PilotBrent

Well Known Member

http://https://dynonavionics.com/bulletins/104808-000-Rev-A-Tech-Service-Bulletin-SV-AP-PANEL.pdf

This SERVICE BULLETIN from Dynon was in part triggered by my experience in my E-LSA RV-12 on 7/26/2023 during my return from Oshkosh this year. The equipment failure led to an in flight emergency. I reported it both to Dynon and Vans - I am aware of other aircraft who experienced similar failures so it may not be as rare as the SB suggests. If you use one of this affected SV-AP-PANEL units in your aircraft, please take the SB seriously.

What appeared to be an intermittent failure of the AP Control Panel in flight led to an uncommanded full nose up trim movement during takeoff that could not be resolved with the trim control button on the RV-12 panel. I was able to successfully return to the airport & land although emergency equipment was activated by ATC given the high degree of difficulty I experienced in manuvering the aircraft in this configuration. Most pilots are very aware of actual aircraft crashes due to uncommanded/unexpected extreme trim configurations.

I completed an emergency fix at a remote airport in Canada and was able to fly the aircraft home to New Jersey with neutral trim. Upon notifying Dynon, they quickly provided a new/replacement SV-AP Panel. Dynon later informed me that they had been aware of some failures in early AP units, but for reasons I cannot understand, they had decided not to issue a warning or SB to aircraft owners relying on these early AP Control units.

Given the intermittent nature of the original failure I am not fully confident that a similar situation could not reoccur. Most importantly, I am concerned that an intermittent (or any) failure of the SV-AP Panel could prevent a pilot from manually activating the trim servo motor in an RV-12. I was not aware of this risk and I suspect most RV-12 pilots with a Dynon panel would also be very concerned about the possibility that a hardware and/or software failure with this Skyview accessory panel could 1) lead to a full and uncommanded nose up trim movement in flight especially when the autopilot is not even activated and 2) prevent the pilot from manually adjusting the trim to safely maintain aircraft control.

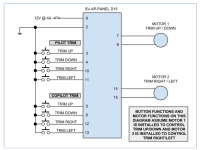

I have subsequently installed a bypass panel in my RV-12 that allows me switch off the AP PANEL and manually control the TRIM Servo should the AP PANEL similarly fail in future. That is the only way I am comfortable making longer cross country trips. This "fix" was also suggested to me by Van's, although I had already made the modification. (PS. Van's also informed me that RV-12is wiring is apparently not subject to this type of TRIM control failure.)

This SERVICE BULLETIN from Dynon was in part triggered by my experience in my E-LSA RV-12 on 7/26/2023 during my return from Oshkosh this year. The equipment failure led to an in flight emergency. I reported it both to Dynon and Vans - I am aware of other aircraft who experienced similar failures so it may not be as rare as the SB suggests. If you use one of this affected SV-AP-PANEL units in your aircraft, please take the SB seriously.

What appeared to be an intermittent failure of the AP Control Panel in flight led to an uncommanded full nose up trim movement during takeoff that could not be resolved with the trim control button on the RV-12 panel. I was able to successfully return to the airport & land although emergency equipment was activated by ATC given the high degree of difficulty I experienced in manuvering the aircraft in this configuration. Most pilots are very aware of actual aircraft crashes due to uncommanded/unexpected extreme trim configurations.

I completed an emergency fix at a remote airport in Canada and was able to fly the aircraft home to New Jersey with neutral trim. Upon notifying Dynon, they quickly provided a new/replacement SV-AP Panel. Dynon later informed me that they had been aware of some failures in early AP units, but for reasons I cannot understand, they had decided not to issue a warning or SB to aircraft owners relying on these early AP Control units.

Given the intermittent nature of the original failure I am not fully confident that a similar situation could not reoccur. Most importantly, I am concerned that an intermittent (or any) failure of the SV-AP Panel could prevent a pilot from manually activating the trim servo motor in an RV-12. I was not aware of this risk and I suspect most RV-12 pilots with a Dynon panel would also be very concerned about the possibility that a hardware and/or software failure with this Skyview accessory panel could 1) lead to a full and uncommanded nose up trim movement in flight especially when the autopilot is not even activated and 2) prevent the pilot from manually adjusting the trim to safely maintain aircraft control.

I have subsequently installed a bypass panel in my RV-12 that allows me switch off the AP PANEL and manually control the TRIM Servo should the AP PANEL similarly fail in future. That is the only way I am comfortable making longer cross country trips. This "fix" was also suggested to me by Van's, although I had already made the modification. (PS. Van's also informed me that RV-12is wiring is apparently not subject to this type of TRIM control failure.)