So i'm working on the design of my avionics/electrical system and am planning on routing the canbus cable as follows on my RV6 build:

G5 (pilot side)(terminator)

GDU 450 (pilot side)

GTR 200 (center of panel)

GMC 507 (center of panel)

GEA 24 (shelf behind panel)

GAD 27 (shelf behind panel)

GSU 25 (shelf behind panel)

GSA 28 Roll Servo (under seats)

GSA 28 Pitch Servo (bell crank behind baggage bulkhead)

GMU 11 Right or Left Wingtip

I get that the entire canbus run needs to be 66' or under

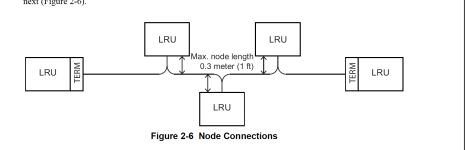

Also in the install manual it says to keep "stub nodes" under 12" - ok, that makes sense until i get to the first A/P servo which obviously will be > 12" from the GSU25 behind the panel....and then it needs to go several more feet to the 2nd A/P servo and then to the end of a wingtip.

I figure I'm not the first person to run into this but it just confuses the heck out of me how you would keep the nodes under 12" when they are at the end of the wingtip....or is the whole "under 12"" think just for the stuff behind the panel?

Thanks!

It all makes sense to me until i get to the first GSA28

G5 (pilot side)(terminator)

GDU 450 (pilot side)

GTR 200 (center of panel)

GMC 507 (center of panel)

GEA 24 (shelf behind panel)

GAD 27 (shelf behind panel)

GSU 25 (shelf behind panel)

GSA 28 Roll Servo (under seats)

GSA 28 Pitch Servo (bell crank behind baggage bulkhead)

GMU 11 Right or Left Wingtip

I get that the entire canbus run needs to be 66' or under

Also in the install manual it says to keep "stub nodes" under 12" - ok, that makes sense until i get to the first A/P servo which obviously will be > 12" from the GSU25 behind the panel....and then it needs to go several more feet to the 2nd A/P servo and then to the end of a wingtip.

I figure I'm not the first person to run into this but it just confuses the heck out of me how you would keep the nodes under 12" when they are at the end of the wingtip....or is the whole "under 12"" think just for the stuff behind the panel?

Thanks!

It all makes sense to me until i get to the first GSA28