I love to learn. That's one of the things that got me into the airplane building thing. It's also taught me that there's a lot I have yet to learn...

I have a lycoming o-360, 675 hours SNEW, but was recently rebuilt (by me) in response to a prop strike. Case professionally cleaned, cam and crank polished, tappets overhauled, new bearings, overhauled jugs, new pistons, piston pins, etc. It now has about 75 hours on it since the rebuild. These 75 hours have been accrued over the past 9 months.

The engine uses virtually no oil, and has made good compression (78+/80 at 10 and 50 hours, haven't checked it since), and runs smooth and strong. Oil temps are a little low, but fine and pressure is about 80psi in cruise, 60 at idle.

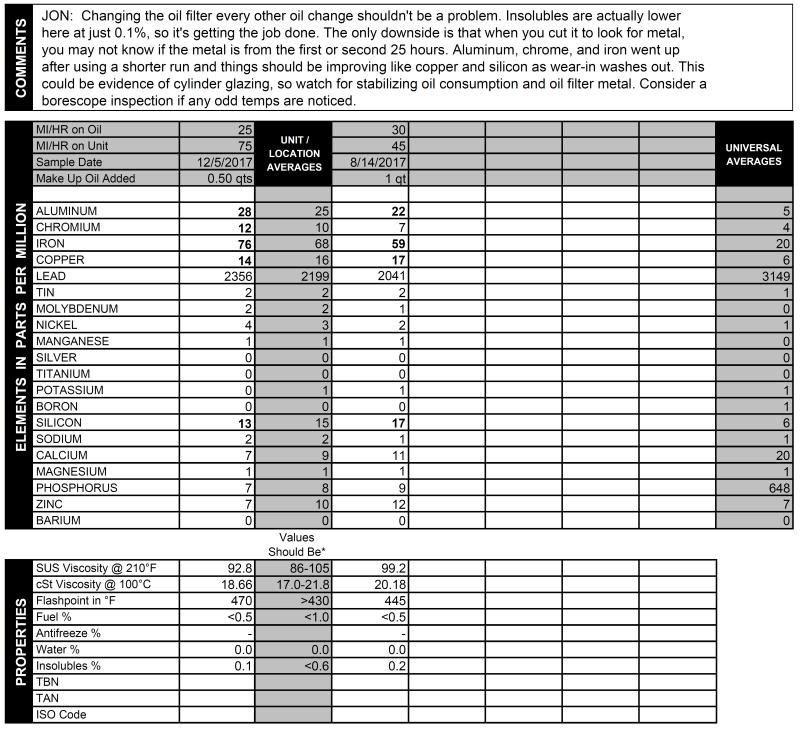

After the rebuild, I ran the engine for about 10 hours, then replaced the oil and filter. I didn't have the oil analyzed (I said I had lots to learn), but did open up the filter and didn't notice any metal of any kind in it. I didn't wash the filter with mineral spirits or anything, so it could be that i just didn't notice but there was some there. Between 25 & 30 hours later, I drained the oil, but did not replace the filter. I was told that the filter was good for 50 hours, so i thought i'd only replace it every other time. In retrospect, this might be fine later down the road, but was foolish at the very beginning of the run in that the filter could have provided useful information. I did, however, send off a sample of the oil to Blackstone for analysis. Metals were a little high, but that was expected for an engine just breaking in. Fast forward to about 2 weeks ago. 25 hours have passed and it's time for another oil change. This time oil and filter were changed. Oil was sent off, and the filter sat in the bucket waiting for me to get around to checking it. Report came back that iron and aluminum had actually increased slightly, and after only 25 hours instead of 30. Alarmed, I immediately cut open the filter to inspect it, and have lots of miniscule shiny non-ferrous bits in there as well as a couple half-inch long hairlike slivers of ferrous metal. I'd guess there's a shiny speck in almost every pleat, and a few pleats with quite a few. They're embeded in there, so collecting them for a teaspoon reading isn't going to happen... Running a magnet over the filter reveals virtually no iron dust or anything else.

What I don't know is:

Do I have a major problem that has trashed my bearings already, or am I totally flipping out over absolutely nothing?

Is this typical metal wear for a new engine and a filter with 50 hours on it?

One helpful avweb article mentioned flakes of aluminum and hairs of steel pointed to a broken ring. I have a borescope and wonder what I should be looking for in that regard?

The plan right now is to scope the cylinders the next time I'm at the airport, then run for ten more hours before pulling the filter for inspection.

Here is a video that shows the filter, and it really doesn't do it justice. Every little white speck is a shiny piece of metal.

https://youtu.be/2APnb5haYak

And the oil Analysis:

I have a lycoming o-360, 675 hours SNEW, but was recently rebuilt (by me) in response to a prop strike. Case professionally cleaned, cam and crank polished, tappets overhauled, new bearings, overhauled jugs, new pistons, piston pins, etc. It now has about 75 hours on it since the rebuild. These 75 hours have been accrued over the past 9 months.

The engine uses virtually no oil, and has made good compression (78+/80 at 10 and 50 hours, haven't checked it since), and runs smooth and strong. Oil temps are a little low, but fine and pressure is about 80psi in cruise, 60 at idle.

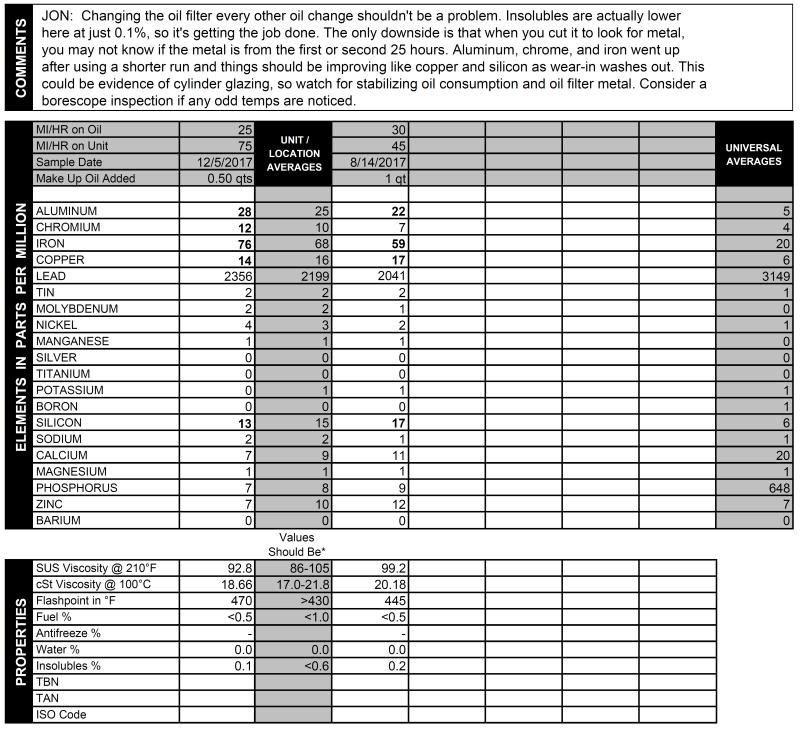

After the rebuild, I ran the engine for about 10 hours, then replaced the oil and filter. I didn't have the oil analyzed (I said I had lots to learn), but did open up the filter and didn't notice any metal of any kind in it. I didn't wash the filter with mineral spirits or anything, so it could be that i just didn't notice but there was some there. Between 25 & 30 hours later, I drained the oil, but did not replace the filter. I was told that the filter was good for 50 hours, so i thought i'd only replace it every other time. In retrospect, this might be fine later down the road, but was foolish at the very beginning of the run in that the filter could have provided useful information. I did, however, send off a sample of the oil to Blackstone for analysis. Metals were a little high, but that was expected for an engine just breaking in. Fast forward to about 2 weeks ago. 25 hours have passed and it's time for another oil change. This time oil and filter were changed. Oil was sent off, and the filter sat in the bucket waiting for me to get around to checking it. Report came back that iron and aluminum had actually increased slightly, and after only 25 hours instead of 30. Alarmed, I immediately cut open the filter to inspect it, and have lots of miniscule shiny non-ferrous bits in there as well as a couple half-inch long hairlike slivers of ferrous metal. I'd guess there's a shiny speck in almost every pleat, and a few pleats with quite a few. They're embeded in there, so collecting them for a teaspoon reading isn't going to happen... Running a magnet over the filter reveals virtually no iron dust or anything else.

What I don't know is:

Do I have a major problem that has trashed my bearings already, or am I totally flipping out over absolutely nothing?

Is this typical metal wear for a new engine and a filter with 50 hours on it?

One helpful avweb article mentioned flakes of aluminum and hairs of steel pointed to a broken ring. I have a borescope and wonder what I should be looking for in that regard?

The plan right now is to scope the cylinders the next time I'm at the airport, then run for ten more hours before pulling the filter for inspection.

Here is a video that shows the filter, and it really doesn't do it justice. Every little white speck is a shiny piece of metal.

https://youtu.be/2APnb5haYak

And the oil Analysis:

Last edited: