Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Baffling clean up

- Thread starter Jeff Bost

- Start date

I redid all the baffle seals including the airbox intake thanks to DanH! All the baffle seals were original 2001 installs and were the reinforced rubber. I could see where they were not sealing and many looked wrong to start with. I was hitting 430 and climbing until I would pull power way back around 20” MAP and lower to under 500’/min. Also I was seeing 210 oil temps and climbing until pulling back power. After the replacement baffle seals with the red silicon and RTV in the gaps, I’m now seeing a maximum of 405 at 2500 RPM and 24” MAP – a huge difference. Oil temp isn’t going above 190 in climb. Cruise all under CHTs 365 or under (about 20 degree spread) and oil about 165. Super happy and this was all just old poorly sealing baffle seals!

Last edited:

After the replacement baffle seals with the red silicon and RTV in the gaps, I’m now seeing a maximum of 405 at 2500 RPM and 24” MAP – a huge difference. Oil temp isn’t going above 190 in climb. Cruise all under CHTs 365 or under (about 20 degree spread) and oil about 165. Super happy and this was all just old poorly sealing baffle seals!

Well done Paul.

There is further improvement available in two areas, if you wish.

Pressure in the Inlet is relatively high, something on the order of static pressure plus (ballpark) 70~90% of the available dynamic pressure, so sealing there is particularly important. Unfortunately, most RVs surveyed, including yours, have baffle rubber extending forward from the side and center walls. In most cases pressure pushes the seal away from any contact with the fiberglass cowl. Result is a large leak, often at both the inboard and outboard sides.

Study the inlet sealing in post #49. Note how the rubber strip across the bottom of the inlet extends upward on both sides. It's something like a "U" with a wide base. Also note it is fastened to the lower cowl, and overlaps the side baffle walls. Pressure pushes it against the side walls. A small sheet metal curved fillet improves the profile so the seal can lay in the corner.

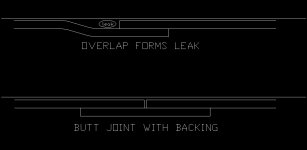

Second improvement would be to install the rear, side, and front seal strips as one piece each, without any overlaps. Each overlap forms a leak area equal to the thickness of the seal material, extending an inch or more from the lap. It's the Catch 22 of silicone seals, as they tend to be thicker than the (miserable) black rubber reinforced seal material.

It's easy to coax unreinforced silicone strip into laying properly along convex curved baffles. Place all the pop rivet holes in the sheet metal. Starting at one end, place a single rivet to begin attaching the silicone. Now stretch the strip slightly, and hold it stretched while you drill through the strip at the next hole. Place the rivet, stretch, drill, repeat. The stretched silicone will naturally curve over and assume the correct shape. How curved can it be and still lay correctly? Here's a Kitfox firewall I did a few years ago. That upper baffle seal is far more curved than anything in the RV world:

Arguably, a builder may wish to put joints in the seal strips at junctions between metal sections, just to ease the job in the event the baffles need to come off for cylinder work. Personally I don't think it adds much work to drill out the soft aluminum pop rivets, but as my dear departed mom liked to say, "To each his own, said the lady who kissed the cow". You want joints in long seal strips? Fine, install them like this:

Jeff Bost

Member

Looks Great! Still working on mine….I redid all the baffle seals including the airbox intake thanks to DanH! All the baffle seals were original 2001 installs and were the reinforced rubber. I could see where they were not sealing and many looked wrong to start with. I was hitting 430 and climbing until I would pull power way back around 20” MAP and lower to under 500’/min. Also I was seeing 210 oil temps and climbing until pulling back power. After the replacement baffle seals with the red silicon and RTV in the gaps, I’m now seeing a maximum of 405 at 2500 RPM and 24” MAP – a huge difference. Oil temp isn’t going above 190 in climb. Cruise all under CHTs 365 or under (about 20 degree spread) and oil about 165. Super happy and this was all just old poorly sealing baffle seals!

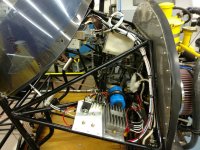

View attachment 70404