Geeking out on failing surfaces

I am not saying one can do an Engineering Investigation through a set of photos on VAF, but the photos suggest to me to keep an open mind about how this broke.

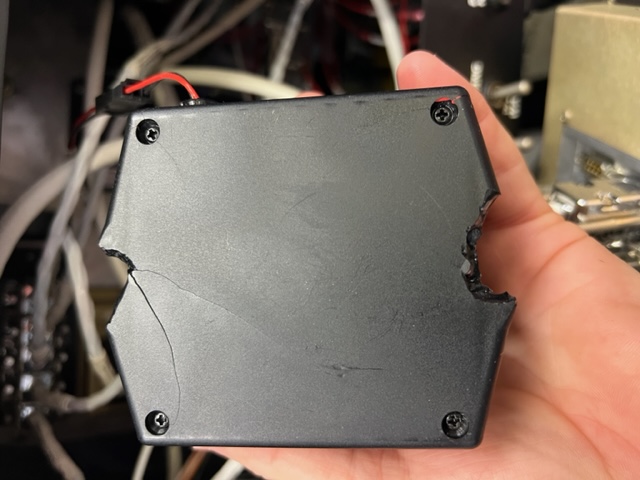

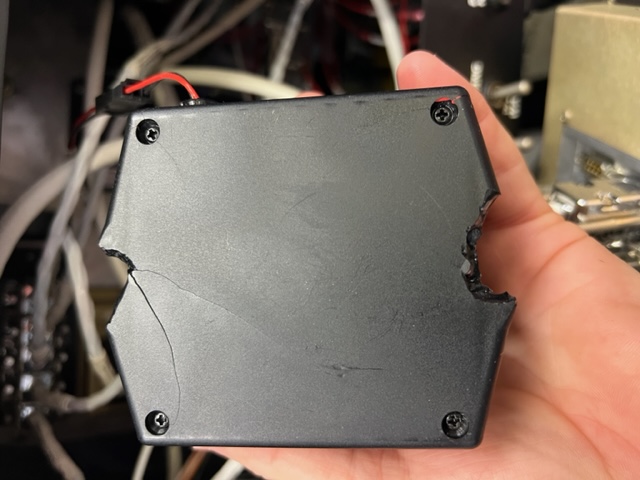

It looked like the OP was considering case swell as a failure mode.

We can assume this plastic is more ductile in nature than brittle at cabin temperatures, since that is usually the nature of thermoplastics. Ductile materials can fail in both a ductile and a brittle manner depending on how fast the failure happens.

Generally things break in an event overload, or over time by tiny overloads that progress through the material that we call fatigue cracking. Fatigue based failures are a sort of hybrid in appearance as they look like they combine both brittle and ductile modes.

In breakages it is often valuable to determine if the shear zone looks like a brittle or a ductile failure, considering the material and the type of loading plane at failure. (shear or tension, not too many compressive failures out there) For failures of ductile material in tension (most common) we look for a 90 degree parting face across stress lines for a brittle failure and a 45 degree face for a ductile failure (a ductile failure acts to convert tension to shear).

Ductile failures are slow rises in stress (thus strain) above the material's ultimate strength. Brittle failures in ductile material tend to be very rapid events. Think about the difference between pulling apart a blind rivet mandrel and breaking a piece of metal with a fast hammer blow, or breaking some glass. (Check out your pulled mandrels on your less expensive blind rivets, they have a 45 degree shear plane along the lines of pulled tension unless the manufacturer spent the time to design a brittle break zone)

The failure zones immediately around those attach points in the OP photo may be showing some 45 degree failure planes. Then there are some obvious cracks in the plastic that look like brittle failures or fatigue with classic 90 degree failure planes.

So if somebody suggested case swelling in this failure I would totally agree with looking further into that possibility. If the cracks immediately around those attach points were closer to a 90 degree failure plane I would lean more toward fatigue cracks initiated by stress concentration points created by tight fasteners.