Dugaru

Well Known Member

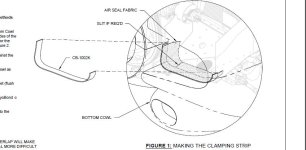

So my RV-9A, which I did not build, has baffling strips at the top and bottom of each cowl inlet. The baffling material is held on with aluminum clamping strips secured with screws and nutplates.

Today the top right assembly decided it did not want to go flying, and tried to exit the aircraft while I was taxiing! The aluminum clamping strip dropped on top of the alternator pulley, making a scraping noise that alerted me to some sort of problem. After decowling we quickly found the strip, with damage from contact with the pulley:

Two questions:

1. Is this a Vans part, or did my builder likely fabricate it? I can only find a strip for the bottom of the cowl opening, but I’m not good searching the Vans store.

2. What’s the best way to secure these assemblies? I don’t have a lot of confidence in screws/nutplates, since the screws apparently just worked their way loose.

Thanks for any suggestions!

Today the top right assembly decided it did not want to go flying, and tried to exit the aircraft while I was taxiing! The aluminum clamping strip dropped on top of the alternator pulley, making a scraping noise that alerted me to some sort of problem. After decowling we quickly found the strip, with damage from contact with the pulley:

Two questions:

1. Is this a Vans part, or did my builder likely fabricate it? I can only find a strip for the bottom of the cowl opening, but I’m not good searching the Vans store.

2. What’s the best way to secure these assemblies? I don’t have a lot of confidence in screws/nutplates, since the screws apparently just worked their way loose.

Thanks for any suggestions!