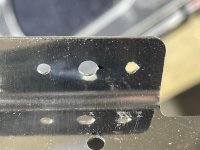

I want to educate myself. I agree with everyone that the quality of these new parts seems to be lacking. My inventory is in the same condition. That said it is how it is and I am building on addressing the worst of the notches. As everyone pointed out its nearly impossible to address every one and it's easy to miss some. I cannot imagine having to replace every part with Van's its simple not feasible. Sometimes I consider stopping the build due to this exact issue and the concern that I will see many issues in the form of cracks done the road.... Then I do some searching on this forum and the whole of the internet. It would seem to me that if this was a major issue you would see all kinds of reports of flying 14s and 10s that had final size holes with cracks appearing. I just haven't seen these reports. Now, that could be that the fleet is so new. That does make some sense. OR could it be that most of this internal structure is not loaded in a way where these notches matter? It would seem that the loading path on these holes may not be significant enough to produce a crack. The rivet, the skin compression against the structure and the multitude of holes spreading the force might be enough to make each notch/hole imperfection enough to make any difference. Now I'm not a materials guy but I am a mechanical engineer and do understand stress concentrations and the notch concerns.

I have to imagine that Van's has considered this issue and is watching all of these posts on this forum. I would hope they would address the problem if it was that much of an issue. They are mostly unconcerned it would seem. I gather this from my own calls with them, this forum, and their lack of addressing the problem. Also I assume the factory built 10s and 14s have the same parts as we do and that they would also see these issues as a safety concern if they were. If this isn't the case then I would highly consider abandoning this build. As it calls into question even the engineering of the design and their safety outlook and procedures.

Lastly, I understand that in a perfect world, the holes would not have these defects. I also understand that some on here are building perfect planes and this is unexceptable for them, but is it a real safety concern or is it just a perfectionist/idealistic view? Like the primer debate, I can't imagine every cessna out there had perfectly polished edges and holes...

I could be way of base. Looking forward to everyone's comments.