dhmoose

Well Known Member

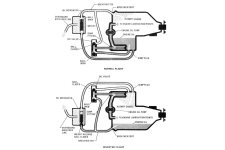

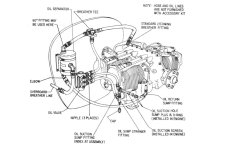

I recently purchased an RV-8 with a Christen inverted oil system. Problem is, the original owner has not gone inverted in ~16 years leading me to worry that the balls and seats within the oil valve and oil separator are corroded or filled with sludge. I understand that the ball in the separator is not removable or accessible but the ball in the oil valve is maintainable.

My question is, should I…

1) Assume that the system is beyond cleaning/repair (based on the decades since last inverted flight) and order a new separator and valve right off the bat?

2) Plan to order some o-rings and maybe a new ball for the oil valve in the hopes of cleaning it and keeping it in service and replace the separator?

3) Plan to order some o-rings and maybe a new ball for the oil valve in the hopes of cleaning it and keeping it in service and plan to clean the separator?

Thanks!

My question is, should I…

1) Assume that the system is beyond cleaning/repair (based on the decades since last inverted flight) and order a new separator and valve right off the bat?

2) Plan to order some o-rings and maybe a new ball for the oil valve in the hopes of cleaning it and keeping it in service and replace the separator?

3) Plan to order some o-rings and maybe a new ball for the oil valve in the hopes of cleaning it and keeping it in service and plan to clean the separator?

Thanks!