX batteries

When I looked at using the vented model in my 10, EarthX did not (Still does not) have a vented 1200 (They only have vented for the 900) so I talked to EarthX and they were very comfortable having a non-vented battery(s) in the tail cone of the RV-10. They felt there would more than enough airflow to not be a concern. I've been using this chemistry in various vehicles for almost 20 years and EarthX (2 - 900's) in my 14 FWF for almost 5 years and comfortable with my decision.

Jon, is it correct that you plan to use a plastic battery box for an unevented EarthX battery that's inside the fuselage?

I'd expect that at least you'd want the vented version.

Also, if the case melts, could it potentially reharden around a flight control?

Dave

When I looked at using the vented model in my 10, EarthX did not (Still does not) have a vented 1200 (They only have vented for the 900) so I talked to EarthX and they were very comfortable having a non-vented battery(s) in the tail cone of the RV-10. They felt there would more than enough airflow to not be a concern. I've been using this chemistry in various vehicles for almost 20 years and EarthX (2 - 900's) in my 14 FWF for almost 5 years and comfortable with my decision.

I'm building a -3B, not a -10, and mine uses a smaller non-vented EarthX battery than yours. I wrote Cathy and asked her how hot it would get in the worst case, and she said it would be in excess of 300 F. I don't remember the exact temperature, and can't find her response - I lost many of my emails in a computer issue a while back.

I placed my battery aft of the FWF and outboard of the cockpit, in one of the cowl cheek extensions.

Your battery box is quite nicely designed, except for that one issue. How hard would it be to vent it overboard and arrange for a positive pressure air flow through it? Or at a minimum, allow the 900-VNT battery to fit and drain properly. That model EarthX battery has an integral vent. Still, without internal airflow to the box, I'd worry about a melt-down.

The metal battery box on my C180 carries a non-lithium battery and has no blast tube. But it does have an overboard drain which I expect was intended back in 1955 to allow escaping battery acid to drain.

Dave

ABS is an interesting material as it is a thermoplastic that starts to become pliable at 205 F, but when printed the print head generally needs to be at least 410 F to get it to truly "melt". At 300F I would bet it is soft, but not able to drip anywhere. By then I would also expect the battery management system to shut down the battery unless you have a true runaway in which case I would be more concerned with fire. I will take a test print and stick a 300F heat gun on it. Will see what happens

Testing

Testing complete:

Photo 1: 300F steady state

Photo 2: 300F twisting with pliers

Photo 3: 300F pressing with moderate thumb force

Photo 4: 400F steady state

Photo 5: 500F steady state

I would expect anything over 400F to be pliable, but their was very little sag present. Sagging really didn't start until 500F. For all of these I left the heat gun in place at 1/2" from the material for 3 minutes before starting to press or manipulate the ABS.

Testing complete:

Photo 1: 300F steady state

Photo 2: 300F twisting with pliers

Photo 3: 300F pressing with moderate thumb force

Photo 4: 400F steady state

Photo 5: 500F steady state

I would expect anything over 400F to be pliable, but their was very little sag present. Sagging really didn't start until 500F. For all of these I left the heat gun in place at 1/2" from the material for 3 minutes before starting to press or manipulate the ABS.

Attachments

Last edited:

So the next iteration of the 3D printed EarthX Battery mount for the RV-10 (or other) is complete. Wally was able to double the design for a single battery, rotate it 90 degrees and do a base mount that with just a small amount of cutting to the aluminum base provided by vans provides a solid lock in of the battery with minimal work. As with the single, the .stl files are available for free if you would like to do the roughly 60 hour print yourself. If you need one printed then Wally is again willing do so for a modest fee to cover his time, materials, and shipping. These are printed with ABS material. Feel free to PM me your email for the file or contact Wally at [email protected] if you need a print.

Private message sent! Great work on this. Very nice.

Thank you for sharing the design and exporting some .step files for CNC machining. I had these machined out of 6061-T6 Aluminium and finished with glass bead blasting. They're super sturdy, probably overly so, but fit the batteries like a glove!

The text couldn't be machined in, so they laser-cut it instead. They turned out pretty nice - though more expensive than I had planned (about 250). After working with the shop on these (I don't know much about CNC and had lots of beginner questions..) I felt bad backing out!

The text couldn't be machined in, so they laser-cut it instead. They turned out pretty nice - though more expensive than I had planned (about 250). After working with the shop on these (I don't know much about CNC and had lots of beginner questions..) I felt bad backing out!

Attachments

Jon,So the next iteration of the 3D printed EarthX Battery mount for the RV-10 (or other) is complete. Wally was able to double the design for a single battery, rotate it 90 degrees and do a base mount that with just a small amount of cutting to the aluminum base provided by vans provides a solid lock in of the battery with minimal work. As with the single, the .stl files are available for free if you would like to do the roughly 60 hour print yourself. If you need one printed then Wally is again willing do so for a modest fee to cover his time, materials, and shipping. These are printed with ABS material. Feel free to PM me your email for the file or contact Wally at [email protected] if you need a print.

Any mods for the vented battery?