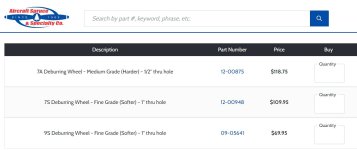

I'm trying to put a 6" 3M C/P 7A-MED Deburring wheel (like the one available from Vans and Cleaveland) on my bench grinder.

I put the first flange on and then the wheel with the reducer bushing (1' to 1/2'). When I try to put on the outer flange there's no smooth arbor left. Only threaded arbor is left exposed and the flange slips into the grooves so it will move about a 1/16' of inch back and forth. There no way to force it stay centered.

Any ideas?

I put the first flange on and then the wheel with the reducer bushing (1' to 1/2'). When I try to put on the outer flange there's no smooth arbor left. Only threaded arbor is left exposed and the flange slips into the grooves so it will move about a 1/16' of inch back and forth. There no way to force it stay centered.

Any ideas?