AX-O

Well Known Member

All,

In the process of changing from a fixed pitched prop to a constant speed prop, I have ran into one major issue. Hoping to have a thread that folks can view and use to make a decision before heading down this road.

If you are a moderator, please consider making this a sticky. It will save someone thousands of dollars and many weeks of troubleshooting and backtracking.

STOP!!!! before you even think about doing this conversion, some very costly advice i had to learn on my own (even though the info is out on VAF on various threads if you look around).

All engine cases are not crated equal. Make sure you know what type of case you have and how it has been configured. Just because you have a hallow crank does not mean you can convert to constant speed by adding a governor and associated line, gasket, pad, etc.

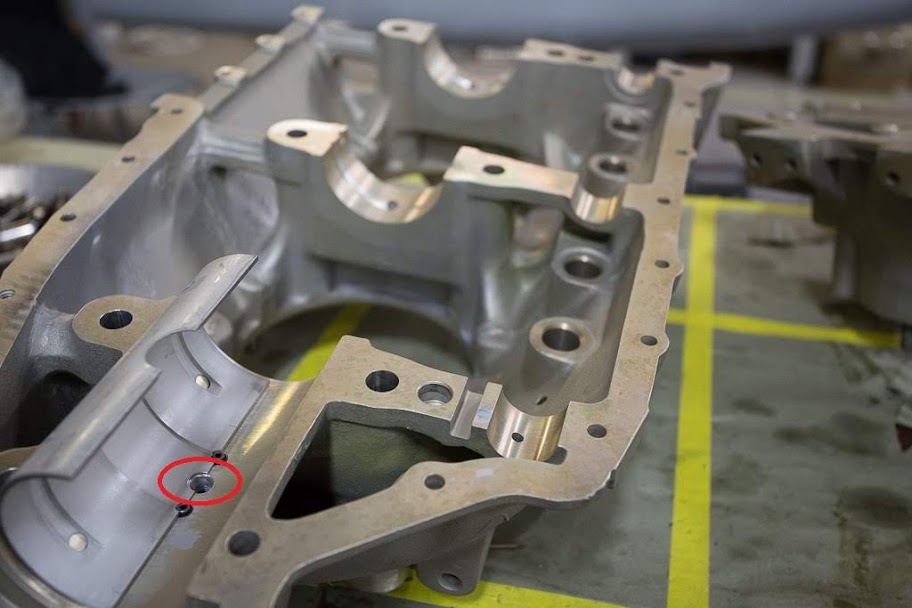

Some engine cases have a port/hole on the left engine case half. (Example picture, not my engine)

Some do not. (Example picture, not my engine)

That little hole not being plugged with an NPT plug will allow the pressure created by the prop governor to escape into the engine case. NOT GOOD for constant speed operations.

This topic has been discuss here previously but I missed it. Below are a few links:

click

Click

After reinstalling my engine and being ready to fly, my prop was taking a long time to cycle. At some point during the ground check the prop stopped cycling. Oil temp was at approx 170 deg. After reading, researching and trouble shooting I came up with a plan.

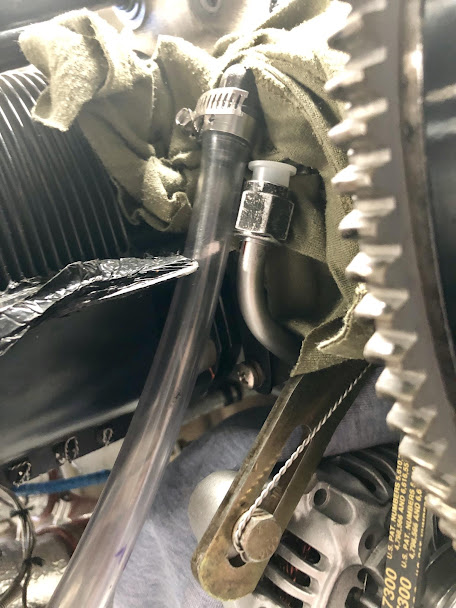

I used the 90 deg fitting on the nose of the engine and put air pressure to it vice oil pressure from the prop governor. The result was air immediately rushing out of the case vent and the oil dip stick (if I opened it), the prop would not move. Since the plug inside of the crank is in place and did not have a hole (correct for constant speed configuration); either the NPT plug is not in, the front bearing is not installed correctly or the inner crank plug is leaking.

At this point the best case scenario is I remove the prop and the inner crank plug is not on right. but it looks like the engine is coming off again and going to an engine shop to get tore down. Pics below of the set up used to put air pressure in the 90 deg fitting.

In the process of changing from a fixed pitched prop to a constant speed prop, I have ran into one major issue. Hoping to have a thread that folks can view and use to make a decision before heading down this road.

If you are a moderator, please consider making this a sticky. It will save someone thousands of dollars and many weeks of troubleshooting and backtracking.

STOP!!!! before you even think about doing this conversion, some very costly advice i had to learn on my own (even though the info is out on VAF on various threads if you look around).

All engine cases are not crated equal. Make sure you know what type of case you have and how it has been configured. Just because you have a hallow crank does not mean you can convert to constant speed by adding a governor and associated line, gasket, pad, etc.

Some engine cases have a port/hole on the left engine case half. (Example picture, not my engine)

Some do not. (Example picture, not my engine)

That little hole not being plugged with an NPT plug will allow the pressure created by the prop governor to escape into the engine case. NOT GOOD for constant speed operations.

This topic has been discuss here previously but I missed it. Below are a few links:

click

Click

After reinstalling my engine and being ready to fly, my prop was taking a long time to cycle. At some point during the ground check the prop stopped cycling. Oil temp was at approx 170 deg. After reading, researching and trouble shooting I came up with a plan.

I used the 90 deg fitting on the nose of the engine and put air pressure to it vice oil pressure from the prop governor. The result was air immediately rushing out of the case vent and the oil dip stick (if I opened it), the prop would not move. Since the plug inside of the crank is in place and did not have a hole (correct for constant speed configuration); either the NPT plug is not in, the front bearing is not installed correctly or the inner crank plug is leaking.

At this point the best case scenario is I remove the prop and the inner crank plug is not on right. but it looks like the engine is coming off again and going to an engine shop to get tore down. Pics below of the set up used to put air pressure in the 90 deg fitting.

Last edited: